Loading ...

Loading ...

Loading ...

43

ZKHTSS1 for 3/4" Panels

Tubulor Stainless Steel Handles

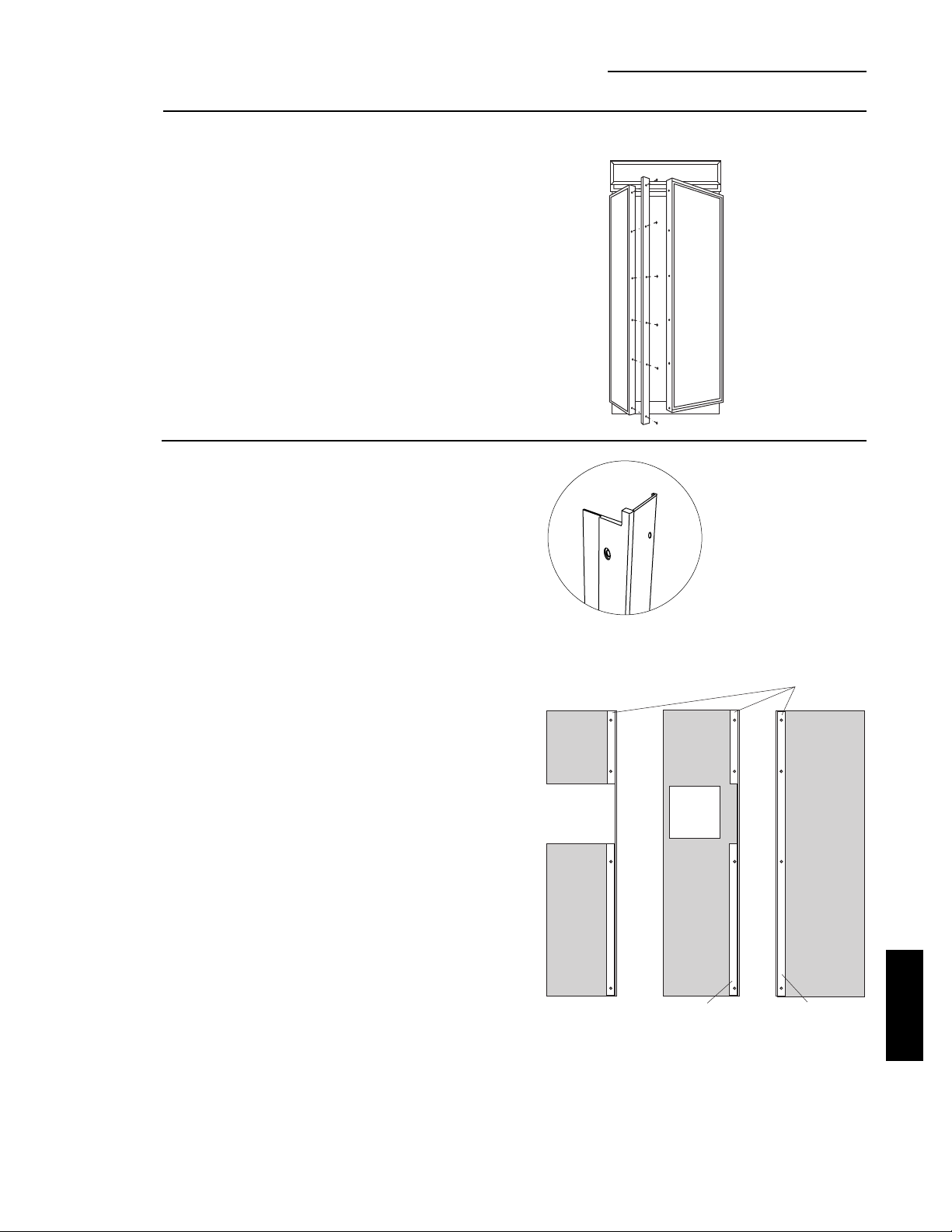

Step 2:

Match

Handle Extrusions

to Panels

• Cut a piece of corrugated to use as a pad to protect

the panel finish. Use 1/2" thick section of plywood to

protect flooring when drilling.

• Place custom panels on the pad, appearance side

down.

Note:

If panels are wood, be sure to note which end is

the top so that wood grain is in the correct direction

on both (or all 3) panels.

• Place new extrusion against the handle side of the

panels.

• Align the extrusion evenly with the top and bottom of

the panel.

• Follow the same procedure on the opposite panel.

• Tape the extrusions to the panels to prevent

movement.

• Center punch and drill 1/8" pilot holes through the

holes in the extrusion and into the panel.

• Turn panel over. On the appearance side, use 9/32" bit

to enlarge clearance hole.

IMPORTANT:

Hole locations must be exact to accept handle

standoff and handle assembly.

For models with full width dispenser trim and 2 piece

freezer panels:

• Carefully, align the top of the upper panel and the

bottom of the lower panel with extrusion ends.

Note:

Be sure to orient

extrusions and handles

correctly. The top ends of

the extrusions are cutout to fit

the shape of the top of the

door.

Top

End

Step 1:

Remove

Handles

• Carefully remove the phillips head screws from the

door handle top endcaps, if present.

• Open doors to 90°. Remove the screws from the full-

length handles of both doors.

• Retain screws, discard handles and endcaps.

Note:

If a custom collar is to be used, order ZWCD1

Trim Kit for 36" and 42" wide models. Order ZWCD2 for

48" wide models.

Back

Side

Freezer

Panel

Freezer

Extrusion

Back

Side

Freezer

Lower

Panel

Freezer

Upper

Panel

Models

With Full Width

Dispenser Trim

Fresh Food

Extrusion

Align Extrusion

Even With

Panel

Back

Side

Fresh

Food

Panel

ZKHTSS1

INSTALLATION

Loading ...

Loading ...

Loading ...