Loading ...

Loading ...

Loading ...

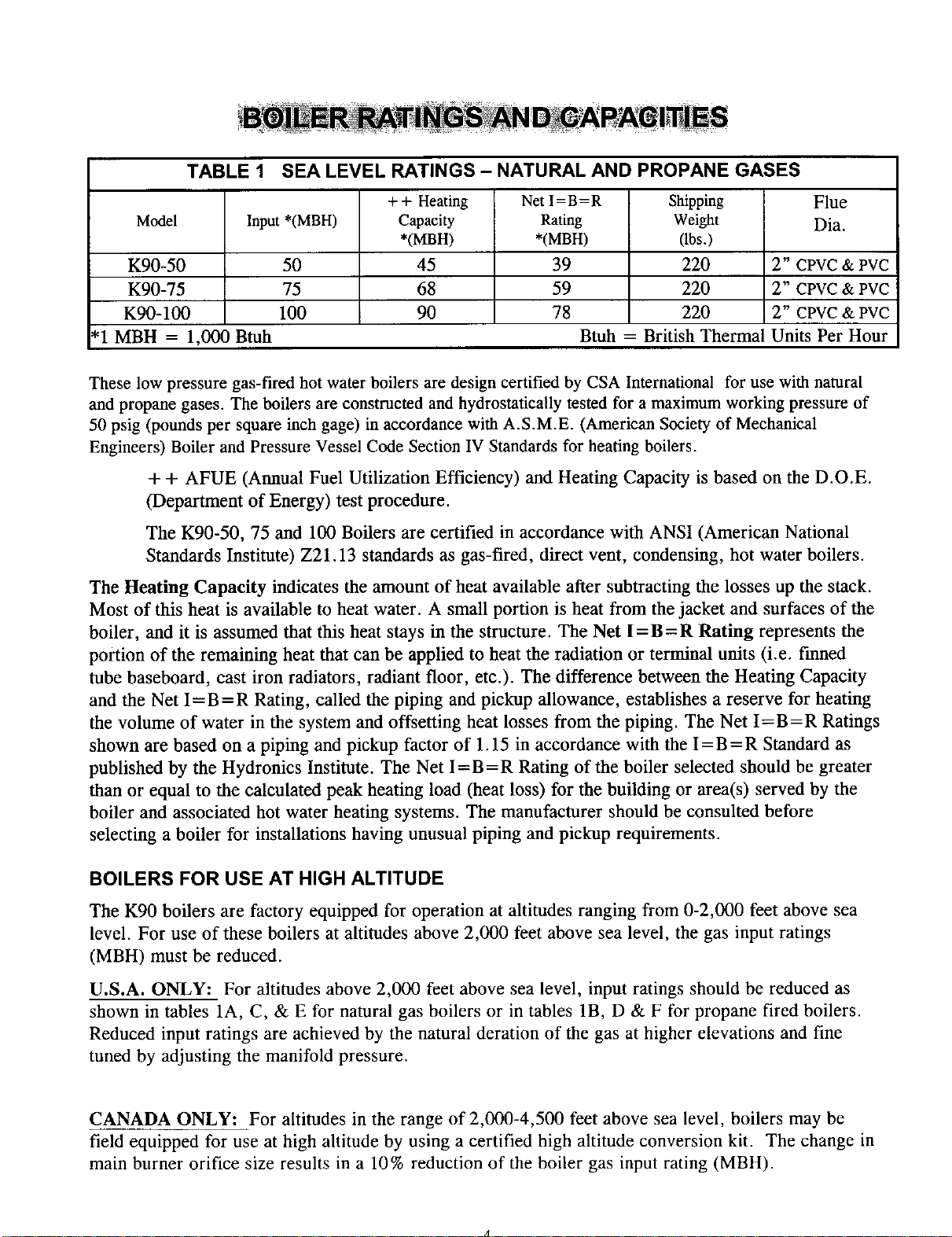

TABLE 1 SEA LEVEL RATINGS - NATURAL AND PROPANE GASES

+ + Heating Net I =B =R Shipping Flue

Model Input *(MBH) Capacity Rating Weight Dia.

*(MBH) *(MBH) (lbs.)

K90-50 50 45 39 220 2" CPVC & Pvc

K90-75 75 68 59 220 2" CPVC & Pvc

K90-100 100 90 78 220 2" cPVC & Pvc

"1 MBH = 1,000 Btuh Btuh = British Thermal Units Per Hour

These low pressure gas-fired hot water boilers are design certified by CSA International for use with natural

and propane gases. The boilers are constructed and hydrostatically tested for a maximum working pressure of

50 psig (pounds per square inch gage) in accordance with A.S.M.E. (American Society of Mechanical

Engineers) Boiler and Pressure Vessel Code Section IV Standards for heating boilers.

+ + AFUE (Annual Fuel Utilization Efficiency) and Heating Capacity is based on the D.O.E.

(Department of Energy) test procedure.

The K90-50, 75 and 100 Boilers are certified in accordance with ANSI (American National

Standards Institute) Z21.13 standards as gas-fired, direct vent, condensing, hot water boilers.

The Heating Capacity indicates the amount of heat available after subtracting the losses up the stack.

Most of this heat is available to heat water. A small portion is heat from the jacket and surfaces of the

boiler, and it is assumed that this heat stays in the structure. The Net I=B=R Rating represents the

portion of the remaining heat that can be applied to heat the radiation or terminal units (i.e. finned

tube baseboard, cast iron radiators, radiant floor, etc.). The difference between the Heating Capacity

and the Net I=B=R Rating, called the piping and pickup allowance, establishes a reserve for heating

the volume of water in the system and offsetting heat losses from the piping. The Net I=B=R Ratings

shown are based on a piping and pickup factor of 1.15 in accordance with the I=B=R Standard as

published by the Hydronics Institute. The Net I=B=R Rating of the boiler selected should be greater

than or equal to the calculated peak heating load (heat loss) for the building or area(s) served by the

boiler and associated hot water heating systems. The manufacturer should be consulted before

selecting a boiler for installations having unusual piping and pickup requirements.

BOILERS FOR USE AT HIGH ALTITUDE

The K90 boilers are factory equipped for operation at altitudes ranging from 0-2,000 feet above sea

level. For use of these boilers at altitudes above 2,000 feet above sea level, the gas input ratings

(MBH) must be reduced.

U.S.A. ONLY: For altitudes above 2,000 feet above sea level, input ratings should be reduced as

shown in tables 1A, C, & E for natural gas boilers or in tables 1B, D & F for propane fired boilers.

Reduced input ratings are achieved by the natural deration of the gas at higher elevations and fine

tuned by adjusting the manifold pressure.

CANADA ONLY: For altitudes in the range of 2,000-4,500 feet above sea level, boilers may be

field equipped for use at high altitude by using a certified high altitude conversion kit. The change in

main burner orifice size results in a 10% reduction of the boiler gas input rating (MBH).

Loading ...

Loading ...

Loading ...