1 2 3 4

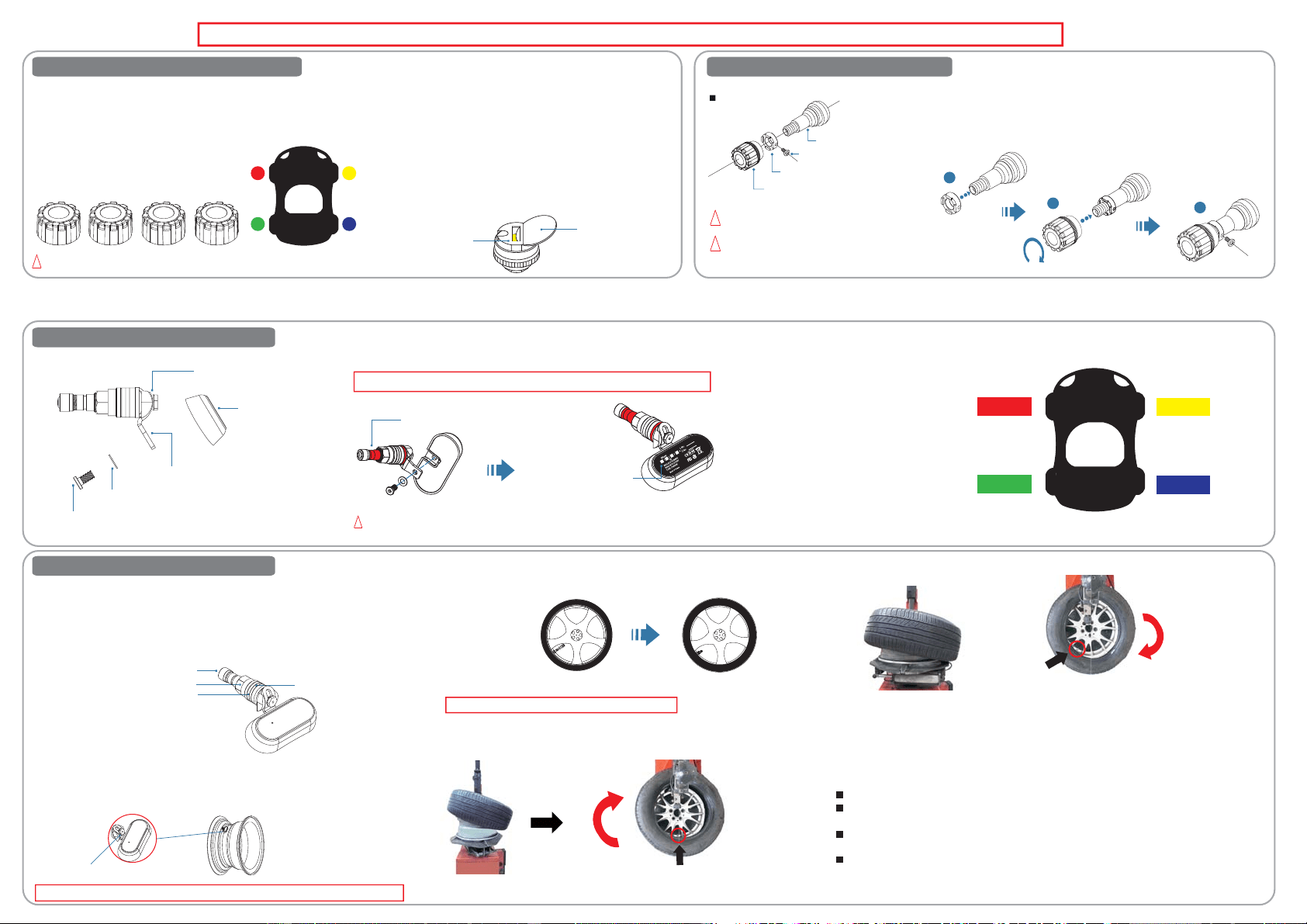

External Sensor

1 2

3 4

During sensor installation please check and make sure there are no cracks or aging on the tyre valve, and should be checked regularly to enhance driving safety.

1.

The installation of tire pressure sensors

Battery spring

Coin / Metal object

!

Make sure sensor body does not mix up with other sensor cap.

As each sensor has its own position, you have to make sure it’s in the

pre-set position. When inserting batteries in every sensor, please

don’t mix up sensor caps and every sensor has their own positions.

Please check the sensor map for guidance for user to install.

(1) means “ Front Left Tire ”.

