Loading ...

Loading ...

Loading ...

10 11ASSEMBLY INSTRUCTIONS FOR TROLLEY

Converting the unit to natural gas

1. Turn off the gas supply valve on the gas cylinder. Ensure

that all gas controls on the BBQ are in the OFF position.

2. Disconnect the hose and regulator from the gas

cylinder and disconnect the gas hose from the barbecue

gas inlet using a 19mm open-ended spanner / wrench.

3. Open hood and remove all cooking plates, grills and

vaporisers from the BBQ.

4. Remove the ‘R’ shaped locking clips that hold each

burner in place and remove all burners from the

barbecue. This needs to be done at the rear of the BBQ.

5. The gas injectors (also known as jets or nozzles) for

each burner are located within deep pockets at the rear

of the BBQ.

6. Remove each gas injector from the end of each jet

holder using a 6mm socket spanner/ wrench, turning

gently in a counter clockwise direction. Be careful not

to block the orifice at the end of the valve where the gas

injector is fitted and do not remove any of the thread

sealing compound from the orifice where the injector is

located.

7. Check the identification mark stamped on the Hex Head

of the injector to confirm that it is the correct size (NG:

2.10mm). Screw correct Jets back into place.

8. When fitting the NG gas injectors to the end of the jet

holder be sure to seat the injector correctly on the

thread before turning it in a clockwise direction until it

is seated firmly in place. Do not over-tighten.

9. Replace all parts into position in the BBQ

10. Refit the burners and secure with the locking clips that

hold each burner is position. Replace the vaporisers,

grills and cooking plates. Note: Check the operation

of each burner- it may be necessary to open the air-

mixture screw (located at the burner venturi) a couple of

turns to get the correct flame.

11. Replace the LPG gas type label with the natural gas

label supplied. 12. Leak test using same procedure for

LPG, as detailed on page 4.

12. Connect the natural gas hose and regulator (where

applicable) to the gas inlet on the barbecue. Tighten

firmly but do not over tighten. Connect gas regulator

to gas source line. Perform leak test using same

procedure as for LPG.

