Loading ...

Loading ...

Loading ...

12 • Residen al Standard Gas Water Heater Use and Care Guide

GETTING STARTED

12 • Residen al Standard Gas Water Heater Use and Care Guide

GETTING STARTED

• The vent pipe must be fi rmly at-

tached and sealed to prevent it

from falling out.

• To aid in removing the vent pipe, a

thimble or slip joint may be used.

• The vent pipe must not extend

beyond the inner edge of the

chimney as it may restrict the

space between it and the opposite

wall of the chimney.

Do not terminate the vent pipe in a

chimney that has not been cer fi ed

for this purpose. Some local codes may

prohibit the termina on of vent con-

nectors in a masonry chimney.

Common (combined) ven ng is allow-

able with ver cal Type B vent systems

and lined masonry chimneys as long

as proper dra for the water heater

is established under all condi ons of

opera on. Do not common vent this

water heater with any power vented

appliance.

Ver cal Termina on

NOTICE: The gas vent must be termi-

nated in a ver cal posi on to facilitate

the removal of exhaust gases.

Ver cal exhaust vents must terminate

with a listed cap or other roof assem-

bly and be installed according to their

manufacturer’s instruc ons. An unused

chimney fl ue or masonry enclosure

may be used as a passageway for the

installa on of vent pipe. Do not com-

mon vent this water heater with any

power vented appliance. The follow-

ing fi gures are examples of vent pipe

system installa ons and may or may

not be suitable for your specifi c appli-

ca on. Consult the “Na onal Fuel Gas

Code”, NFPA 54, ANSI Z223.1-current

edi on and local codes.

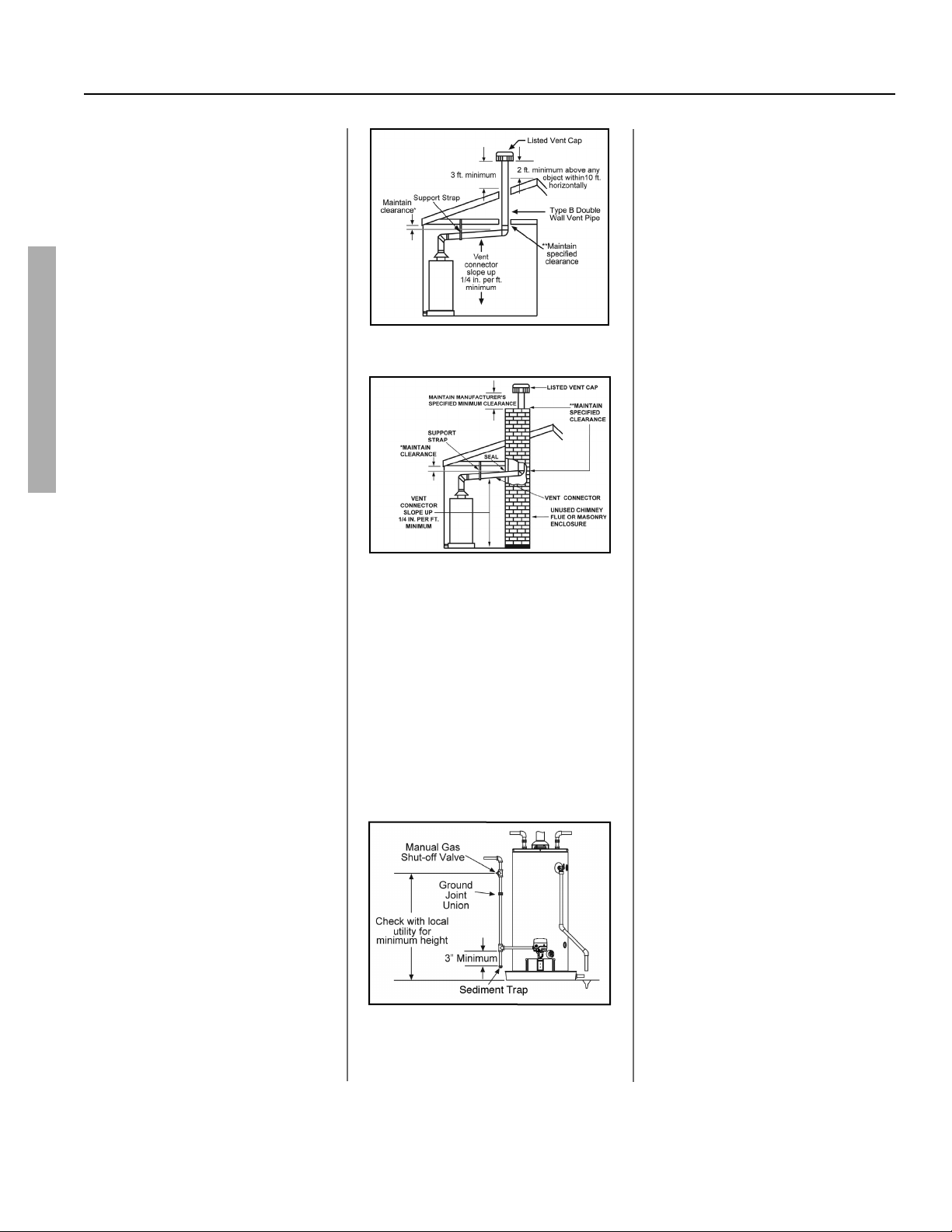

Figure 8 - Vertical gas vent system with type B

double wall vent pipe

Figure 9 - Venting through a chimney with type

B double wall vent pipe

Gas Piping

Gas piping must be installed accord-

ing to local and state codes or, in the

absence of local and state codes,

the “Na onal Fuel Gas Code”, ANSI

Z223.1(NFPA 54)-current edi on.

NOTICE: When installing gas piping,

apply pipe joint compound or Tefl on®

tape approved for fuel gases.

Figure 10 - Gas Piping

1. Install a readily accessible manual

shut-off valve in the gas supply line

as recommended by the local u l-

ity. Know the loca on of this valve

and how to turn off the gas to this

unit.

2. Install a Sediment Trap as shown

in the Gas Piping fi gure below. The

Sediment Trap must be no less than

three inches long for the accumula-

on of dirt, foreign material, and

water droplets.

3. Install a ground joint union be-

tween the gas control valve and

the manual gas shut-off valve. This

is to allow easy removal of the gas

control valve.

4. Turn the gas supply on and check

for leaks. Use a small, so -bristled

brush to apply a hand dishwash-

ing soap and water mixture (1

part soap to 15 parts water) or

children’s soap bubbles to all con-

nec on points of the gas piping.

Saturate all the connec ons and

check for gas leaks (which will ap-

pear as small bubbles). If any leaks

are detected, ghten the appropri-

ate connec on(s) and re-check.

Gas Pressure

NOTICE: When tes ng gas pipes with

a test pressure of more than ½ psi (3.5

kPa), disconnect the gas line at the

manual shut off valve and cap the gas

line. Do not subject the water heater’s

gas control valve or manual shut off

valve to more than ½ psi (3.5 kPa)

pressure for any reason. If you are

pressure tes ng the gas line with test

pressure of ½ psi (3.5 kPa) or less, you

may isolate the water heater from the

gas line by closing the manual shut off

valve.

Loading ...

Loading ...

Loading ...