(2) means “ Front Right Tire”.

(3) means “ Rear Left Tire ”.

(4) means “ Rear Right Tire ”.

Note:

Due to the sensor consuming very small battery power, so that the

remaining battery power could be retained for some time. In the event

the sensor resets or causes malfunctions, battery replacement may be

recommended. Power will need to be discharged from the sensor,

please follow these steps:

A. Use a metal object, such as coins, keys... etc., insert into the sensor

at the same time touching the battery metal holder and yellow color

area (battery holders negative), to achieve the power discharge. As

shown in the photo.

B. Then re-insert the new CR1632 lithium battery into sensor.

2.

Anti-theft tool for sensor (Optional)

Valve

Anti-theft fixed ring

Hex socket screw

Sensor

Part location A. Place the ring on the valve.

B. Install the sensor ( turn 5~7 times).

C. Use hex key to tight anti theft ring ( torque 0.71kg-cm (6.95N.cm)) make

sure the ring is not loose.

A

B

C

!

Screw and ring tighten distance is 0.7mm.

!

Make sure the screw is facing outward.

※ Hex key size:ψ2.5mm

Internal Sensor (Not Available in Australia/New Zealand)

1.

The installation of INTERNAL sensors

Insert disc-shaped washer into the hex socket cap screws, then assemble

the valve nozzle with sensor body and tight it with hex key. (Recommended torque

is around 1.7N•m)

!

Please verify the internal type sensor position and the valve stem color to avoid

Mistransplant.

As each sensor has its own position and color, you have to make sure its pre-set position. Every sensors have

own positions and sensors map could give guidance for user to install.

Red means “ Front Left Tire ”.

Yellow means “ Front Right Tire ”.

Green means “ Rear Left Tire ”.

Blue means “ Rear Right Tire ”.

Red

Yellow

Green

Blue

After complete installation, please make sure the Hex socket cap screws is tight.

Hex socket cap screws

Disc-shaped washer

Air valve nozzle accessories

Sensor body

Screw for the valve nozzle

Relative wheel position

Red→1、Yellow→2

Green→3、Blue→4

Valve stem color

(Red、Yellow、Green、Blue)

A. Disassemble the wheel from the car.

B. Deflate the disassembled wheel.

C. Use tire changer to take apart the tire and rim.

D. Take out the old valve from rim.

E. Screw off the Valve cover, rim nut, plastic spacer and Rubber O

ring on the sensor.

F. Use a open-end 7mm wrench to loose the valve nozzle screws, and

then follow the instruction photo below to insert the sensor to a proper

location on the rim, and adjusted to the proper angle, and then tighten

the valve screw. (Recommended torque is around 1.7N•m)

2.

The installation of INTERNAL sensors

After complete installation, please make sure the screw for the valve nozzle is tight.

Valve cover

rim nut

plastic spacer

Rubber O ring

Screw for the valve nozzle

G. Fix the sensor on the rim by screwing the rim nut onto the sensor. Do not

use destructive force to fix the rim nut for protection from damage. (Never

use excessive force to avoid damage to the sensor recommended torque

is around 0.9N•m)

H. Install the tire on the rim steps are as following

(1) Place the sensor on tyre remover machine and to adjust the position of

the rotating platfrom on the 6 o'clock position then install the tire

properly in clock wise direction. As the picture shown.

Sensor location should be

in around 6 o'clock position

Wheel rotational

direction

Installer stand location

Precaution: avoid the tire bead touching the sensor.

Note:

It is necessary to ask for the assistance from a professional for the tire installation.

It needs to adjust the tire position to fit or disassemble the tire, so that the sensor can be kept

away from the running location of the tire changer to prevent any damages on the sensor.

Every sensor has its separately specific marking for different tire position, please make sure to

install the sensor to each tire in order.

The sensor is an electronic detector powered by a lithium battery. If there is insufficient power in the

sensor, the sensor will send back insufficient power code tothe receiver module. If the power is

insufficient, need to replace a new sensor to ensure the normal operation of the system to update the

correct tire information.

(2) Refitting the tire bead, please place the sensor approximately 7 o’clock position as the picture

shown.

Wheel rotational

direction

Sensor location should be

in around 7 o'clock position

Installer stand location

I. Use tire changer to fit the tire on the rim, then inflate the tire with standard tire pressure, so monitor

will show the real time tire pressure value.

J. Spray soap water around the valve stem area to check for air leakage.

K. Make balancing testing and correcting for wheel on the balancing machine.

Loading ...