Loading ...

Loading ...

Loading ...

30

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

Gas Connection

This must be in accordance with the relevant standards.

The exible hose (not supplied with the cooker) must be

in accordance with the relevant standards. Hoses may be

purchased at most builders’ merchants.

The gas supply needs to terminate with a down-facing

bayonet.

The connector is located just below the hotplate level at the

rear of the cooker. If in doubt contact your supplier.

The rear cover boxes limit the position of the supply point.

Because the height of the cooker can be adjusted and

each connection is dierent, it is dicult to give precise

dimensions.

Although a 900 mm hose can be used, a 1250 mm hose

will allow slightly more exibility in the positioning of the

bayonet and make moving the cooker easier.

The hose should be tted so that both inlet and outlet

connections are vertical so that the hose hangs downwards in

a ‘U’ shape.

Ideally the hose supply connection should be within the

shaded area (Fig.7-13).

For Natural Gas, the exible hose must be in accordance with

BS 669. For LP Gas, it should be capable of 50 mbar pressure,

70 °C temperature rise, and carry a red stripe, band or label. If

in doubt contact, your supplier.

Screw connect the threaded end of the hose into the gas

inlet.

After completing the gas connection, make sure that the

cooker is gas sound with a pressure test.When checking for

gas leaks do not use washing up liquid – this can corrode. Use

a product specically manufactured for leak detection.

Natural Gas

The adjustable spring loaded gas pressure regulator is preset

to give a nominal pressure of 1 kPa on Natural gas. Connect to

the Rp½ inlet on the underside of the pressure regulator.

Propane

This cooker is supplied ready for use on Natural gas. A

conversion kit for Propane gas is supplied with the cooker –

see the ‘Conversion to Propane Gas’ section.

Pressure Testing

The pressure test point is accessible on the inlet pipe at the

rear. Remove the test nipple screw and t a pressure gauge to

the test point. Turn on and light two of the hotplate burners.

For Natural Gas cookers the pressure should be between

0.95kPa and 1.0kPa.

For Propane X cookers the pressure should be 2.54 kPa.

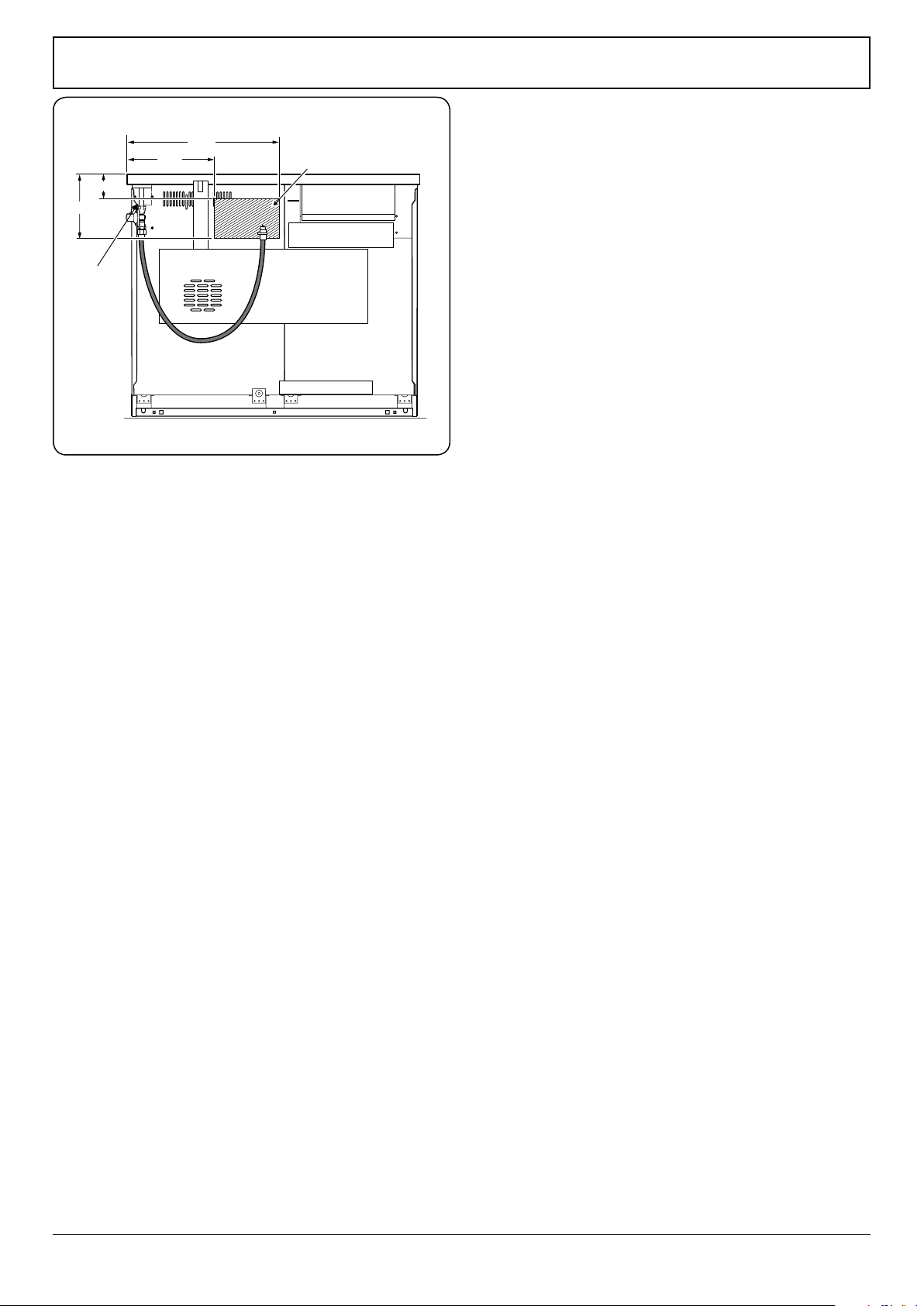

100

350

600

250

Gas inlet

block

Position for gas

supply connector

All dimensions in millimetres

Fig.7-13

Loading ...

Loading ...

Loading ...