Loading ...

Loading ...

Loading ...

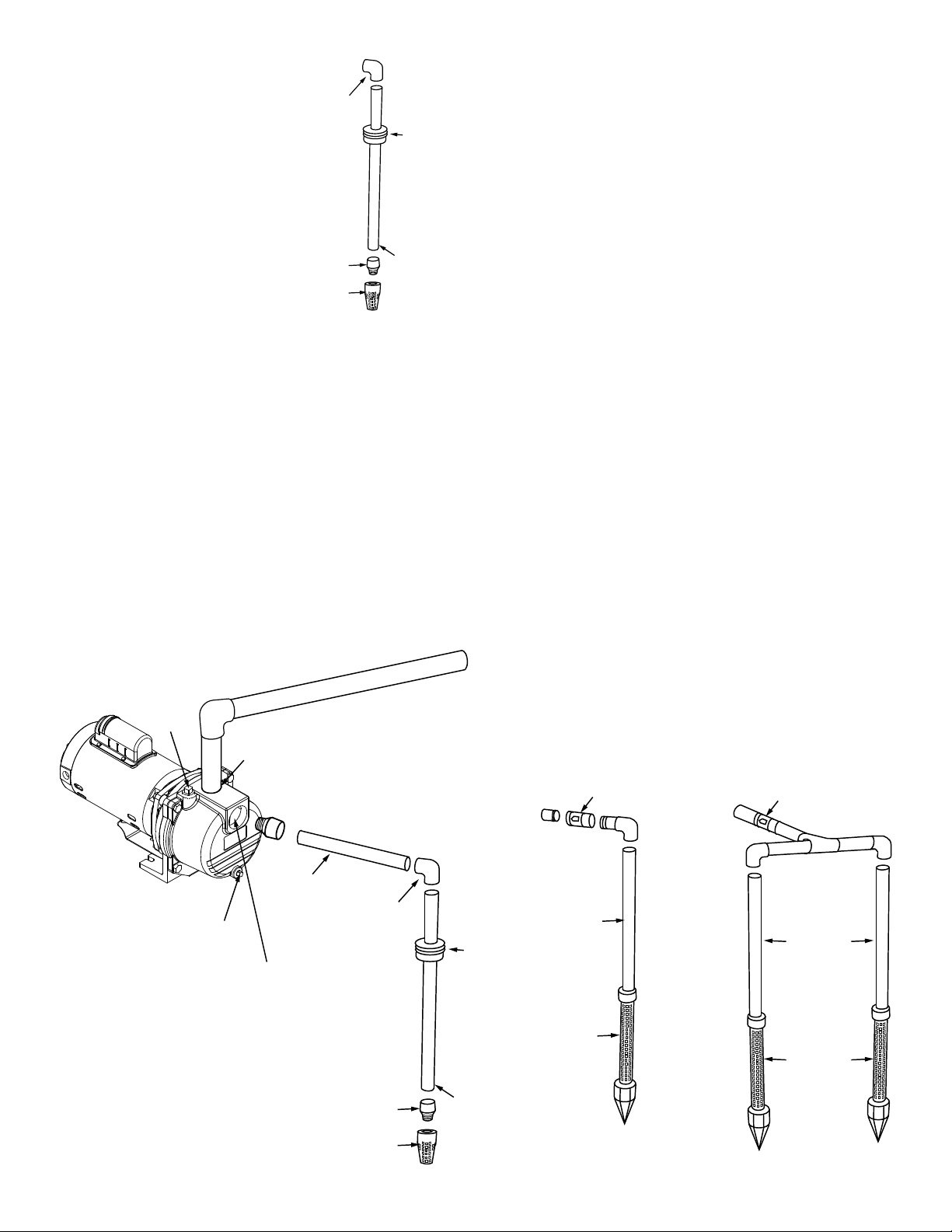

Single Shallow Well (Figure 4)

The single shallow well (Figure 4) is

typically a drilled well with a 4" or 6"

steel or plastic casing running vertically

into the ground. The surface of the water

should not exceed 25 feet in depth.

Connect the foot valve to the first length

of suction pipe and lower into well.

Add pipe sections as needed, securing

them using one of the sealing methods

previously mentioned. The foot valve

should be AT LEAST 5 feet below the

surface of the water to allow for water

draw down. Seal the top of the 4" or 6"

well casing with a well seal to prevent debris from falling into the well.

A. Suction Port Connection (Figure 5)

1. Attach the foot valve or well point to pipe assembly and lower pipe

and foot valve until it is at least five feet below the water level.

If you are using a well, temporarily clamp the pipe to the well casing

to prevent the pipe from sliding into the well. If well is in a 4" or 6"

casing, use a well seal at the surface. Never use a suction pipe size

smaller than the size of the suction port on the pump.

2. Connect the necessary elbows, fittings, check valves, and pipe from

the water to the pump suction port on front of pump. When using

PVC, pre-assemble pipe and fittings to the pump BEFORE applying PVC

cement to ensure proper cuts and inventory. Use PTFE tape on all male

threads, wrapping clockwise (when facing pipe) 1 to 2 layers thick.

Tighten all threaded pipe fittings until snug. DO NOT OVER-TIGHTEN PIPE

AND FITTINGS. Tighten joints hand-tight plus 1/2 turn with pipe wrench.

B. Discharge Port Connections (Figure 6)

1. Thread male adapter or pipe nipple into discharge port on top

of pump. (Use PTFE tape on thread.)

2. Connect pipe between the sprinkler manifold and the pump

discharge. Discharge pipe size should increase with long pipe runs.

Discharge pipe size may equal discharge port size for distances up to

100'. Increase discharge pipe size by one size for distances of 100' to

300'. For 300' to 600', increase pipe size by two sizes. This will reduce

pressure loss caused by friction.

3. Tighten all threaded pipe connections with pipe wrench until snug.

Do not over-tighten.

WELL POINT

INSTALLATION

MULTIPLE WELL

POINT INSTALLATION

2 ADAPTER

2 FOOT VALVE

PRIMING

PORT

1-1/2" NPT DISCHARGE PORT

TO SPRINKLER SYSTEM

DRAIN PLUG

2" NPT SUCTION PORT

2" RIDGED PIPE

ELBOW

WELL SEAL

2 RIDGED PIPE

WELL POINT

2" GALVANIZED PIPE

CHECK VALVE

TO PUMP

TO PUMP

CHECK VALVE

2"

GALVANIZED

PIPE

WELL POINT

Figure 5

Figure 4

RIDGED PVC PIPE

PVC ADAPTER

FOOT VALVE

ELBOW

WELL SEAL

5

Loading ...

Loading ...

Loading ...