Loading ...

Loading ...

Loading ...

ADJUSTMENTS

NOTE: All necessary adjustments for the proper functioning

of your drHJpress nave been made at the factory, Phase

do net modify them. However. because of normal wear

and tear on your tool, some readjustments may be

necessary,

Always unp{ug your tool from the Power source before

any adjustment°

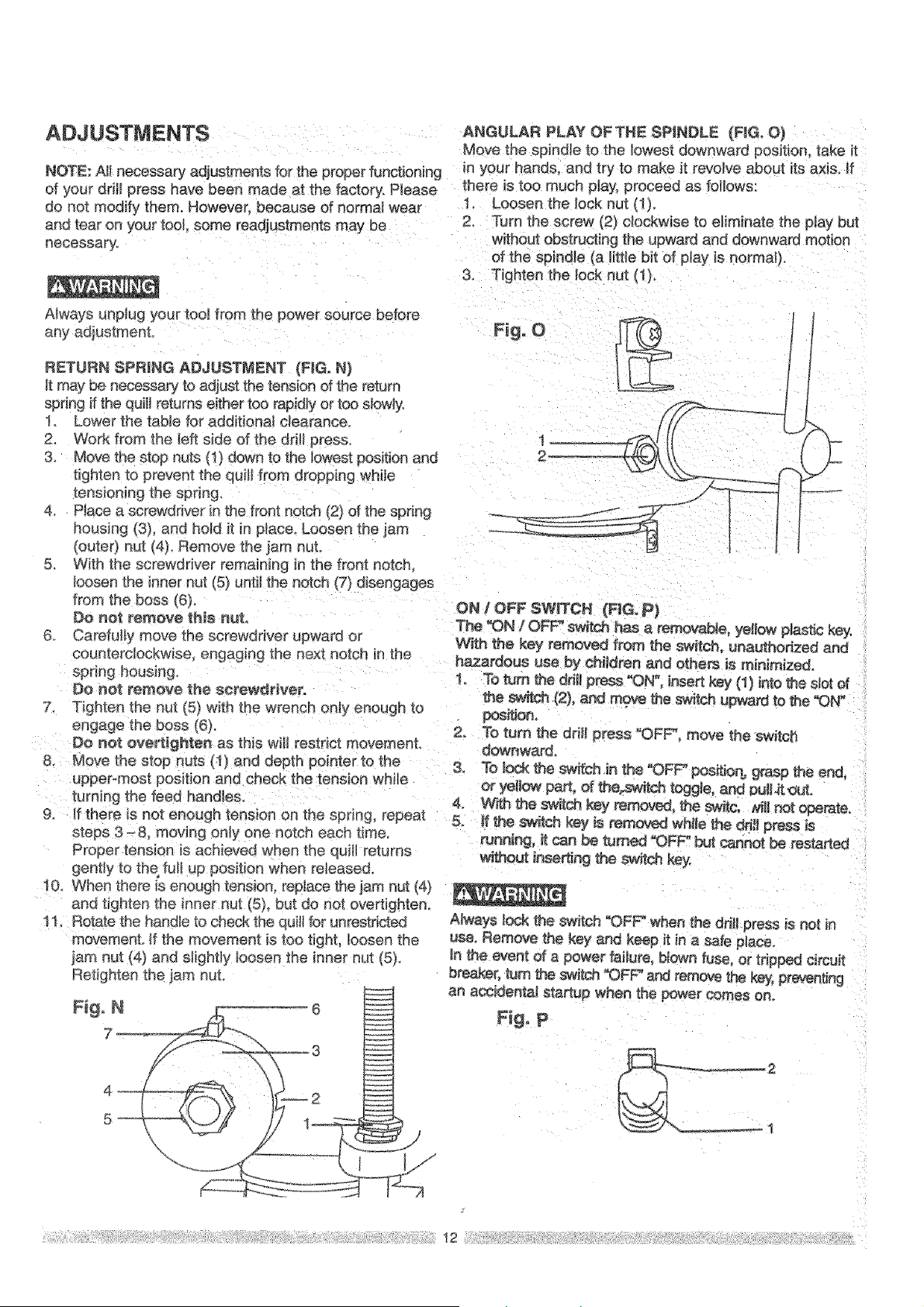

RETURN SPRING ADJUSTMENT {FIG. N)

It may _ necessary to adjust the tension of the re[urn

spdng if the quill returns either too rapidly or too slowly,

1. Lower the tabb for additional ciearanceo

2. Work from the teft side of the drill press,

3. Move the stop nuts (1) 4own to the k)west position and

tighten to prevent the quill from dropping wh{le

tensioning the spring_

4. Place a screwdriver in the front notch (2) of the spring

housing (3), and hold it in place. Loosen the jam

(outer) nut (4) Remove the/am nuL

5. With the screwdriver remaining in the front notch

bosen the inner nut (5) until the notch (7) disengages

from the boss (6}.

Do not remove this nut,

6 Carefully move the screwdriver upward or

coume rclockwise engaging the next notch in the

Do nol_ remove the screwdriver°

7 Tighten the nut (5) with the wrench only enough to

engage the boss (6).

D_ net ove_lghten as this Will restrict movement.

8. Mo_ the stop nuts (;1) and depth pointer to the

upper-most position and check the tension whi_e

turning the feed handles.

9. _fthere is not enough tension on the spring, repeat

steps 3-& moving only one notch each time.

Proper tension is achieved when the auiH returns

gent_y to the fun up position when released.

10. When _nere _senough tension, replace the jam nut (4)

and tighten the inner nut (5) but do not overtighten

11 Rotate the handle to check the auil_for unrestricted

movement. If the movement is too tight, _oosen the

iam nut (4) and slightly _oosen the inner nu[ (5_,

Reti_hten the _am nut.

Figo N

\

ANGULAR PLAY OFTNE SPINDLE (FIG. O}

Move the spindle to the bwest downward position, take it

in your hands, and try to make it revolve about its axis. If

there is too much p}a_; proceed as follows:

1 Loosen the lock nut (1),

2. Turn the screw (2} cfockwise to eliminate the play but

without obstructing the upward and downward motion

of the spindle (a little bit of play is normat),

3. Tighten the lock nut (1).

ON / OFF SWITCH (F_G. p}

The _N / OFF _t_:_ _s a remorse, yellow plastic key.

With _e key removed from the sw_tch, unauthorized and

hazardous use by children and othe_ is minimized,

1 To turn _e drill pre_ _ON", insert key (1) into the slot of

the S_ r(2), and rnqve the switch upward to the _N"

2, To turn the drill press "OFF* move the switch

dOWnward°

3o To loc_ the _ch in the °OFF posit_orb _sp #_e end.

or yellow part, of toggle, and #ullA_ut.

4. _%':_ththe sw_tchkey re_, _ switc, z,_lir_t operate°

& _ the s_ch key is rem_ while the _lt press is

_nning, _ can _ turned "OFF" but cannot be restarted

w_out i_se_ng the _#ch key

Nways lock the switch "OFF_ when the ddll press is not in

use, Remove the key and keep it in a safe place.

in the event of a power failure, Mown fuse, or tripped circuit

breaker, turn the s_i_ch _FF" ar_ _rnove th_ k_; _eventing

an accidenta! startup when the power comes one

Fbo P

12

Loading ...

Loading ...

Loading ...