Loading ...

Loading ...

Loading ...

Installation & Owner’s Guide 15

4. Inspection/Testing Continued

Tile, Stone, and Marble Installation

When installing Peel & Stick Radiant Heat Film under tile, stone, or marble, we highly recommend Tile Counil of

North America (TCNA) guidelines or ANSI specifications for minimum standards of installation. We recommend

latex-modified or epoxy modified mortar and grout, instead of water-based multi-purpose materials.

Use full coverage of thin set with no voids. Spot Bonding (Dot Mounting), and leaving large voids, is unacceptable

and will lead to a crunching noise where the heat mats are installed. Thin set must be installed following TCNA/

ANSI standards. Spot bonding of tile that only gives partial contact leaving large voids is not an acceptable

method for tile installed on floors with thin-set mortars.

Select the proper size PLASTIC trowel for the installation of tile or stone. We recommend a minimum 3/8” x 1/4”

trowel. This trowel works best for most 1/4” tile.

If you need more information on tile installation, contact TCNA at (864) 646-8453 or visit their Web site at www.tileusa.com.

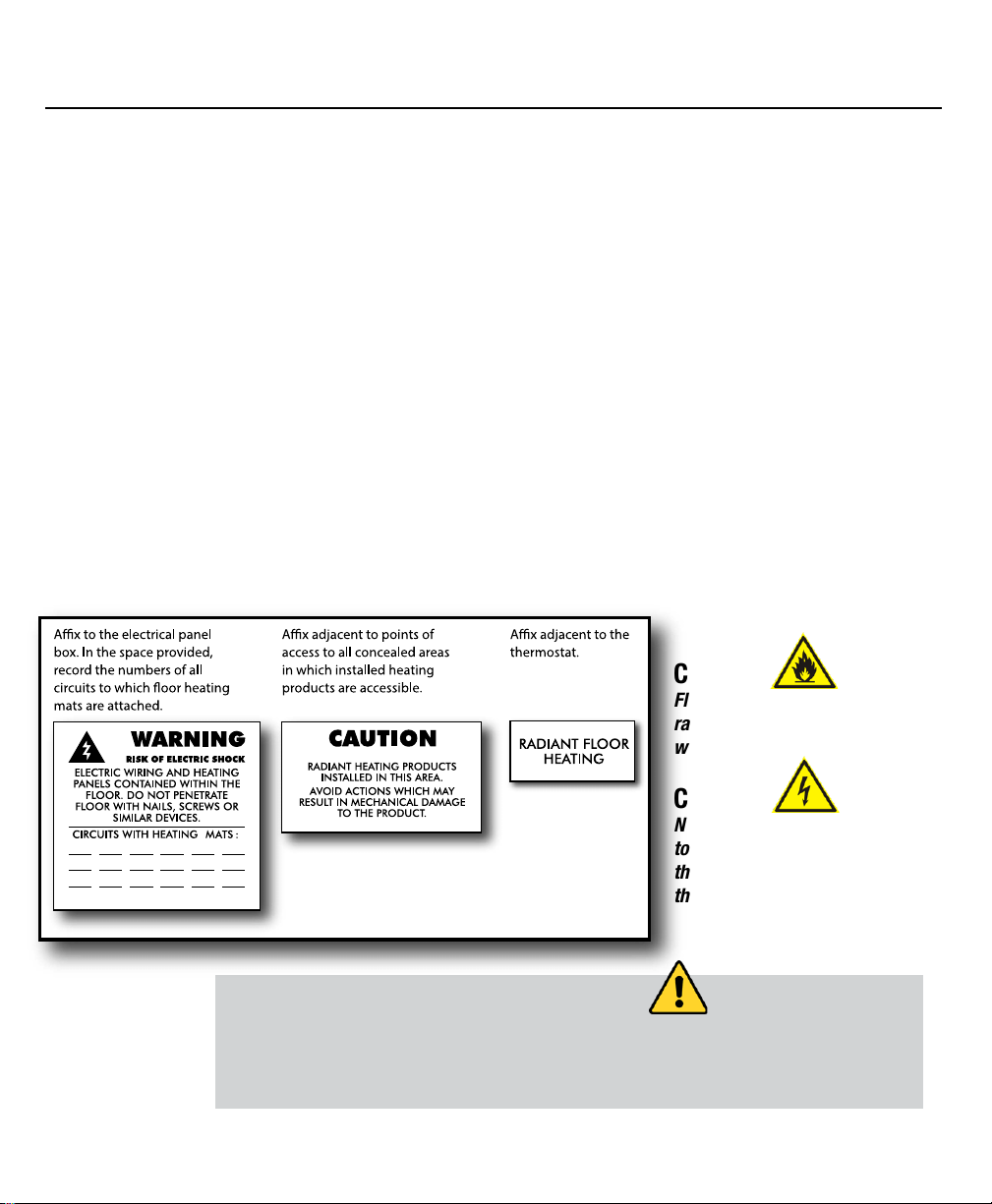

Place Caution Stickers

Apply caution stickers provided with mats in appropriate locations, as shown below.

NOTE:

When installing tile, stone or marble over Peel & Stick Radiant Heat Film, it is important to

maintain a thin-set thickness of 3/8” or less after the tile is embedded, even if the mortar

manufacturer allows for thicker installations. Thicker mortar beds can potentially provide

sufficient moisture to cause some natural stones to warp or crown.

CAUTION:

Flooring materials must be

rated for use with electric floor

warming system.

CAUTION:

Never bang a trowel on the mat

to remove excess mortar from

the trowel. This could damage

the mat.

Loading ...

Loading ...

Loading ...