Loading ...

Loading ...

Loading ...

USER MANUALPG 24

INSTALLING THE GAS

COOKER

Unpacking

Do not fit the burner crowns, burner caps and trivets until after the

cooker has been installed.

Checking gas pressures

Before installation check that the cooker is suitable for the gas supply.

To do this check the gas type on the carton sticker or on the data

plate behind the bottom of the oven door. If the cooker is required to

be used with LPG, the supplied conversion kit must be used.

The following shows the supply and operating pressures for various

gas supplies.

Operate pressure at appliance test point:

1.00 KPa (Natural gas); N2.75 KPa (Universal LPG gas)

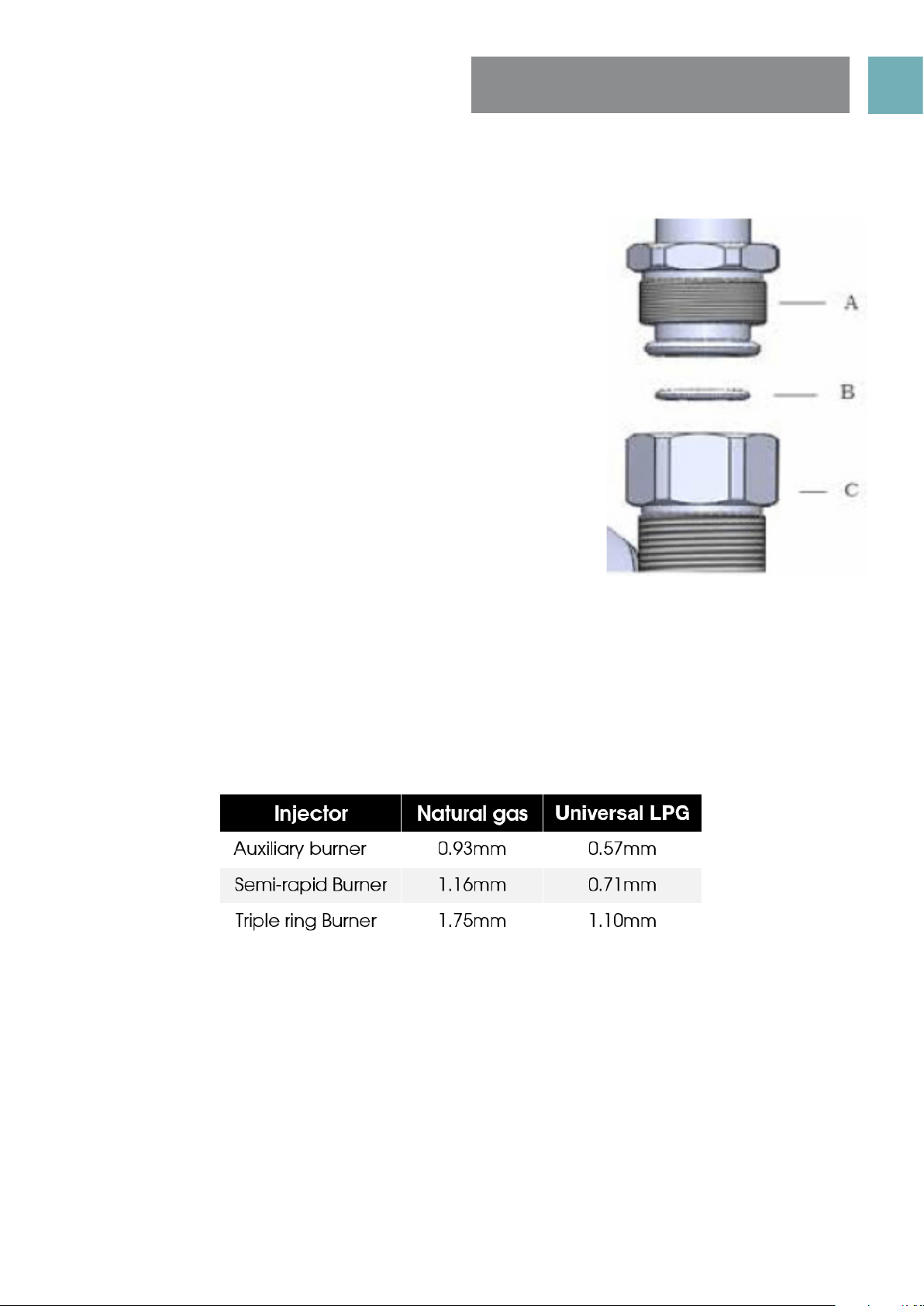

The following table shows the injector sizes for each burner.

Connection to the gas supply

• The gas Connection must be made in accordance with the local standards.

• When installing, fit a safety tap at the end of the pipeline. The appliance leaves the factory tested and

set for the type of gas indicated on the plate inside the bottom guard, close to the gas connection

pipe. Make sure that the type of gas to be supplied to the appliance is the same as that shown on the

plate.

• For maximum efficiency and minimum consumption, make sure that the gas supply pressure complies

with the values shown in the gas used is different from that specified (or variable).a suitable pressure

regulator must be installed on the supply pipeline.

Procedure

Make the connection to the gas system using a rigid metal pipe and regulation unions, or with a stainless

steel hose complying with the local standard. If metal hoses are used, take care that they do not come into

contact with mobile parts and are not crushed.

When making the connection, take care not to apply stresses of any kind to the appliance.

Read these points before connecting to the gas supply;

• The gas connection point is a 1/2” BSP external thread located at the rear of the appliance as shown in

the Rear View.

• A regulator is supplied for natural gas appliances which must be fitted in the supply line to the

appliance. For LPG the supplied brass Test Point Adapter / Fitting must be fitted to the supply line.

• It is recommended to fit the regulator or test point fitting to the appliance connection point, then fit

either hard piping or a flexible connection from the regulator or test point fitting to consumer hard

piping. Ensure installation allows withdrawal of appliance. For flexible hose installation AS/NZS 5601.1

clauses 5.9 and 6.10.1.9 must be followed.

Loading ...

Loading ...

Loading ...