Loading ...

Loading ...

Loading ...

Lower Deck Discharge Chute Deflector Checking Tire Pressure

Neveroperatethe mowerdeckwithoutthe chutedeflectorinstalled

andin the downposition.

Thedischargechutedeflectormustbe installedbeforeoperatingthe

mower.

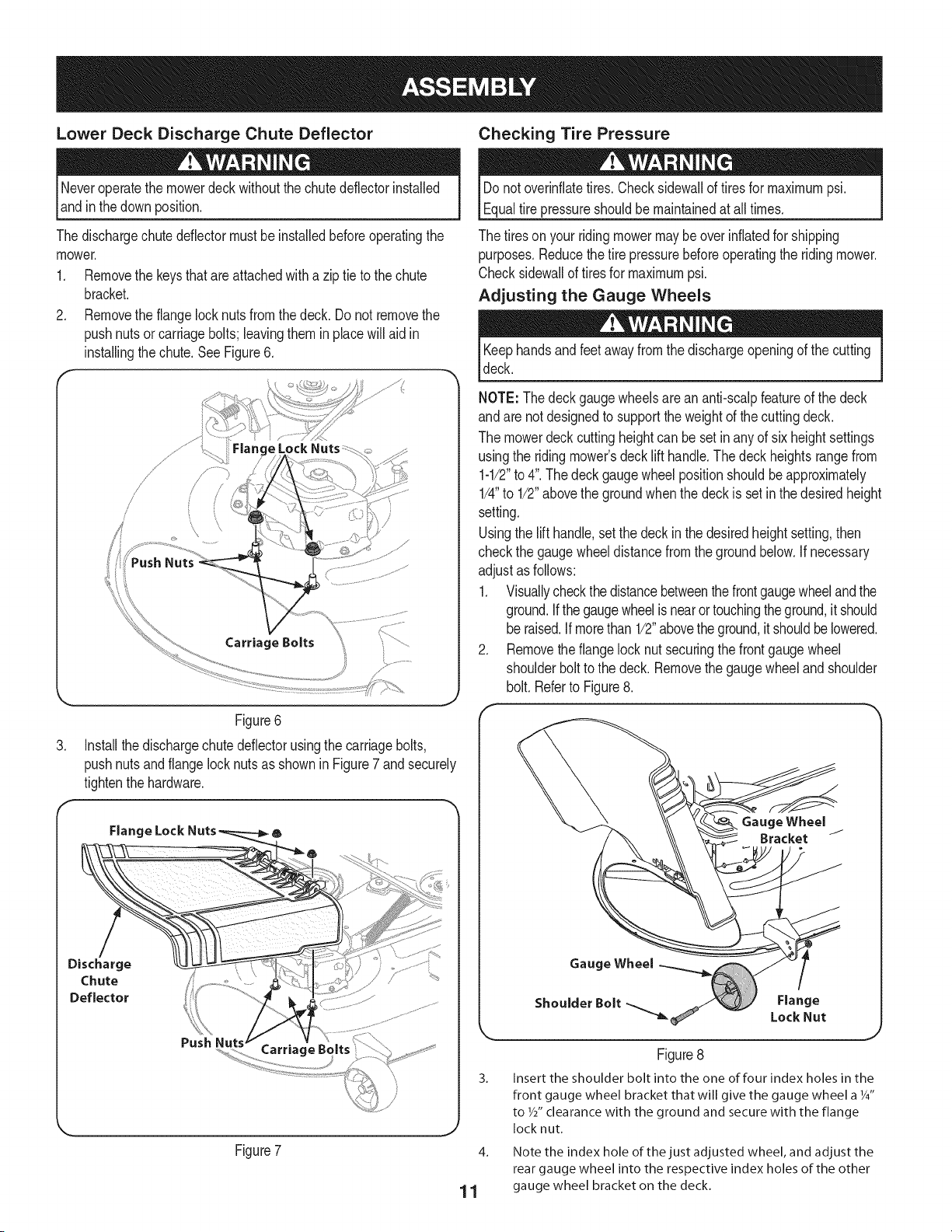

1. Removethe keysthat are attachedwith a zip tie to the chute

bracket.

2. Removethe flangelock nuts from thedeck. Do not removethe

pushnutsor carriagebolts;leavingthem in placewill aid in

installingthe chute.SeeFigure6.

,//

/

/

/

/

/

Carriage Bolts

Figure6

3. Installthedischargechutedeflectorusingthe carriagebolts,

pushnutsand flangelock nuts as shownin Figure7 and securely

tightenthe hardware.

Flange Lock 6

Discharge

Chute

Deflector

Push

Carriage Bc

Figure7

J

Donot overinflatetires.Checksidewallof tiresfor maximumpsi.

Equaltire pressureshouldbe maintainedat all times.

The tiresonyour ridingmowermaybe overinflatedfor shipping

purposes.Reducethetire pressurebeforeoperatingthe ridingmower.

Checksidewallof tiresfor maximumpsi.

Adjusting the Gauge Wheels

Keephandsandfeet awayfrom the dischargeopeningof the cutting

deck.

NOTE: Thedeckgaugewheelsarean anti-scalpfeatureof the deck

andare notdesignedto supportthe weightof the cuttingdeck.

The mowerdeckcuttingheightcan be set in anyof six heightsettings

usingthe ridingmower'sdecklift handle.The deckheightsrangefrom

1-1/2"to 4".The deckgaugewheelpositionshouldbeapproximately

1/4"to 1/2"abovethe groundwhenthe deck is set in thedesiredheight

setting.

Usingthe lifthandle,setthe deck in the desiredheightsetting,then

checkthe gaugewheeldistancefromthe groundbelow.If necessary

adjustasfollows:

1. Visuallycheckthe distancebetweenthefrontgaugewheelandthe

ground.Ifthe gaugewheelis nearortouchingtheground,it should

be raised.If morethan1/2"abovetheground,it shouldbe lowered.

2. Removethe flangelock nut securingthe frontgauge wheel

shoulderboltto the deck.Removethe gaugewheelandshoulder

bolt. Referto Figure8.

Gauge Wheel

3_

Gauge Wheel

Flange

ShoulderBolt _ LockNut

Figure8

Insert the shoulder bolt into the one of four index holes in the

front gauge wheel bracket that will give the gauge wheel a Y4"

to W' clearance with the ground and secure with the flange

locknut.

4. Note the index hole of the just adjusted wheel, and adjust the

rear gauge wheel into the respective index holes of the other

1 1 gauge wheel bracket on the deck.

Loading ...

Loading ...

Loading ...