Loading ...

Loading ...

Loading ...

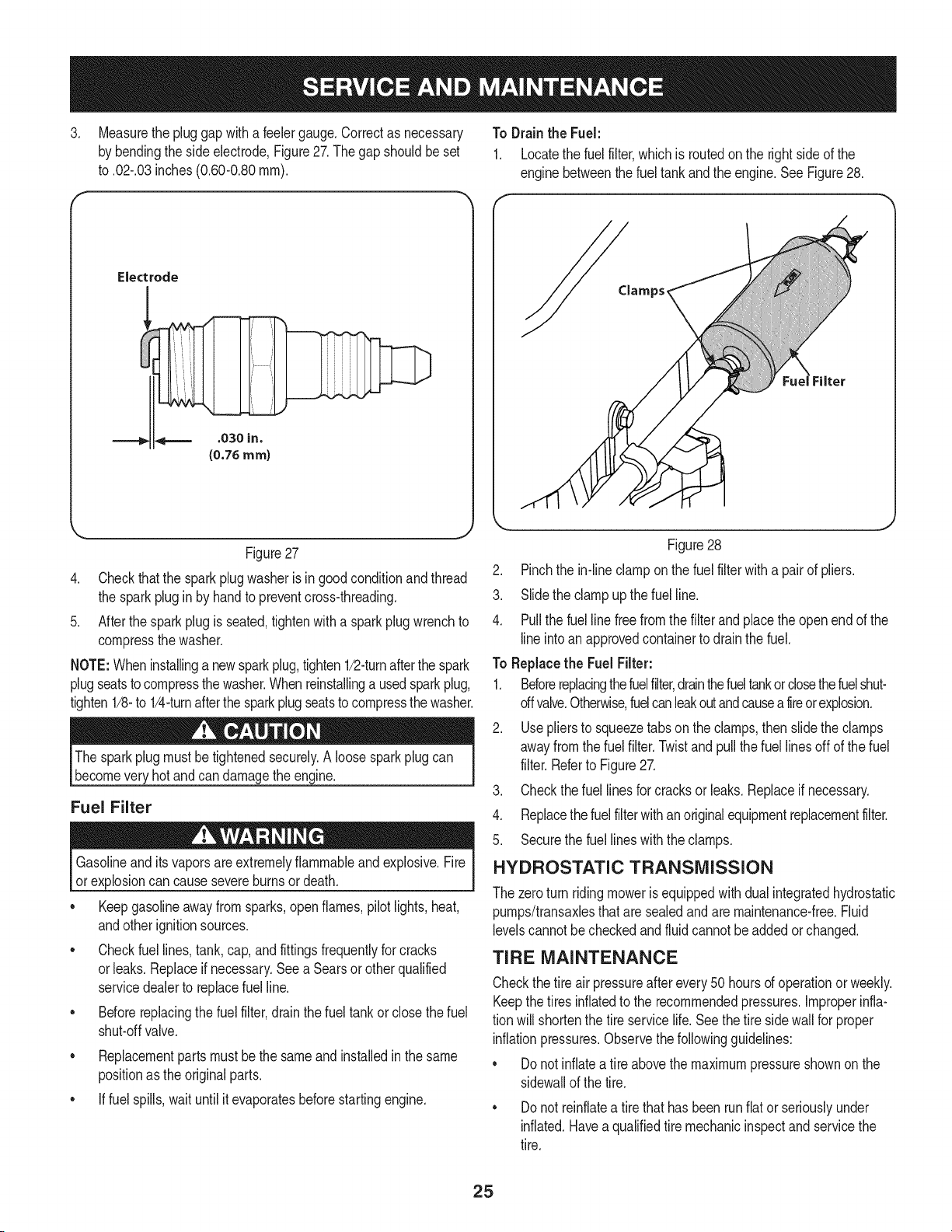

3. Measurethe pluggapwitha feelergauge.Correctas necessary To Drain the Fuel:

by bendingthe side electrode,Figure27.Thegapshouldbe set 1. Locatethe fuel filter,whichis routedonthe right sideof the

to .02-.03inches(0.60-0.80ram). enginebetweenthe fueltankandthe engine.See Figure28.

Electrode

.030 in.

(0.76 ram)

Clamps_

Figure27

4. Checkthatthe sparkplugwasheris in good conditionand thread

the sparkplugin by handto preventcross-threading.

5. Afterthespark plug is seated,tightenwith a spark plugwrenchto

compressthe washer.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe spark

plugseatstocompressthewasher.Whenreinstallinga usedsparkplug,

tighten1/8-to 1/4-turnafterthe sparkplugseatsto compressthewasher.

The sparkplugmustbetightenedsecurely.A loosesparkplug can

becomevery hotandcan damagethe engine.

Fuel Filter

Gasolineandits vaporsare extremelyflammableandexplosive.Fire

or explosioncan causesevereburnsor death.

• Keepgasolineawayfrom sparks,open flames,pilotlights,heat,

andotherignitionsources.

• Checkfuellines,tank,cap, and fittingsfrequentlyfor cracks

orleaks.Replaceif necessary.Seea Searsor other qualified

servicedealerto replacefuel line.

• Beforereplacingthe fuel filter,drain the fueltank or closethe fuel

shut-offvalve.

• Replacementpartsmustbe the same and installedin the same

positionas the originalparts.

• If fuelspills,wait until it evaporatesbeforestartingengine.

Figure28

2. Pinchthe in-line clampon the fuel filter with a pairof pliers.

3. Slidethe clampup thefuel line.

4. Pullthe fuel line freefrom the filter and placethe open end of the

lineintoanapprovedcontainerto drainthe fuel.

To Replacethe Fuel Filter:

1. Beforereplacingthefuelfilter,drainthefueltankor closethefuelshut-

offvalve.Otherwise,fuelcanleakoutandcausea fireor explosion.

2. Usepliersto squeezetabson the clamps,thenslidethe clamps

awayfromthe fuelfilter.Twistandpullthe fuel linesoffof thefuel

filter.Referto Figure27.

3. Checkthe fuel linesforcracks or leaks.Replaceif necessary.

4. Replacethefuel filterwithan originalequipmentreplacementfilter.

5. Securethe fuellineswith the clamps.

HYDROSTATIC TRANSMISSION

The zeroturn ridingmoweris equippedwithdualintegratedhydrostatic

pumps/transaxlesthatare sealedand are maintenance-free.Fluid

levelscannotbecheckedandfluidcannotbe added or changed.

TIRE MAINTENANCE

Checkthe tire airpressureafterevery50 hoursof operationorweekly.

Keepthetires inflatedto the recommendedpressures.Improperinfla-

tion will shortenthe tireservicelife.Seethe tire sidewallfor proper

inflationpressures.Observethe followingguidelines:

• Donot inflatea tire abovethe maximumpressureshownon the

sidewallof the tire.

• Donot reinflatea tire thathas been runflat or seriouslyunder

inflated.Haveaqualifiedtire mechanicinspectand servicethe

tire.

25

Loading ...

Loading ...

Loading ...