Loading ...

Loading ...

Loading ...

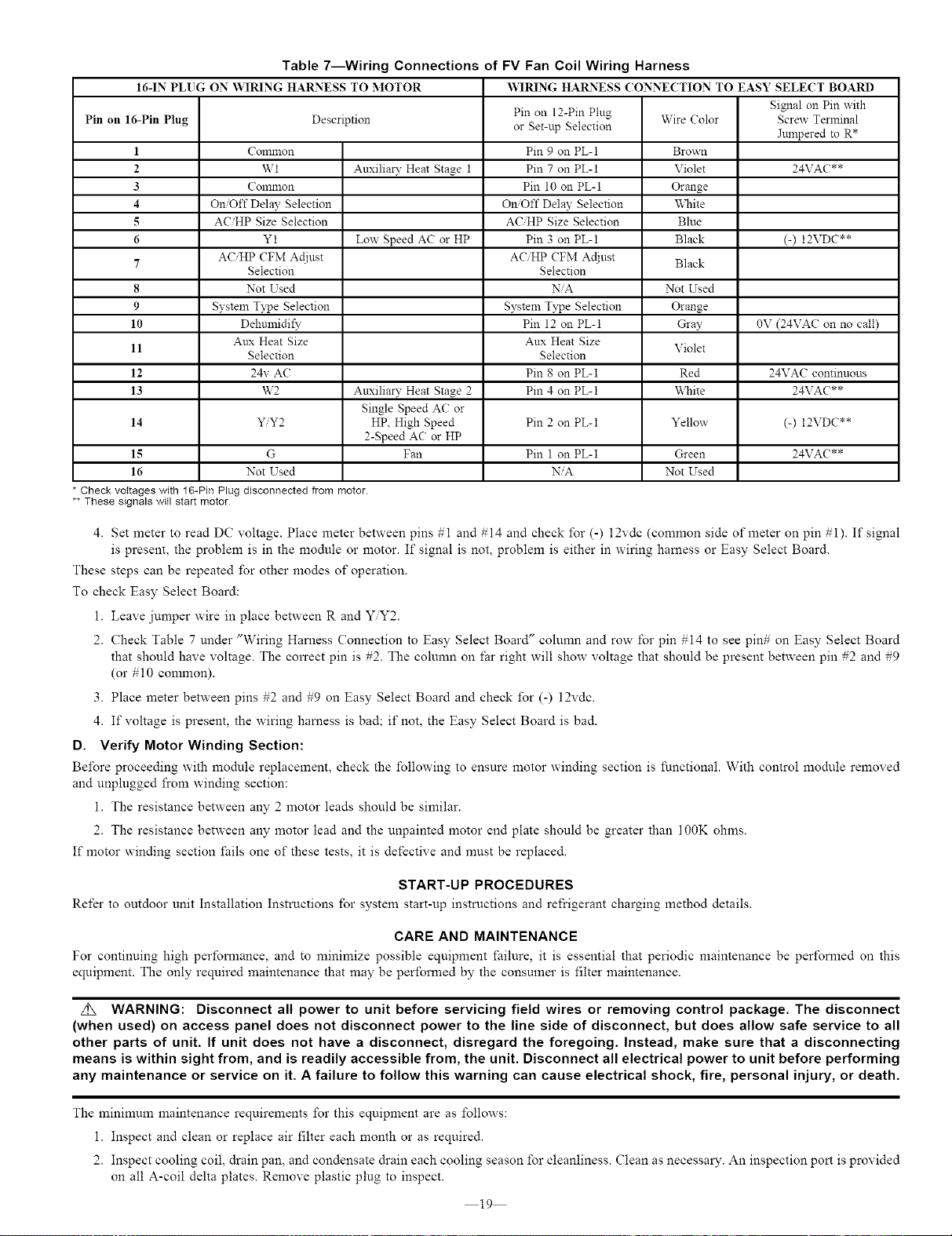

Table 7---Wiring Connections of FV Fan Coil Wiring Harness

16-IN PLUG ON WIRING HA1LNESS TO MOTOR _][RING HARNESS (ONNE(TION TO EASY SELECT BOARD

Pin on 16-Pin Plug Description

1 Common

2 W1

3 Common

4 On/Off Delay Selection

5 ACiHP Size Selection

6 Y1

ACiHP CFM Actiust

7

Selection

8 Not Used

9 System T3_peSelection

10 Dehmnidify

Aux Heat Size

11

Selection

12 24v AC

13 W2

14 Y/Y2

15 G

16 Not Used

Check voItages with 16-Pin Plug disconnected from motor.