ASSEMBLY AND GAS CONNECTION INSTRUCTIONS FOR SIDE BURNER

ASSEMBLY AND GAS CONNECTION INSTRUCTIONS FOR SIDE BURNER

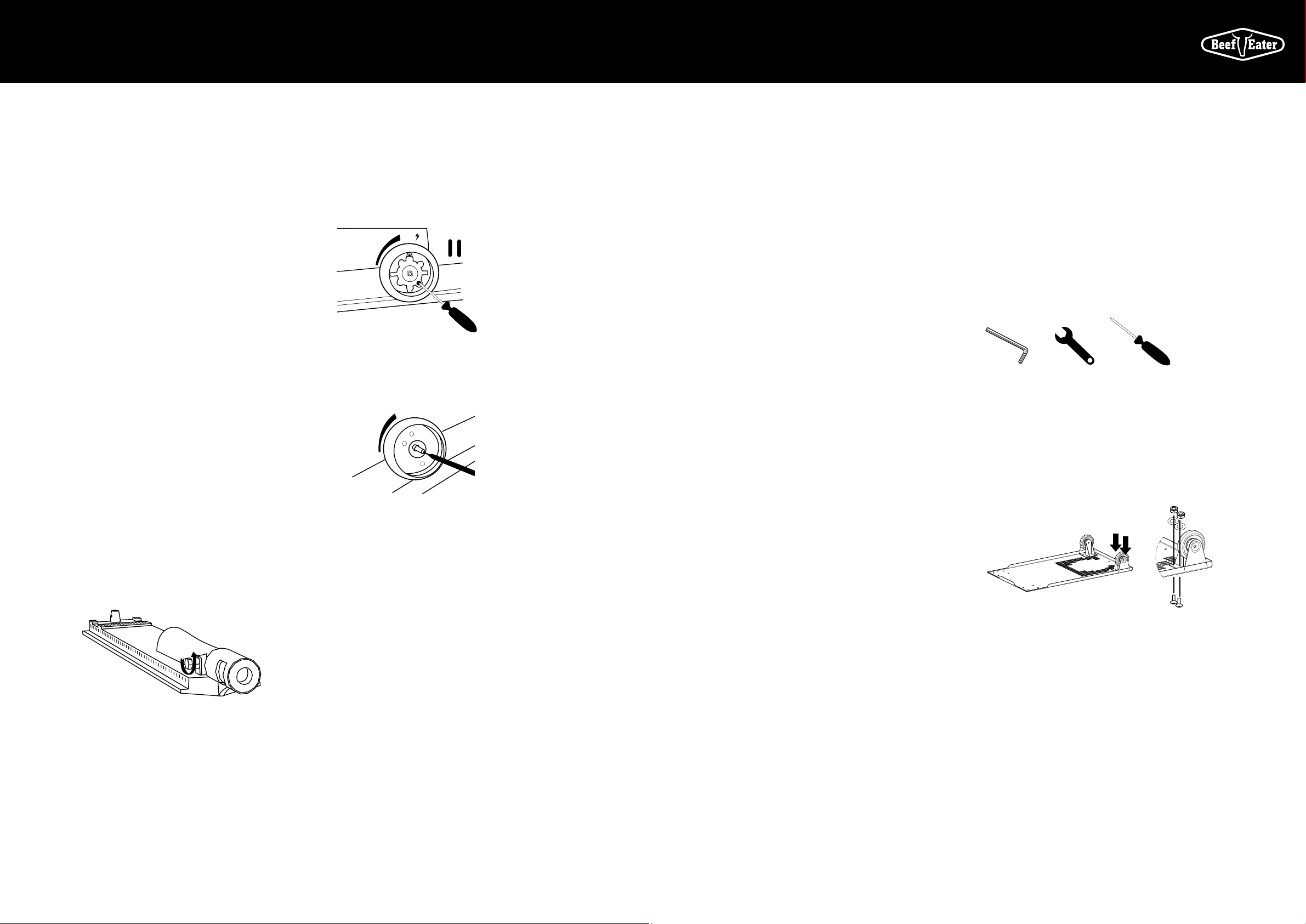

Turn down adjustment

When converting to natural gas the turndown setting will

need to be adjusted to give a satisfactory flame on low

setting on each burner.

• Remove knobs from valve shafts. For ignition valves

the low flame adjustment screw is located on the lower

right hand corner of the front of the valve body.

High

Low

Off

• Using a flat bladed screwdriver, turndown adjustment

screw should be fully inserted and then rotated

• For non-igntion valves the screw is located inside the

knob spindle. Use a 2.5mm wide flat blade screwdriver

full inserted and make a ¾ turn counter clockwise.

Low

• Repeat for other valve.

• Following of the gas and leak testing as per previous

steps, light both burners and set to high.

• One burner at a time turn the valve shaft to lowest

setting, observe the flame to ensure a small steady

flame in achieved.

• Turn off burners and replace control knobs, ensuring

the knob is in the correct orientation when valve is in

“OFF” position.

Fixed Installation - Portable LP Gas/Propane.

BeefEater LPG/propane barbecues are designed to operate

at 2.75Kpa (11”WC).

Connect the gas supply line to the barbecue inlet located on

the right side of the appliance using either hard plumbing,

or a flexible hose connected to a bayonet point, also known

as a quick connect fitting.Refer to AS 5601 or your local

installation code for pipe sizing details.Secure all joints

spanner (wrench) tight but do not over-tighten.

Aeration Screw Adjustment

ASSEMBLY INSTRUCTIONS

FOR TROLLEY

Test gas pressure by removing the last burner from the

left hand side of the barbecue and attaching a hose and

pressure gauge to the end of the gas valve.Turn on 2

burners and check the pressure.Inlet pressure should be

11.0” WC or 2.75 kPa.

Fixed Installation - Natural Gas

(Natural Gas installation should be carried out by a qualified

gas fitter).

BeefEater Natural Gas barbecues are designed as low-

pressure appliances (4.0” WC, 1.00KPa).

Fit the natural gas regulator supplied directly to the

barbecue inlet located on the right side of the appliance

using either hard plumbing, or a flexible hose connected to

a bayonet point, also known as a quick connect fitting.Refer

to AS 5601 or your local installation code for pipe sizing

details.Secure all joints spanner (wrench) tight but do not

over-tighten.

Test gas pressure by removing the last burner from the

left hand side of the barbecue and attaching a hose and

pressure gauge to the end of the gas valve.Turn on 2

burners and check the pressure.Inlet pressure should be

4.0” WC or 1.00 kPa.

Australia only (applies to all gas types) : Where a mobile

appliance is to be connected to a fixed gas supply via a

flexible hose connection, a retaining tether of adequate

strength shall be fixed to the appliance and be suitable to

be fixed to the wall within 50mm of each connection

point. The length of the tether shall not exceed 80% of the

length of the hose assembly. In this way, if the barbecue

is accidentally moved, the chain stops the barbecue from

stretching the hose.

The barbecue appliance must be isolated from the gas

supply piping system by closing its manual shutoff valve

during any pressure testing of the gas supply piping system.

Before You Start

Note the tools you will need before you begin.

Check for damaged or missing parts, and consult your

retailer if necessary.

Many components and panels are covered with a protective

sheet of plastic. You will need to remove this plastic covering

from all surfaces, especially where two panels join. It is

a good idea to leave some plastic on the panels during

assembly to protect the stainless steel during the assembly

process. Ensure however that all plastic covering is removed

on completion.

Always assemble on a clean, smooth, flat working surface

that will not scratch the surface of the stainless steel.

Allen Key Adjustable

spanner/

wrench

Phillips head

screwdriver

1) Fit The Fixed Castors

Fit the fixed castors into the holes in the bottom of the base.

At this step, use only two Allen head screws, washers and

nuts for each castor in the positions shown. The two outside

screws will be put on in step 3.

Spanner/wrench tighten immediately.

Note lip

ends here

Loading ...

Loading ...

Loading ...