Loading ...

Loading ...

Loading ...

8

3 Installation (cont'd)

3.3 Installing the Registers, Ductwork and Hoods

3.3.1 Registers

Refer to applicable building codes to plan where the stale air exhaust registers and fresh air distribution registers should be

installed. Below are some general recommendations.

Stale air exhaust registers:

• Install the stale air exhaust registers where the contaminants are produced: bathroom (up to 2), kitchen, living room, etc.

Position the registers as far from the stairway as possible and in such a way that the air circulates in all the lived-in spaces in

the house.

• If a register is installed in the kitchen, it must be located at least 4 feet away from the cooking applicances.

• Install the registers on an interior wall, 6 to 12 inches below the ceiling OR in the ceiling.

Fresh air distribution registers (Option 2 in 3.2.1):

• Install the fresh air distribution registers in bedrooms, dining rooms, living rooms and basement, if applicable.

• Keep in mind that the fresh air registers must be located as far as possible from the ERV stale air registers.

• Install the registers on an interior wall, 6 to 12 inches below the ceiling OR in the ceiling.

• If a register must be oor installed, direct the air ow up the wall.

WARNING

Never install a stale air exhaust register in a closed room where a combustion device operates, such as a gas

furnace, a gas water heater or a replace.

!

3.3.2 Ductwork

• All units ports should be connected to 6” ducts, but can be connected to larger ducts using an appropriate transition.

• If you have to connect rigid ducts to the unit, use a short length (approximately 6”) of exible duct to avoid transmission of

vibrations. Use a tie wrap and foil tape to connect the exible duct to the port and to the rigid duct.

• Never use screws to connect rigid ducting to the ports.

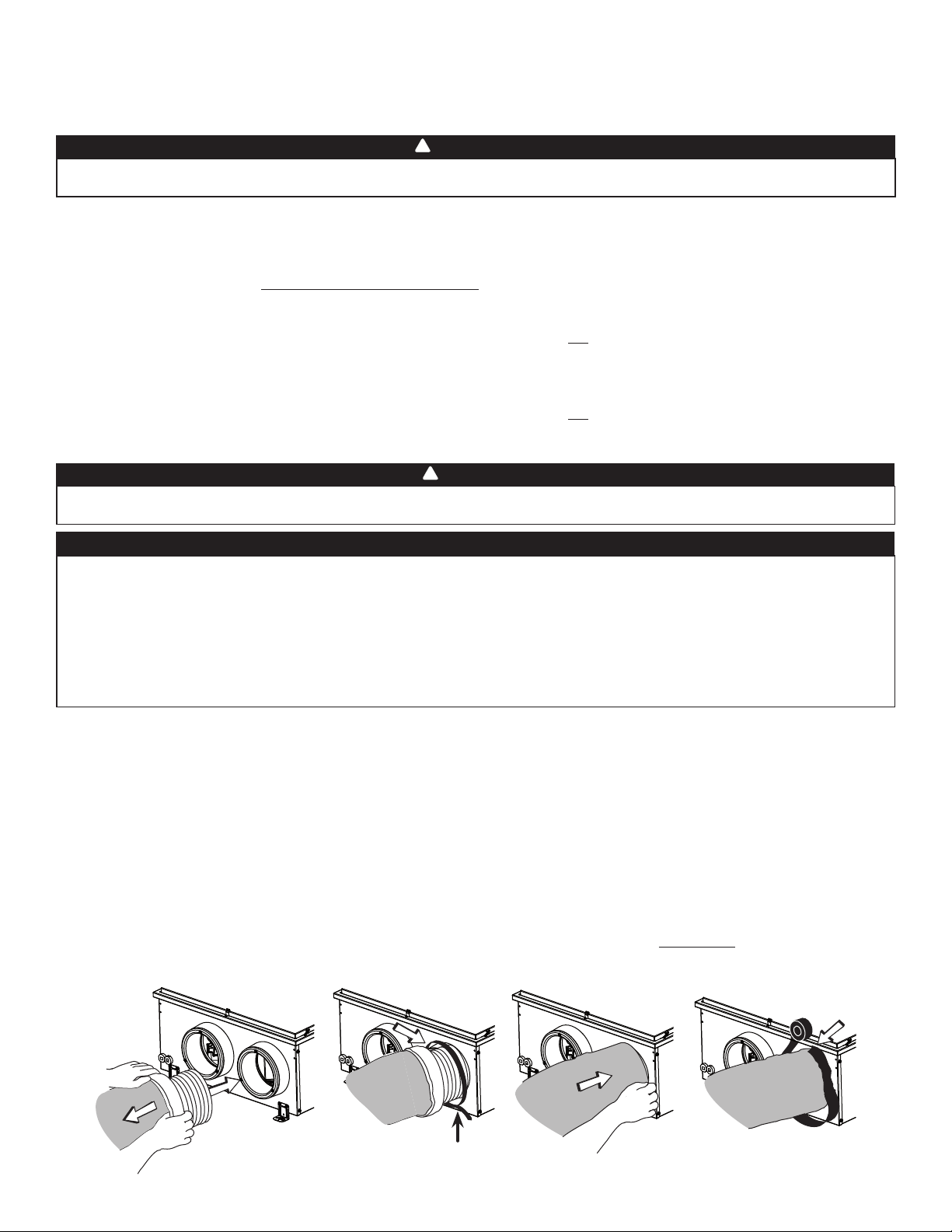

Connecting insulated exible ducts to the ports:

1. Pull back the insulation to expose the exible duct.

2. Attach the exible duct to the port using a tie wrap; ensure tie wrap is tighten to its maximum strength.

3. Pull the insulation over the joint, then pull the vapor barrier (shaded part in illustrations below) over the insulation. Make sure

that the vapor barrier does not tear due to manipulation to avoid condensation within the ducts.

4. Apply foil tape to the joint, making an airtight seal. Avoid compressing the insulation when pulling the tape tightly around

the joint. Compressed insulation loses its R value and causes water dripping in cold climates due to condensation on the

exterior surface of the duct.

NOTE: If sealant mastic has to be used over the foil tape as an extra sealing layer, use water based mastic to ensure material

compatibility with the port.

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding laws and

safety regulations. Please refer to your local building code.

!

CAUTION

If ducts have to go through an unconditioned space (e.g.: attic), always use insulated ducts to prevent condensation

formation inside and outside ducts, which could cause material damage and/or mold growth. Moreover, in zone B, if

fresh air to building duct and/or stale air from building duct goes/go through an unconditioned space, these ducts must

be buried with a minimum of R20 insulation in order to prevent heat recovery performance reduction and cooling of

the distributed fresh air to the living areas during winter operation. Also, the unit must be set to operate continuously

in cold conditions (below 50°F) if these ducts have to go through an unconditioned space in zones A and B. Continuous

air movement inside ducts will prevent condensation formation. The unit can be stopped temporarily for maintenance

and/or repair purposes in such conditions.

VJ0134

TIGHTEN TIE WRAP TO ITS

MAXIMUM STRENGTH!

Loading ...

Loading ...

Loading ...