Loading ...

Loading ...

Loading ...

CONNECTIONS

*_ HORIZONTAL

RIGHT

APPLICATION

SUPPORT

RAIL

BRACKET

DRAIN

SUPPORT

BRACKET

SUPPORT

RAiL

BRACKET

DRAIN PAN

PRIMARY

HORIZONTAL RIGHT

SECONDARY DRAIN

HORIZONTAL RIGHT

A00071

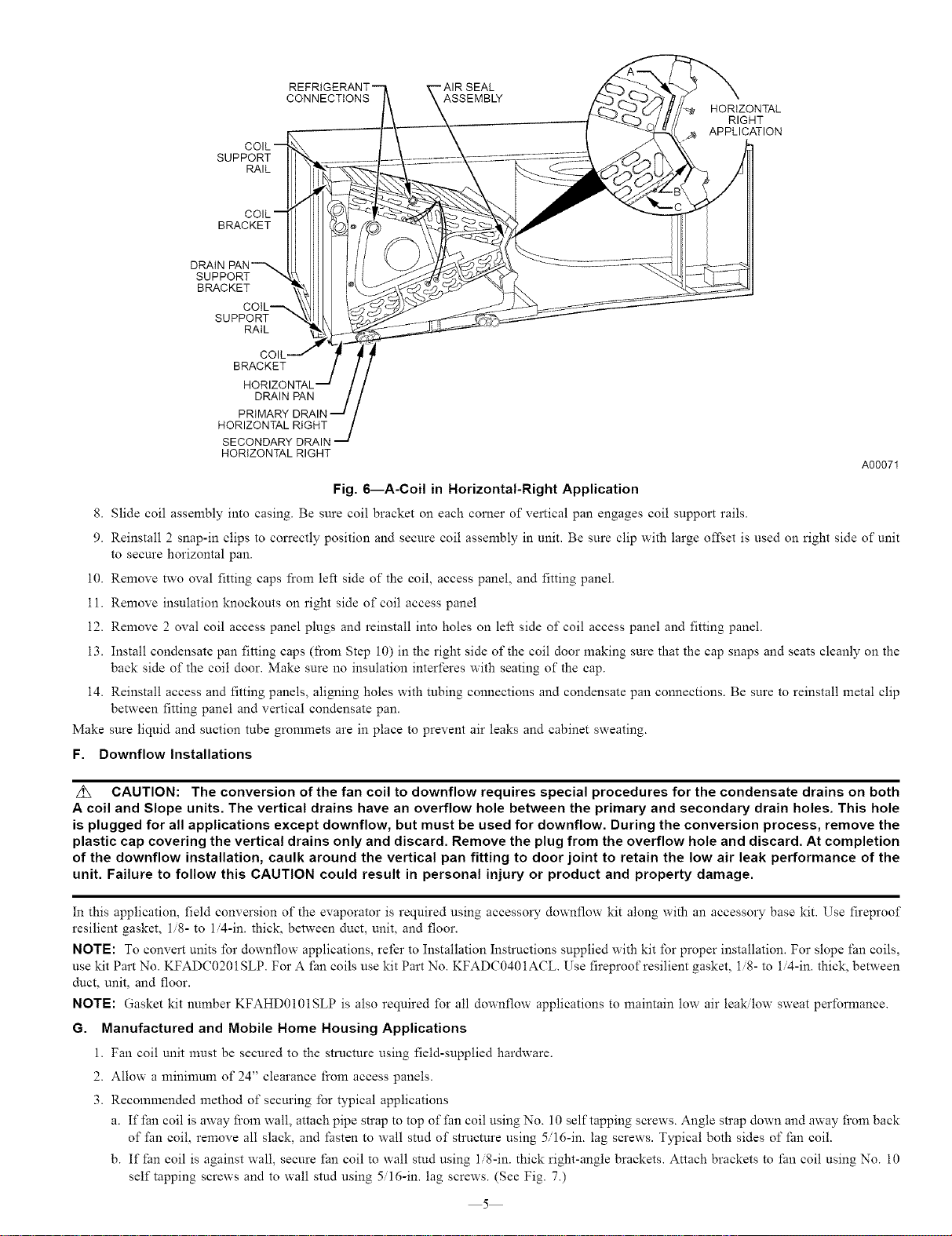

Fig. 6--A-Coil in Horizontal-Right Application

8. Slide coil assembly into casing. Be sure coil bracket on each corner of vertical pan engages coil support rails.

9. Reinstall 2 snap-in clips to con'ectly position and secure coil assembly in unit. Be sure clip with large of I;et is used on right side of unit

to secure horizontal pan.

i0. Remove two oval fitting caps from left side of the coil, access panel, and fitting panel.

11. Remove insulation knockouts on right side of coil access panel

12. Remove 2 oval coil access panel plugs and reinstall into holes on left side of coil access panel and fitting panel.

13. Install condensate pan fitting caps (from Step 10) in the right side of the coil door making sure that the cap snaps and seats cleanly on the

back side of the coil door. Make sure no insulation interferes with seating of the cap.

14. Reinstall access and fitting panels, aligning holes with tubing connections and condensate pan connections. Be sure to reinstall metal clip

between fitting panel and vertical condensate pan.

Make sure liquid and suction tube grommets are in place to prevent air leaks and cabinet sweating.

F. Downflow Installations

z_ CAUTION: The conversion of the fan coil to downflow requires special procedures for the condensate drains on both

A coil and Slope units. The vertical drains have an overflow hole between the primary and secondary drain holes. This hole

is plugged for all applications except downflow, but must be used for downflow. During the conversion process, remove the

plastic cap covering the vertical drains only and discard. Remove the plug from the overflow hole and discard. At completion

of the downflow installation, caulk around the vertical pan fitting to door joint to retain the low air leak performance of the

unit. Failure to follow this CAUTION could result in personal injury or product and property damage.

In this application, field conversion of the evaporator is required using accessory downflow kit along with an accessory base kit. Use fireproof

resilient gasket, 1/8- to 1/4-in. thick, between duct, unit, and floor.

NOTE: To convert units lbr downflow applications, refer to Installation Instructions supplied with kit for proper installation. For slope fan coils,

use kit Part No. KFADC0201SLP. For A fan coils use kit Part No. KFADC0401ACL. Use fireproof resilient gasket, 1/8- to ii4-in, thick, between

duct, unit, and floor.

NOTE: Gasket kit number KFAHD0101SLP is also required for all downflow applications to maintain low air leak.low sweat performance.

G. Manufactured and Mobile Home Housing Applications

l. Fan coil unit must be secured to the structure using field-supplied hardware.

2. Allow a minimum of 24" clearance from access panels.

3. Recommended method of securing lbr typical applications

a. If fan coil is away from wall, attach pipe strap to top of_an coil using No. 10 self tapping screws. Angle strap down and away from back

of fan coil, remove all slack, and _asten to wall stud of structure using 5/16-in. lag screws. Typical both sides of _an coil.

b. If _an coil is against wall, secure fan coil to wall stud using 1/8-in. thick right-angle brackets. Attach brackets to Pan coil using No. i0

self tapping screws and to wall stud using 5/16-in. lag screws. (See Fig. 7.)

5

Loading ...

Loading ...

Loading ...