Loading ...

Loading ...

Loading ...

BOTH MODELS

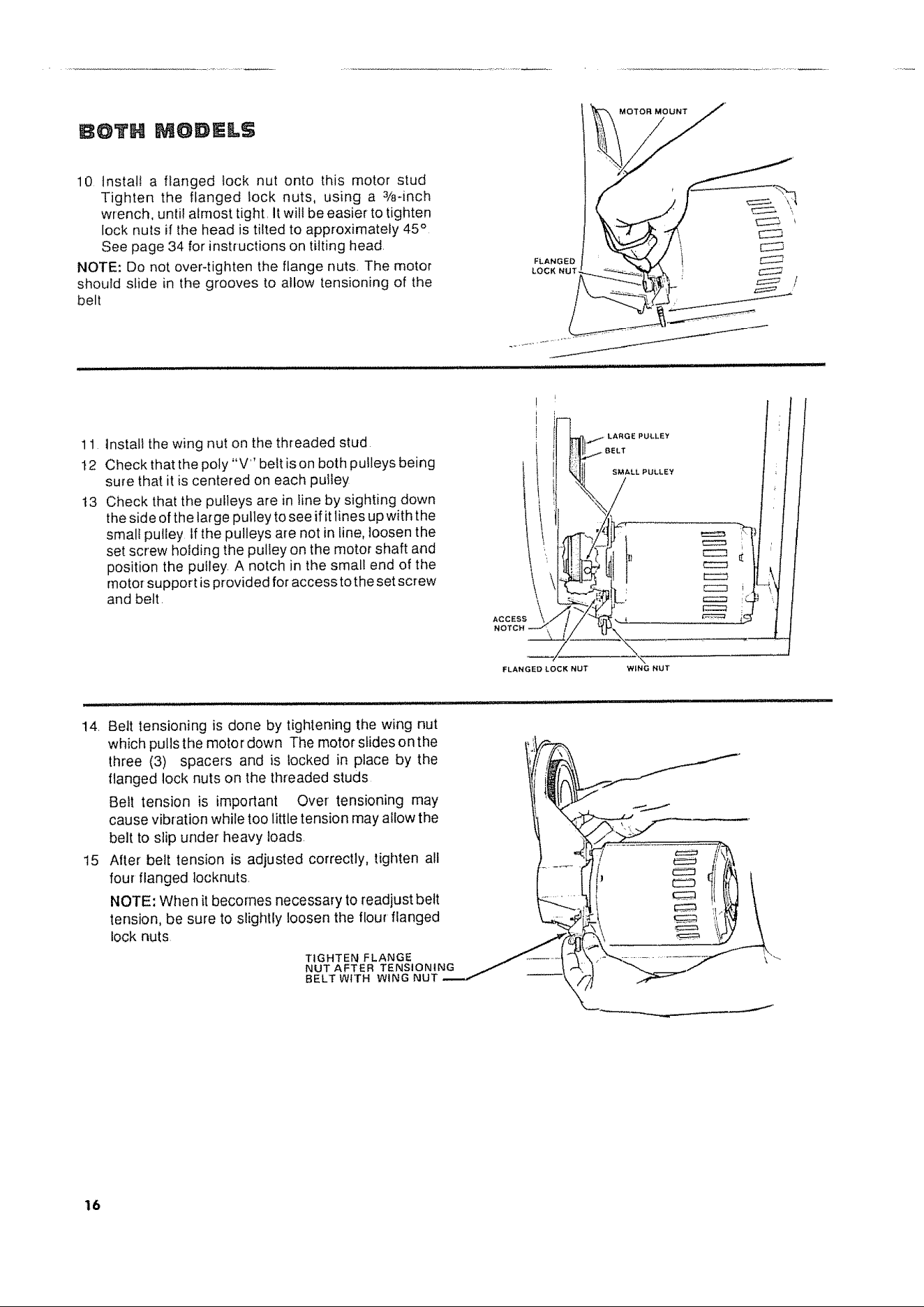

10 Install a flanged lock nut onto this motor stud

Tighten the flanged lock nuts, using a 3/8-inch

wrench, until almost tight, It will be easier to tighten

lock nuts if the head is tilted to approximately 45°

See page 34 for instructions on tilting head,

NOTE: Do not over-tighten the flange nuts The motor

should slide in the grooves to allow tensioning of the

belt

11 Install the wing nut on the threaded stud

t2 Check that the poly "V" belt ison both pulleys being

sure that it is centered on each pulley

t3 Check that the pulleys are in line by sighting down

the side ofthe large pulley to see if itlines up with the

small pulley If the pulleys are not in line, loosen the

set screw holding the pulley on the motor shaft and

position the puiley, A notch in the small end of the

motoTsupport is provided for access tothe set screw

and belt.

FLANGED

LOCK NUT

MOTOR MOUNT

ACCESS

NOTCH

FLANGED LOCK NUT WING NUT

14, Belt tensioning is done by tightening the wing nut

which pulls the motor down The motor slides on the

three (3) spacers and is locked in place by the

flanged lock nuts on the threaded studs

Belt tension is important Over tensioning may

cause vibration while too little tension may allow the

belt to slip under heavy loads,

15 Alter belt tension is adjusted correctly, tighten all

four flanged locknuts

NOTE: When it becomes necessary to readjust belt

tension, be sure to slightly loosen the flour flanged

lock nuts

TIGHTEN FLANGE

NUT AFTER TENSIONING

BELTWITH WtNGNUT

16

Loading ...

Loading ...

Loading ...