Loading ...

Loading ...

Loading ...

540mm Upright Cooker with GAS oven User manual

21

T

T

e

e

s

s

t

t

i

i

n

n

g

g

t

t

h

h

e

e

o

o

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

o

o

f

f

t

t

h

h

e

e

g

g

a

a

s

s

c

c

o

o

o

o

k

k

e

e

r

r

Gas

leakage and operation of the appliance must be tested by the installer before leaving. Check all burner

flames are blue in colour, stable and completely ignite at both high and low flame settings with no appreciable

yellow tipping, carbon deposition, lifting, floating, lighting back or objectionable odour. Test burners

individually and in combination.

When maximum flame appearance is correct, then check the turn-down setting on each burner. If the settings

appear to be incorrect, proceed as follows:

Adjust the bypass screw mounted on the body of each hotplate control cock. This is accessible when

the control knob and the control panel are removed.

Check the ignition on all burners both separately and in combination.

Check the operation of the electrical components, if applicable.

If you are satisfied that the cooker is operating correctly, then turn it off and show the customer how to

use it. Make sure you ask the customer to operate the clock and controls.

Where the data plate is obscured by cabinetry when the cooker is in the installed position, place the supplied

duplicate data plate to a suitable adjacent surface or within the instruction manual for future reference.

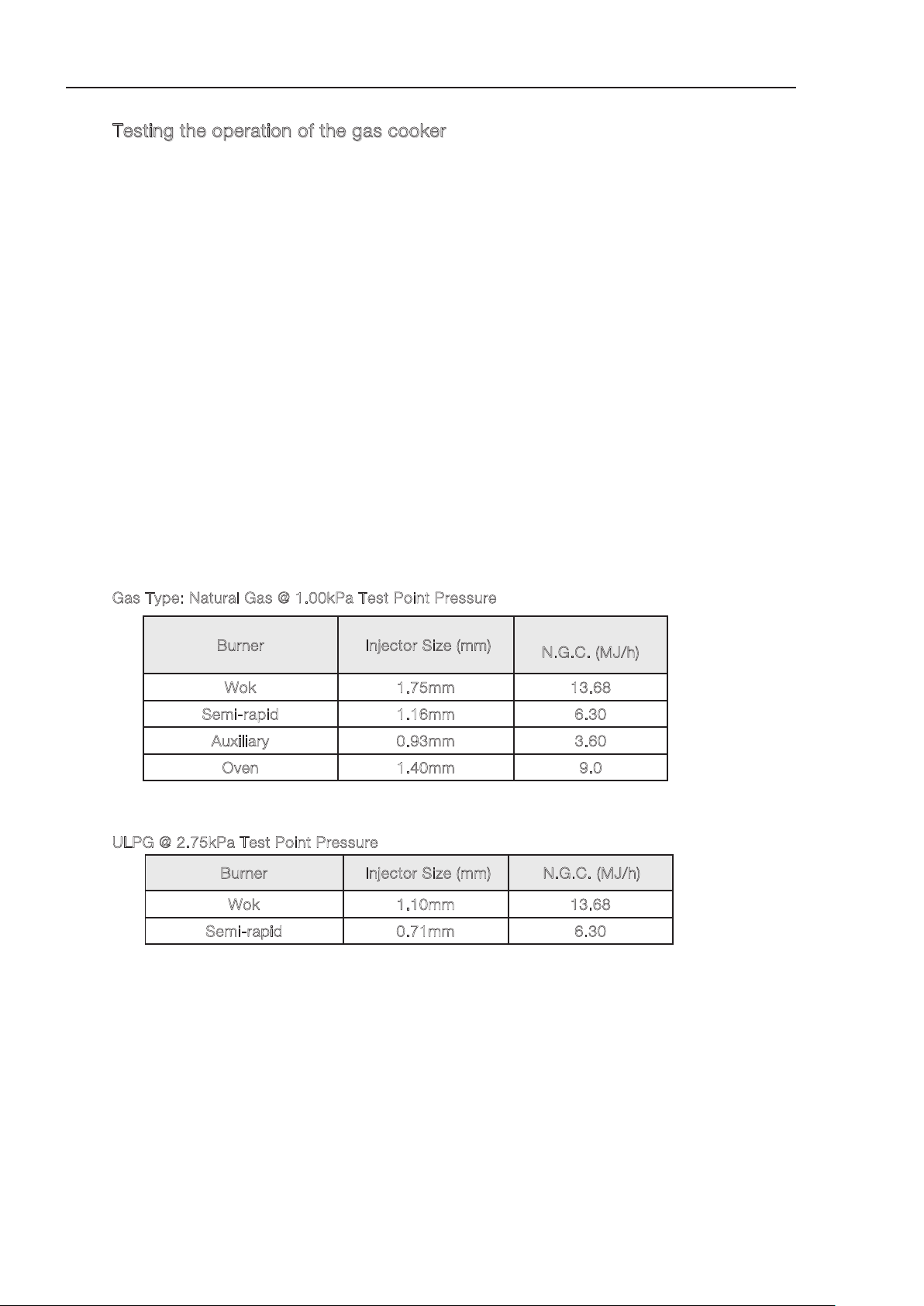

Gas Type: Natural Gas @ 1.00kPa Test Point Pressure

Burner Injector Size (mm)

N.G.C. (MJ/h)

Wok 1.75mm 13.68

Semi-rapid 1.16mm 6.30

Auxiliary 0.93mm 3.60

Oven 1.40mm 9.0

ULPG @ 2.75kPa Test Point Pressure

Burner Injector Size (mm) N.G.C. (MJ/h)

Wok 1.10mm 13.68

Semi-rapid 0.71mm 6.30

Loading ...

Loading ...

Loading ...