Loading ...

Loading ...

Loading ...

Pre-Installation

A Class HP Installation a

nd User Instructions R02583

-6 09/15

Page

10

CLEANING INSTRUCTIONS: Clean outer

cladding of cylinder with a soft cloth

dampened with warm water only. Do

not use abrasive or aggressive

cleaning materials, such as alcohol or

petroleum based solvents, as this may

damage the surface of the product.

4.3 Cold Water Supply

For satisfactory and safe performance of the

unvented cylinder the water supply must meet

the following criteria:

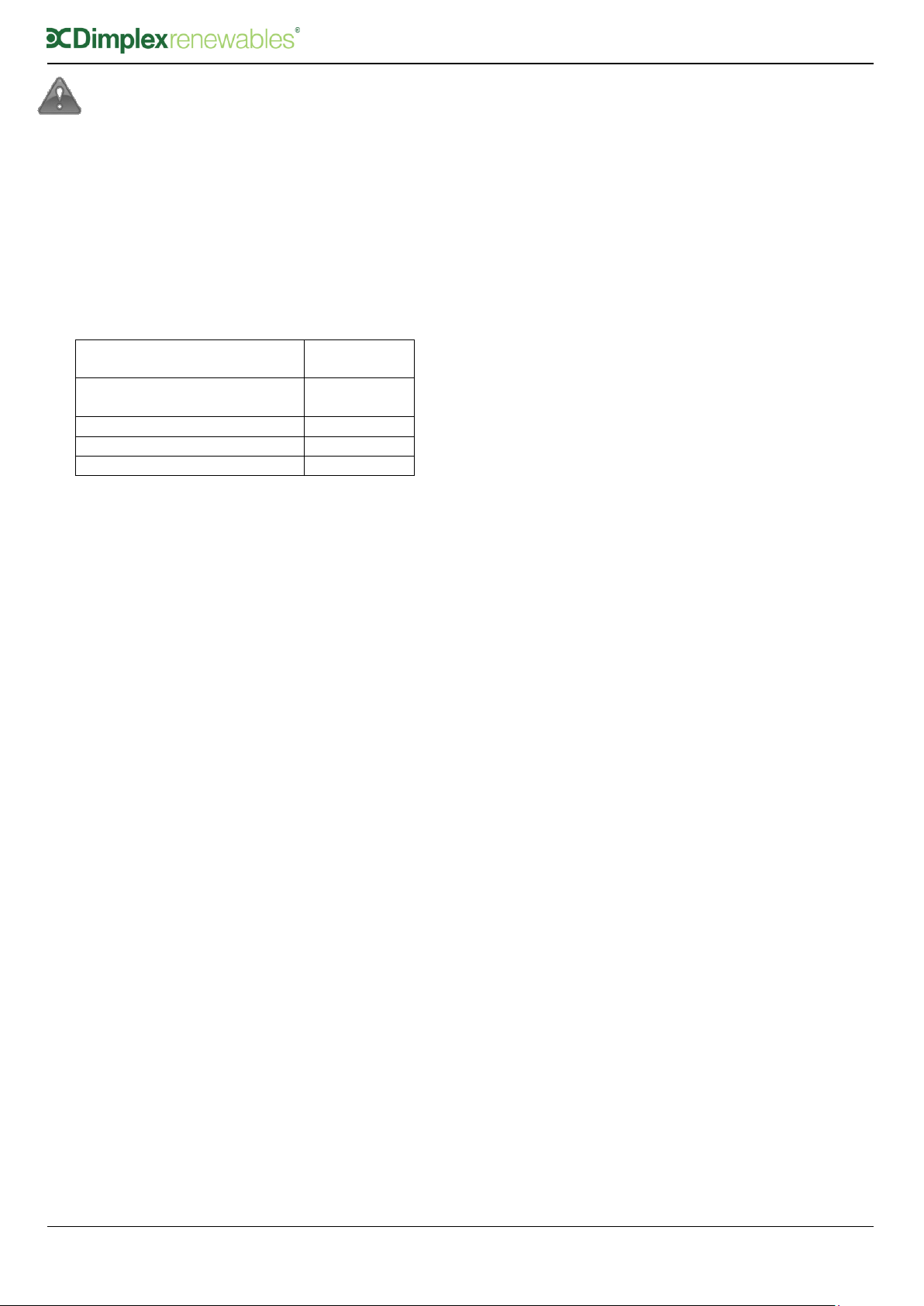

Minimum dynamic

pressure

150 kPa

(1.5 bar)

Maximum inlet supply

pressure

1200 kPa

(12 bar)

Minimum flow rate

15 l/min

Max. chlorine content

250mg/L

Max. water hardness

200mg/L

The following instructions have to be followed

when installing the cold water mains supply to

the cylinder:

The cold water supply to the cylinder must

come directly from the cold water mains

after the mains stop valve to the property.

The cold water inlet pipe work should have

at least an inside diameter of 19mm and

should meet the requirements of the water

regulations for the supply of wholesome

water.

Dimplex recommend an annual maintenance

inspection is carried out on the domestic hot

water cylinder. In hard water areas this should

include inspection of the heat exchanger and

immersion heater, [above 120ppm or 120mg/l].

A local water treatment company should be

able to offer free water quality testing. The

heating elements may require periodic de-

scaling. The installer should do this as part of a

maintenance agreement.

If required, precautions can be taken to

minimise effects of water hardness, i.e.

installation of water conditioner or water

softener. These devices should be installed in

hard water areas where high water storage

temperatures are required, i.e. greater than

60°C storage temperatures, particularly when

water hardness exceeds 200ppm. Should the

water cylinder require de-scaling, this must be

performed by a qualified technician.

4.4 Building Regulation G3 Discharge

Requirements

As part of the requirements of Building

Regulation G3 any discharge from an unvented

system should be conveyed to where it is visible,

but will not cause danger to persons in or about

the building. The tundish and the discharge

pipes should be fitted in accordance with the

requirements of Building Regulation approved

document G3, (England and Wales), Part P of

Northern Ireland and Standard 4.9 of Scotland.

4.4.1 Discharge Pipe D2

The discharge pipe (D2) from the Tundish

should:

“have a vertical section of pipe at least

300mm long below the tundish before any

elbows or bends in the pipework and be

installed with a continuous fall of at least 1

in 200 thereafter.”

The discharge pipe (D2) should be made of:

“metal; or other material that has been

demonstrated to be capable of safely

withstanding temperatures of the water

discharged and is clearly and permanently

marked to identify the product and

performance standard.”

Dimplex strongly recommends the use of metal

pipework only and Dimplex does not take

responsibility for any damage caused from

discharges.

The discharge pipe d2 should be at least one

pipe size larger than the nominal outlet size of

the safety device unless its total equivalent

hydraulic resistance exceeds that of a straight

pipe 9m long, i.e. For discharge pipes between

9m and 18m the equivalent resistance length

should be at least two sizes larger than the

nominal outlet size of the safety device;

between 18 and 27m at least 3 sizes larger,

and so on; bends must be taken into account in

calculating the flow resistance. See Figure 3,

Table 2 and the worked example.

Note: An alternative approach for sizing

discharge pipes would be to follow Annex

D, section D.2 of BS 6700:2006 + A1:2009).

Loading ...

Loading ...

Loading ...