Loading ...

Loading ...

Loading ...

Troubleshooting

A Class HP Installation a

nd User Instructions R02583

-6 09/15

Page

36

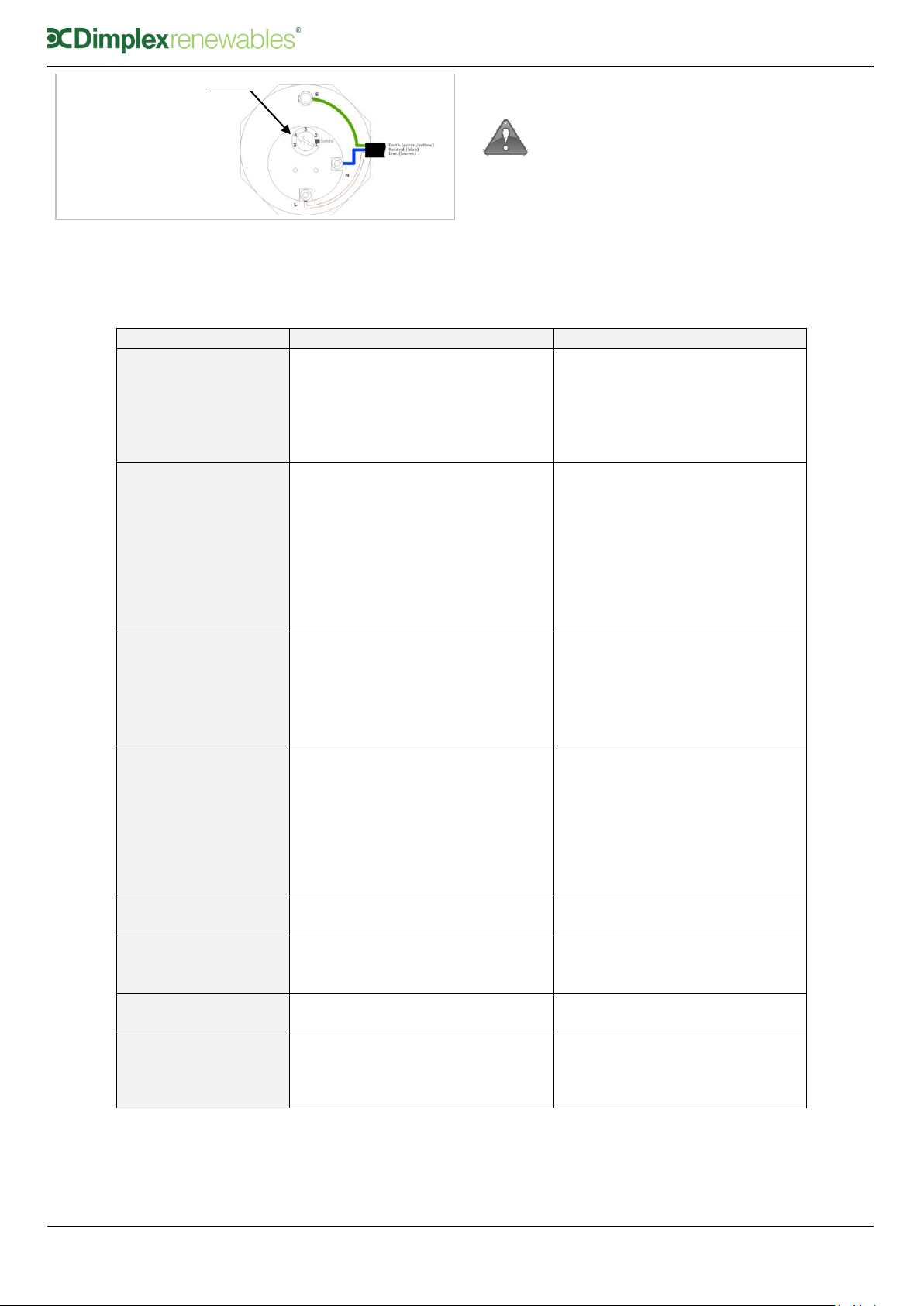

Figure 18: Adjustment Water Temperature Direct

Electric Heating Element

10.4 Maintenance

The maintenance of this appliance

must be carried out by a suitably

qualified person only. It is

recommended to maintain the unit on

an annual basis. Isolate all electrical

supplies from the unit before

commencing work. Danger of

electrical shock! See Section 7.

10.5 Troubleshooting

Fault

Cause

Solution

A No water from

hot water taps

A.1 Stop valve closed

A.2 Strainer blocked

A.3 Pressure reducing valve

fitted against flow

A.1 Open stop valve

A.2 Turn water supply off,

clean strainer and re-

commission

A.3 Re-fit with arrow showing

in direction of flow

B No hot water

B.1 Timer/Programmer not set

correctly

B.2 Auxiliary heating

malfunction

B.3 Direct heating malfunction

B.4 Auxiliary/direct heating

high limit thermostat has

tripped

B.1 Set timer/programmer

correctly

B.2 Consult auxiliary heating

system instructions

B.3 Call for qualified person to

check immersion heater

B.4 Reset limit thermostat(s)

and inform installer

C Intermittent

water

discharge

through

tundish on

warm-up

C.1 Expansion vessel lost

charge

C.1 Check expansion vessel

(see commissioning /

maintenance, top up or

replace

D Continuous

discharge

D.1 Pressure reducing valve not

working

D.2 Pressure relief or T&P valve

not seating correctly

D.3 Malfunction of high limit

thermostat or appliance

D.1 Check pressure after

valve and replace if faulty

D.2 Manually lift valve once or

twice to clear debris,

otherwise replace

D.3 Check function of

thermostats and

appliances

E Leakage from

casing

E.1Compression/threaded

joints not formed correctly

E.1 Re-seal joints with care

F Hot water from

cold tap

F.1 Hot pipe work being routed

adjacent to cold pipe work

F.2 Leaking seal in mixer tap

F.1 Insulate hot pipe work or

re-route

F.2 Replace seals in mixer tap

G Metallic noise

from system

G.1 Pipe work not sufficiently

supported

G.1 Add extra pipe work

fixings

H Humming noise

from system

during re-heat

H.1 Air in system

H.2 Flow rate well in excess of

specification

H.1 Bleed system thoroughly

and re-pressurize

H.2 Reduce pump speed

Table 9: Troubleshooting Guide

Dial to adjust

water temperature

Loading ...

Loading ...

Loading ...