These signals will start motor

Signal on Pin with

Pin on 12-Pin Plug Wire Color Screw Terminal

or Set-up Selection

Jnmpered to R*

Pin 9 on PL-1 Brown

Anxilia_" Heat Stage 1 Pin 7 on PL-1 Violet 24VAC**

Pin 10 on PL-1 Orange

On/Off Delay Selection White

ACiHP Size Selection Blue

Low Speed AC or HP Pin 3 on PL-1 Black (-) 12VDC**

ACHP CFM Adiust Black

Selection

NiA Not Used

System Type Selection Orange

Pin 12 on PL-1 Gray 0V (24VAC on no call)

Aux Heat Size

Violet

Selection

Pin 8 on PL-1 Red 24VAC continuous

Anxilia_" Heat Stage 2 Pin 4 on PL-1 White 24VAC**

Single Speed AC or

HP. High Speed Pin 2 on PL-1 Yellow (-) 12VDC**

2-Speed AC or HP

Fan Pin 1 on PL-1 Green 24VAC**

NiA Not Used

4. Set meter to read DC voltage. Place meter between pins #1 and #14 and check for (-) 12vdc (common side of meter on pin #1). If signal

is present, the problem is in the module or motor. If signal is not, problem is either in wiring hamess or Easy Select Board.

These steps can be repeated for other modes of operation.

To check Easy Select Board:

1. Leave jumper wire in place between R and Y/Y2.

2. Check Table 7 under "Wiring Haruess Connection to Easy Select Board" column and row for pin #14 to see pin# on Easy Select Board

that should have voltage. The correct pin is #2. The column on far right will show voltage that should be present between pin #2 and #9

(or #10 common).

3. Place meter between pins #2 and #9 on Easy Select Board and check for (-) 12vdc.

4. If voltage is present, the wiring haruess is bad; if not, the Easy Select Board is bad.

D. Verify Motor Winding Section:

Before proceeding with module replacement, check the following to ensure motor winding section is functional. With control module removed

and unplugged from winding section:

1. The resistance between any 2 motor leads should be similar.

2. The resistance between any motor lead and the unpainted motor end plate should be greater than 100K ohms.

If motor winding section fails one of these tests, it is defective and must be replaced.

START-UP PROCEDURES

Refer to outdoor unit Installation Instructions for system start-up instructions and refrigerant charging method details.

CARE AND MAINTENANCE

For continuing high perfomaance, and to minimize possible equipment failure, it is essential that periodic maintenance be performed on this

equipment. The only required maintenance that may be performed by the consumer is filter maintenance.

z_X WARNING: Disconnect all power to unit before servicing field wires or removing control package. The disconnect

(when used) on access panel does not disconnect power to the line side of disconnect, but does allow safe service to all

other parts of unit. If unit does not have a disconnect, disregard the foregoing. Instead, make sure that a disconnecting

means is within sight from, and is readily accessible from, the unit. Disconnect all electrical power to unit before performing

any maintenance or service on it. A failure to follow this warning can cause electrical shock, fire, personal injury, or death.

The mininmm maintenance requirements for this equipment are as follows:

1. Inspect and clean or replace air filter each month or as required.

2. Inspect cooling coil, drain pan, and condensate drain each cooling season for cleanliness. Clean as necessary. An inspection port is provided

on all A-coil delta plates. Remove plastic plug to inspect.

19

Loading ...

Loading ...

Loading ...