Loading ...

Loading ...

Loading ...

51

Refrigerant Piping Connections

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

REFRIGERANT PIPING CONNECTIONS

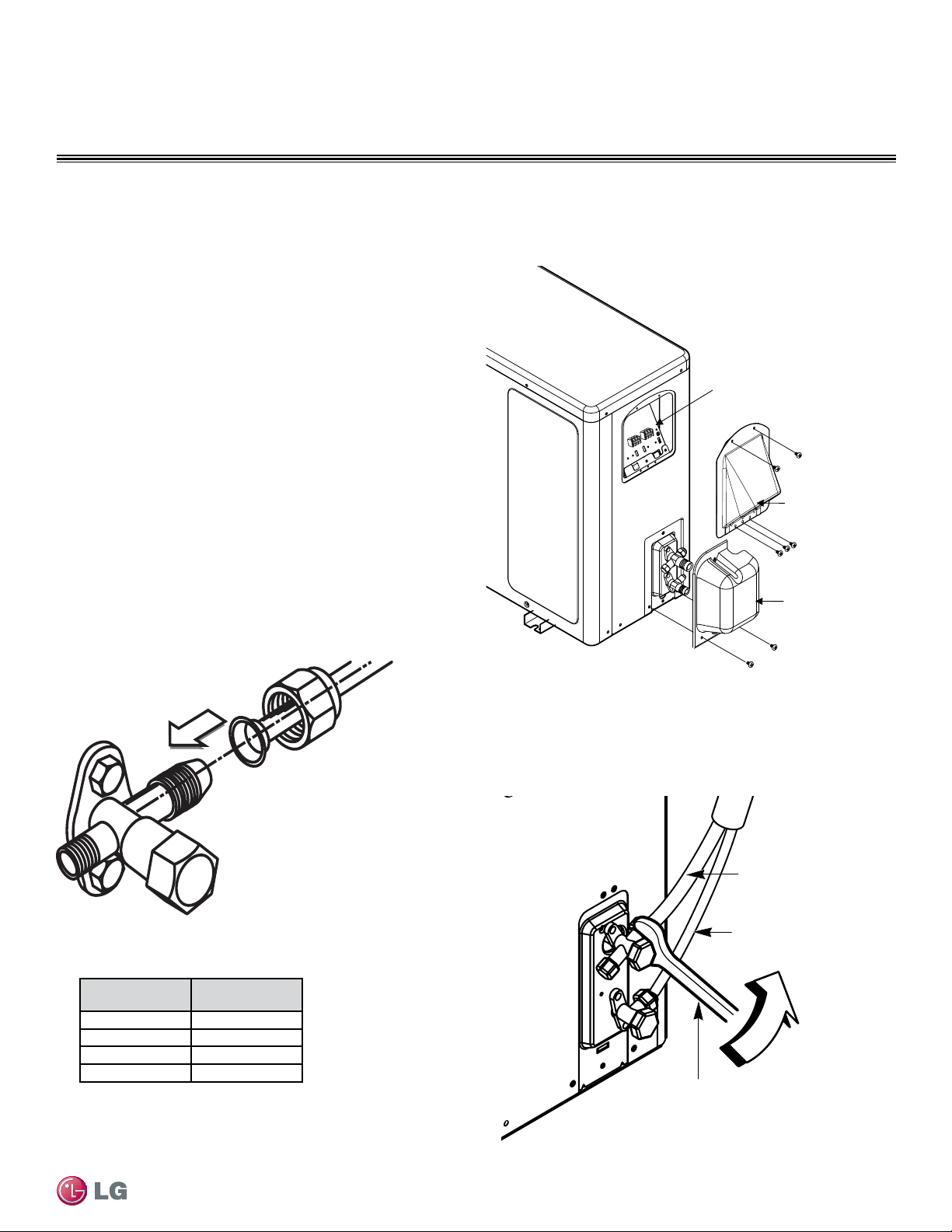

Outdoor Unit

Torque wrench

Liquid Piping

(Smaller diameter)

Gas Piping

(Larger diameter)

Single Zone Wall Mount Outdoor Unit Connections (240HEV)

Tubing

Cover

Conduit Panel

Cover

Terminal Block

240HEV

Screw

Outdoor Unit Connections

Figure 55: Outdoor Unit Cover Removal (240HEV)

Figure 57: Outdoor Unit Piping Connection (240HEV)

1. Remove the tubing cover by loosening the fastening screws (Figure 55).

2. Align the center of the refrigerant pipe and corresponding

connection as shown in Figure 56.

3. Refer to Figure 57 for correct liquid and gas pipe attachment onto

outdoor unit.

4. Place a couple of drops of refrigerant oil on the opening rim of the

flare before assembling. Ensure you do not add any

contaminants. Tighten the flare nut initially by hand.

5. Finish tightening the flare nut with a torque wrench until the wrench

clicks. Follow torque guidelines in Table 27.

Figure 56: Pipe Attachment

Table 27: Torque Wrench Tightening

Outside Diame-

ter (inches)

Torque (lbs-ft)

1/4

13-18

3/8

24.6-30.4

1/2

39.8-47.7

5/8

45.6-59.3

Loading ...

Loading ...

Loading ...