Loading ...

Loading ...

Loading ...

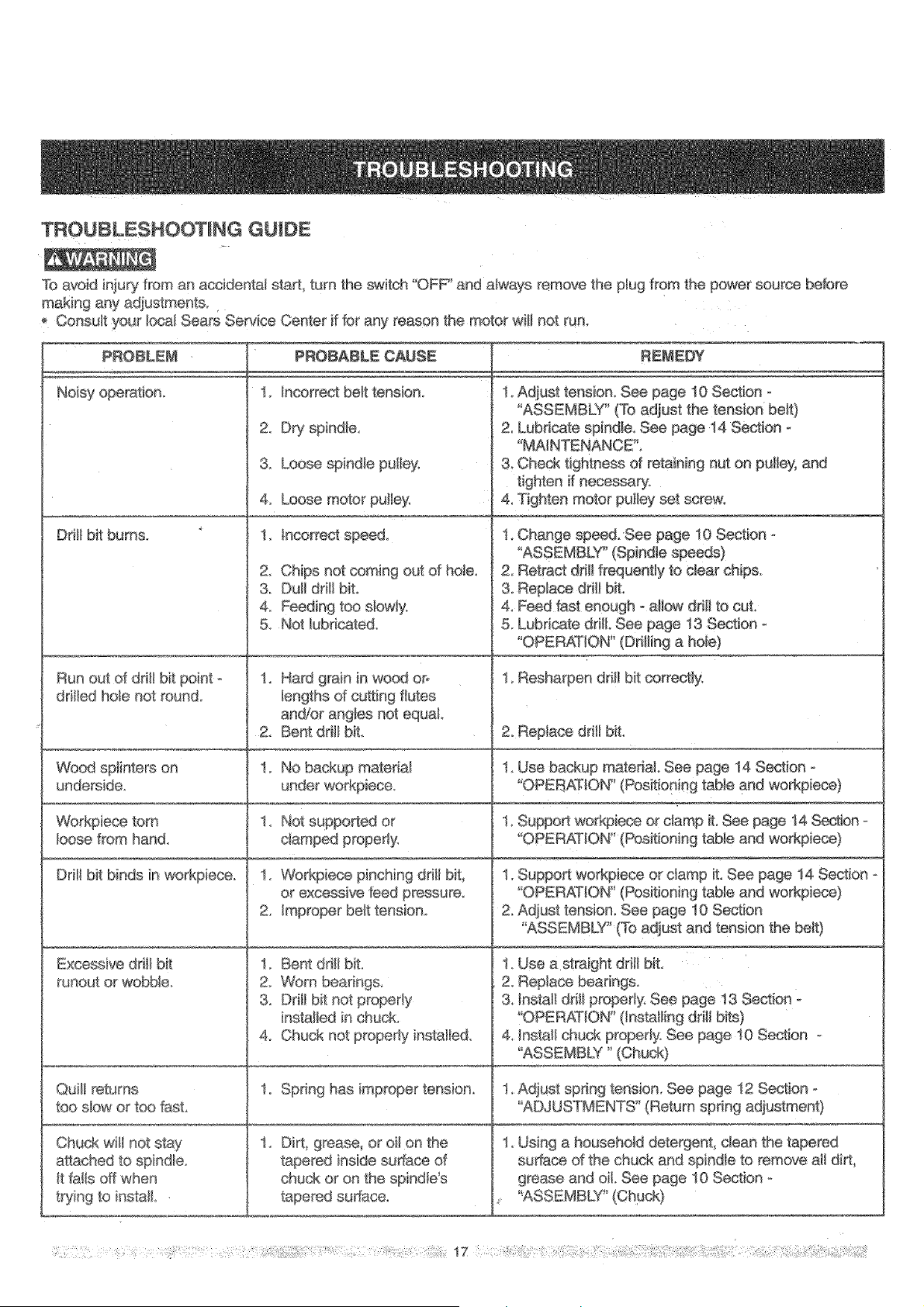

TROUBLESHOOT# G GUIDE

To avoid injury from an a_idental staA, turn the switch "OFF' and a_ways remove the ptug from the power source before

making any ad}ustment&

ConsuJt your bcal Sears Service Center if for any reason the motor wil_not run_

DdH bit burns.

PROBLEM

dritbd hob not round

Wo_ sp_inters on

underside,

/_se from hand.

Drill bit bfnds in workpiece

Excessive ddH bit

runout or wobble

Quill returns

too s_owor too fasL

REMEDY

Chuck will not stay

a_ached to spindle

It falb off when

tq/ing to install..

PROBABLE CAUSE

t_ hc_rrect be_ttension.

2 Dry spindle,

& Loose spindJe puJtey.

4o Loose motor pu_Jey.

1. hcorrect speed.

2. Chips not coming out d ho{e,

3. Dull driil bit.

4. Feeding too slowJy.

5. Not _ubdcated,

Hard grain in wood oro

lengths d cu_ing flutes

2. Bent ddll b_[

1. No backup material

t, Not supported or

I. Workpiece pinching drill bit,

or excessive feed pressure,

2_ _mproper belt tension,

1_ Bent drill bit.

2. Worn bearing&

3. Drill bit not property

installed in chuck.

4. Chuck not propedy insta_bd.

t. Spring has improper tension

Dirt_ grease, or oil on the

tapered inside sudace d

chuck or on the spindWs

tapered sudace,

I Adjust tension. See page I0 Section -

"ASSEMBLY" (To adjust the tension bett)

2, Lubricate spindle, See page 14 Section -

"MA_NTBNANCE'L

3, Check tightness d retaining nut on pulley, and

tighten if necessaK>_

4. Tighten motor pulley set screw,

1_Change speed.See page 10 Section

"ASSEMBLY" (Spindle speeds)

2, Retract drift frequently to c_earchips.

3, Replace drill bit.

4, Feed fast enough oalbw dfilJ to cut,

5_Lubricate dritL See page 13 Section

"OPERATION '_(Drilling a hole)

1, Resharpen drill bit correctly.

2. Replace drill bk,

t, Use backup matedaL See page 14 Section

"OP£BATION" (Posit!oning table and workpiece)

1. Suppo£ workpiece or clamp it. See page 14 S_tion

"OPERATION" (Positioning table and workpiece)

1. Support workpiece or damp it. See page 14 Section -

'gPERATION" (Positioning table and workpiece)

2, Adjust tension. See page 10 Section

_ASSEMBL¥" (Tb adjust and tension the belt)

1. Use a straight ddtl bR,

2. Replace bearing&

& hsta_t drill proper_y, See page 18 Section -

"OPERATION" (installing drill bits)

4, Ins_l chuck proper_y.See page 10 Section -

I, Adjust spring tension_ See page 12 Section -

_%DJUSTMENTS" (Return spring adjustment)

1_Using a household detergent, clean the tapered

surface d the chuck and spindb to remove all dirt,

grease and oil See page 10 Section

Loading ...

Loading ...

Loading ...