Loading ...

Loading ...

Loading ...

GasSupply Pressure Testing

A 1/8" NPT minimum plugged tapping, accessible for gauge

testing, must be installed immediately upstream of the gas supply

connection to the dryer.

For ease of installation, operation, and servicing adequate space

should be provided around the dryer.

The dryer must be isolated from the gas supply piping system

by closing the equipment shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal

to or less than 1/2 psi (3,45 kPa).

Test all connections by brushing on an approved non-corrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

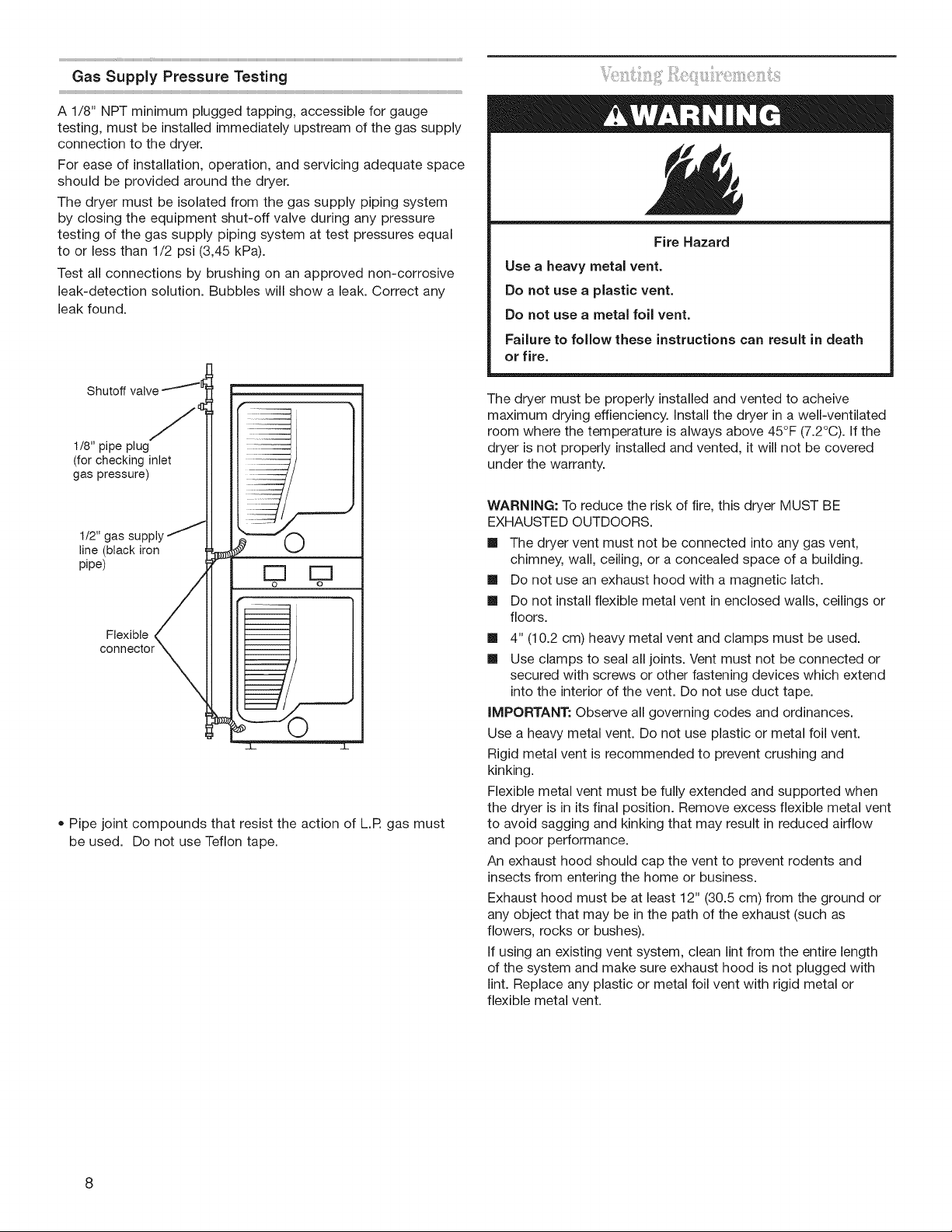

Shutoff valve

1/8" pipe plug

(for checking inlet

gas pressure)

1/2" gas supply

line (black iron

pipe)

Flexible

• Pipe joint compounds that resist the action of L.R gas must

be used. Do not use Teflon tape.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

The dryer must be properly installed and vented to acheive

maximum drying effienciency. Install the dryer in a well-ventilated

room where the temperature is always above 45°F (7.2°C). If the

dryer is not properly installed and vented, it will not be covered

under the warranty.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

[] The dryer vent must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building.

[] Do not use an exhaust hood with a magnetic latch.

[] Do not install flexible metal vent in enclosed walls, ceilings or

floors.

[] 4" (10.2 cm) heavy metal vent and clamps must be used.

[] Use clamps to seal all joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 12" (30.5 cm) from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Loading ...

Loading ...

Loading ...