Loading ...

Loading ...

Loading ...

M (E2) 04/2019 page 52/71

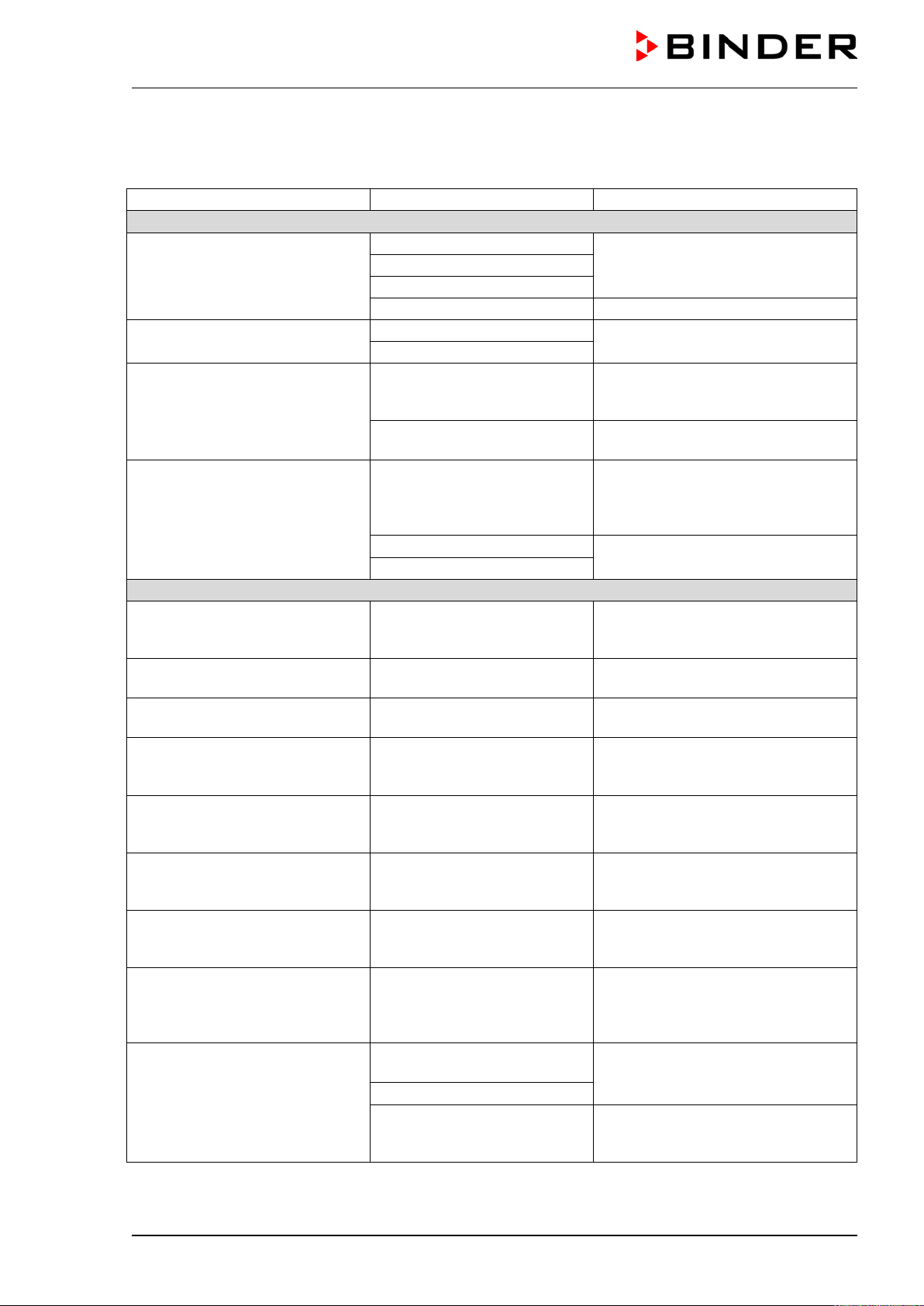

14. Troubleshooting

Fault description

Possible cause

Required measures

Heating

Chamber heating permanently,

set-point not maintained.

Controller defective.

Contact BINDER service.

Pt 100 sensor defective.

Semiconductor relay defective.

Controller not adjusted.

Calibrate and adjust controller.

Chamber doesn’t heat up.

Heating element defective.

Contact BINDER service.

Semiconductor relay defective

Chamber doesn’t heat up when

turned on.

Safety device class 2 responds.

Limit temperature reached.

Safety device class 2 (chap.

10.1) set too low.

Let the chamber cool down and hit

RESET button (3b). If appropriate,

select suitable limit value.

Safety controller (chap. 10.1)

defective.

Contact BINDER service.

Safety device class 3.1 (option)

responds.

Limit temperature reached.

Check setting of temperature set-

point and of safety device class 3.1.

If appropriate, select suitable limit

value.

Controller defective.

Contact BINDER service.

Safety device defective.

Controller

No entries to controller keypad

possible. Notification “KEY

LOCK” is displayed

Keyboard locking (option)

activated.

Unlock keyboard locking (chap.

11.10).

No access to menu “User set-

tings”“.

User code incorrect. Contact BINDER service.

Wrong temperature alarms, dis-

turbance of temperature accuracy

Temperature unit changed to

°F.

Set temperature unit to °C (chap.

6.4).

Chart recorder function: meas-

ured-value memory cleared, in-

formation lost.

New setting of storage rate.

Change the storage rate ONLY if the

previously registered data are no

longer required (chap. 7).

Controller does not attain set-

points entered in Manual Mode.

Button EXIT or AUTOMATIC

has been hit: Chamber is in

Idle Mode.

Change to Manual Mode (chap. 8).

Controller does not attain pro-

gram set-points.

Button EXIT or AUTOMATIC

has been hit: Chamber is in

Idle Mode.

Start the program again (chap. 9.7).

Program duration longer than

programmed.

Tolerances have been pro-

grammed.

For rapid transition phases, do NOT

program tolerance limits in order to

allow maximum heating, speed.

Program stops one section too

early.

Program line is incomplete.

When programming, define the end

value of the desired cycle by adding

an additional section with a section

time of at least one second.

Display flashing:

1999 or -1999 or 9999.

Sensor rupture between sen-

sor and controller

Contact BINDER service.

Short-circuit.

Initialization problem due to

turning on the chamber too

early.

Observe a delay time of approx. 30s

between turning the chamber Off

and On again.

Loading ...

Loading ...

Loading ...