Loading ...

Loading ...

Loading ...

Page 32

INSTALLATION INSTRUCTIONS

CAUTION – The conical ring on the valve has an important sealing

function together with the sealing seat in the caps.

Ensure that you do not damage the cone and that you

keep the cap free of dirt and dust.

• After completing steps 1-6, check that all the connections are sealed

correctly using leak detection spray or soap suds. If any bubbles form,

the system has a leak and the screw connectors must be retightened

using an open-ended spanner.

• Start the equipment so that the operating pressures build up inside it.

Check all the connectors again for signs of leaks: (a) during cooling

mode. (b) in heating mode. If any bubbles form, the system has a leak

and the screw connectors must be re-tightened using an open-ended

spanner.

IMPORTANT: The unit with the quick connectors does not

require vacuum pumping.

Market Sampling Test Guidelines

Pressure-maintaining refrigerant is available in the indoor equipment

and the refrigerant pipe (Different models have different refrigerant

quantities). The installer must use the original refrigerant pipe.

Wrap the Piping

1. Use the insulation sleeve to wrap the joint part the indoor unit and

the refrigerant pipe, and then use the insulating material to pack and

seal insulation pipe, to prevent generation of condensate water on the

joint part.

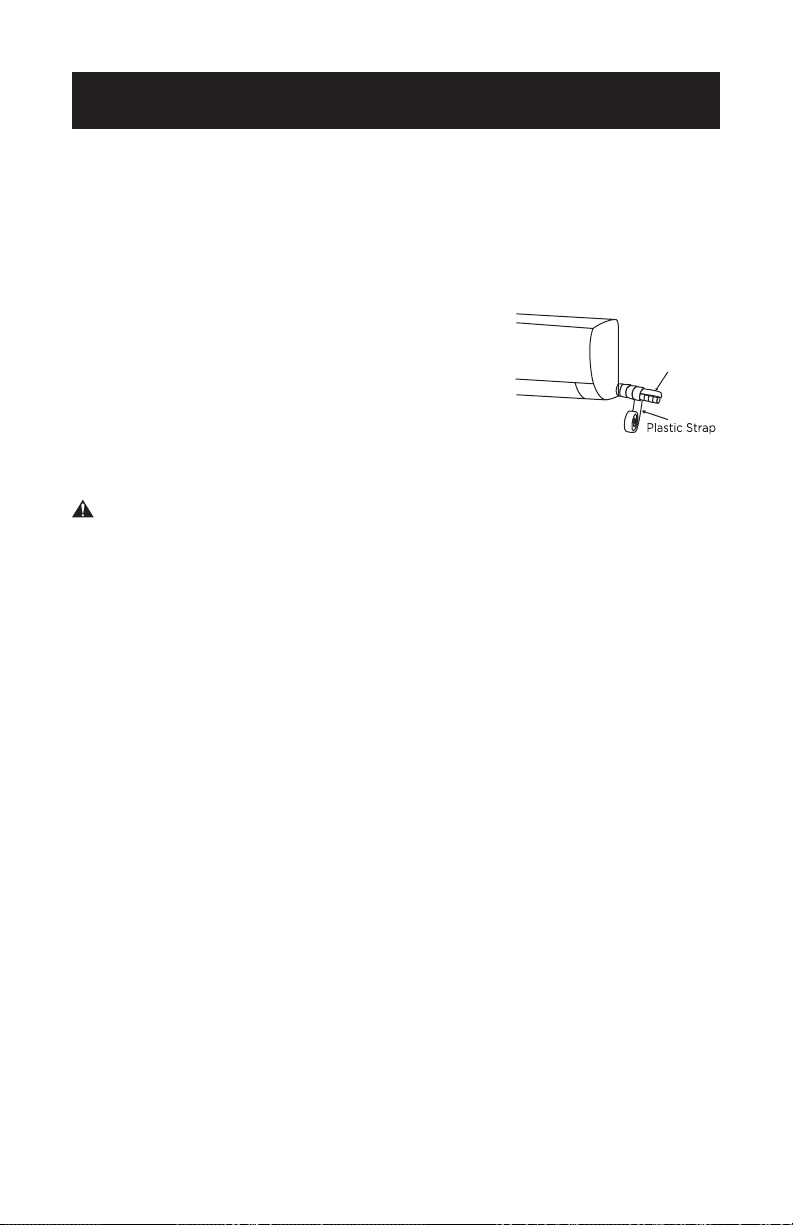

2. Connect the water outlet with drain hose,

and make the refrigerant pipe, cables, and

the drain hose straight.

3. Use plastic cable ties to wrap the refrigerant

pipes, cables and drain hose. Run the pipe

sloping downward shown in the following table.

Refrigerant Pipe

Drain Hose

and Cables

Loading ...

Loading ...

Loading ...