Loading ...

Loading ...

Loading ...

Part number 550-100-400/0119

74

Sidewall vent/air termination: 3” or 4” concentric (cont.)

®

Series 4

gas-fired water boiler — Boiler Manual

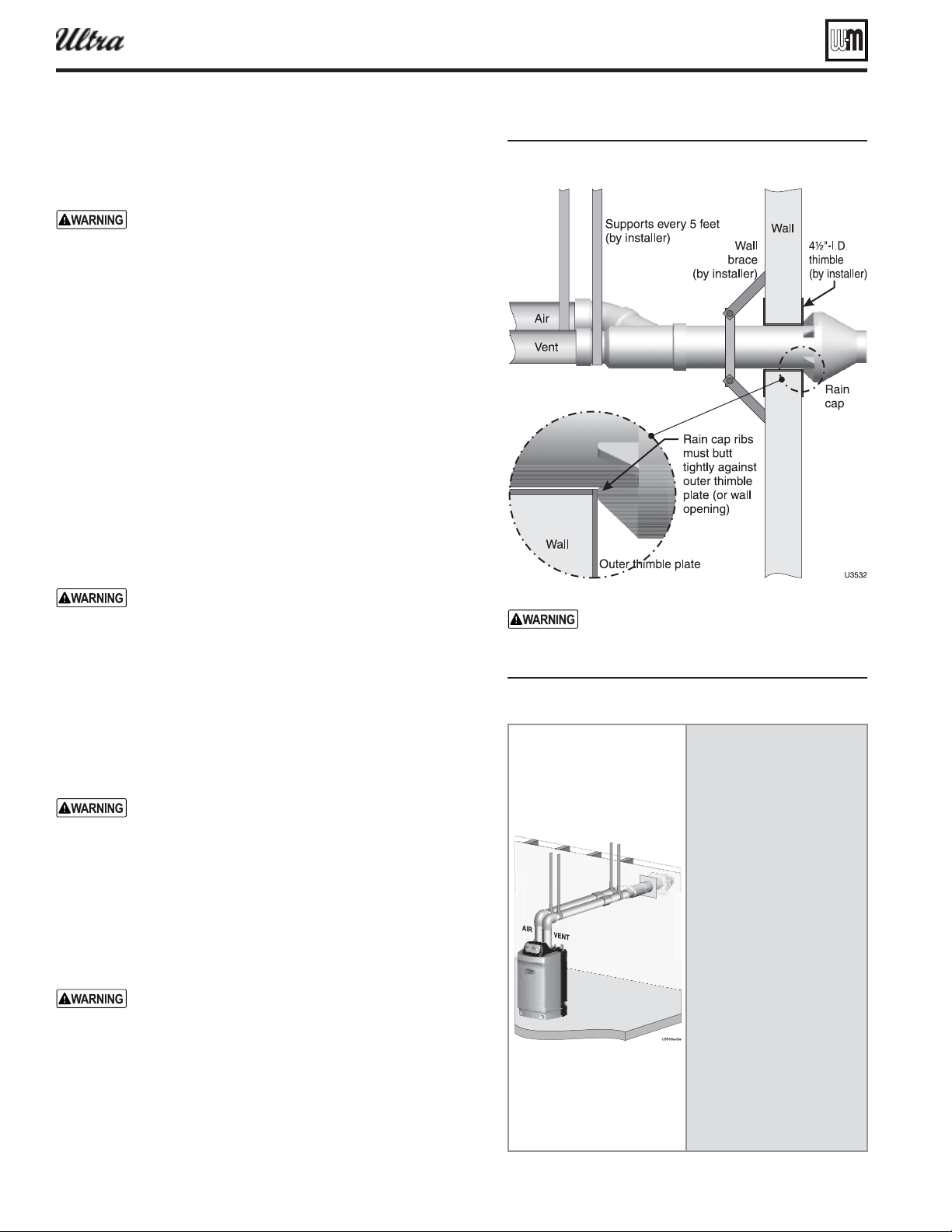

Figure 82 Installin and supportin the concentric

sideall ent asseml

Figure 83

Ensure that the wall material is strong enough

to prevent the rain cap from being pushed

inward if struck or pushed from the outside.

Install terminations — concentric pipes

1. Assemble the vent termination as described for vertical concen-

tric terminations, beginning on page 76 .

If necessary, you can shorten the lengths of the inner

and outer pipes for a shorter fi nished assembly. But

you must ensure the pipes butt correctly at both ends.

Failure to properly assemble the concentric termina-

tion can result in fl ue gas recirculation, causing possible

severe personal injury or death.

2. Wall penetration:

a. 3” termination: Preferably, use a thimble with a 4½-inch

hole. If not using a thimble, carefully use a hole saw to cut a

hole not larger than 4¾ inches in diameter through the wall.

The fi nished hole must provide a solid stop for the rain cap

ribs, as shown in the inset to Figure 82 .

b. 4” termination: Preferably, use a thimble with a 6-inch hole.

If not using a thimble, carefully use a hole saw to cut a hole

not larger than 6¼ inches in diameter through the wall. The

fi nished hole must provide a solid stop for the rain cap ribs,

as shown in the inset to Figure 82 .

3. Secure the termination in place so the rain cap will butt against

the outside wall or outer thimble plate as shown in Figure 82 .

4. Before beginning vent and air piping from the boiler to the

concentric termination, mount and secure the concentric ter-

mination as shown in Figure 82 and Figure 105 .

The vent and air piping must be securely supported,

and must not rest its weight on the boiler fi ttings. Fail-

ure to properly support the vent and air piping could

result in vent piping damage, resulting in possible

severe personal injury, death or substantial property

damage.

The supports/bracing used must support the termina-

tion assembly to prevent slippage or movement.

The clamps used on the outside of the termination pipe

must not cut into the pipe or contain sharp edges that

could cause a crack to form.

When inserting the partially-assembled termination

kit through the roof penetration, wrap plastic or

other protection over the end of the exposed assembly

to prevent debris from entering the pipes. If the air

passages become blocked, the boiler will not operate.

Once the rain cap has been cemented to the assembly,

there is no way to correct the problem. The assembly

would have to be replaced if it were cut to be removed

and cleaned. Altering the assembly in any way could

result in severe personal injury or death due to toxic

fl ue product emissions.

When using AL29-4C stainless vent pipe, use the vent

pipe manufacturer’s PVC adapter when connecting to

the concentric vent attachment.

5. After the assembly has been positioned in the opening and all

supports have been attached, install a bird screen (purchased

separately if not included with the kit) and rain cap as follows:

a. Place the bird screen on the end of the inner pipe as in Fig-

ure 89, page 78 .

b. Cement the rain cap in place as shown.

installin termination see

pae

Install pipe supports every 5 feet

on both the horizontal and verti-

cal runs.

Install a hanger support within

6 inches of any upturn in the

piping.

Support the termination

at the wall as shown in the

termination instructions.

Slope horizontal piping

downward toward the boiler at

least 1/4 inch per foot.

Rotate the concentric

termination Y-fi tting about

30° to result in pipe centers the

same as at the boiler.

Loading ...

Loading ...

Loading ...