Loading ...

Loading ...

Loading ...

getting to know your band saw/sander

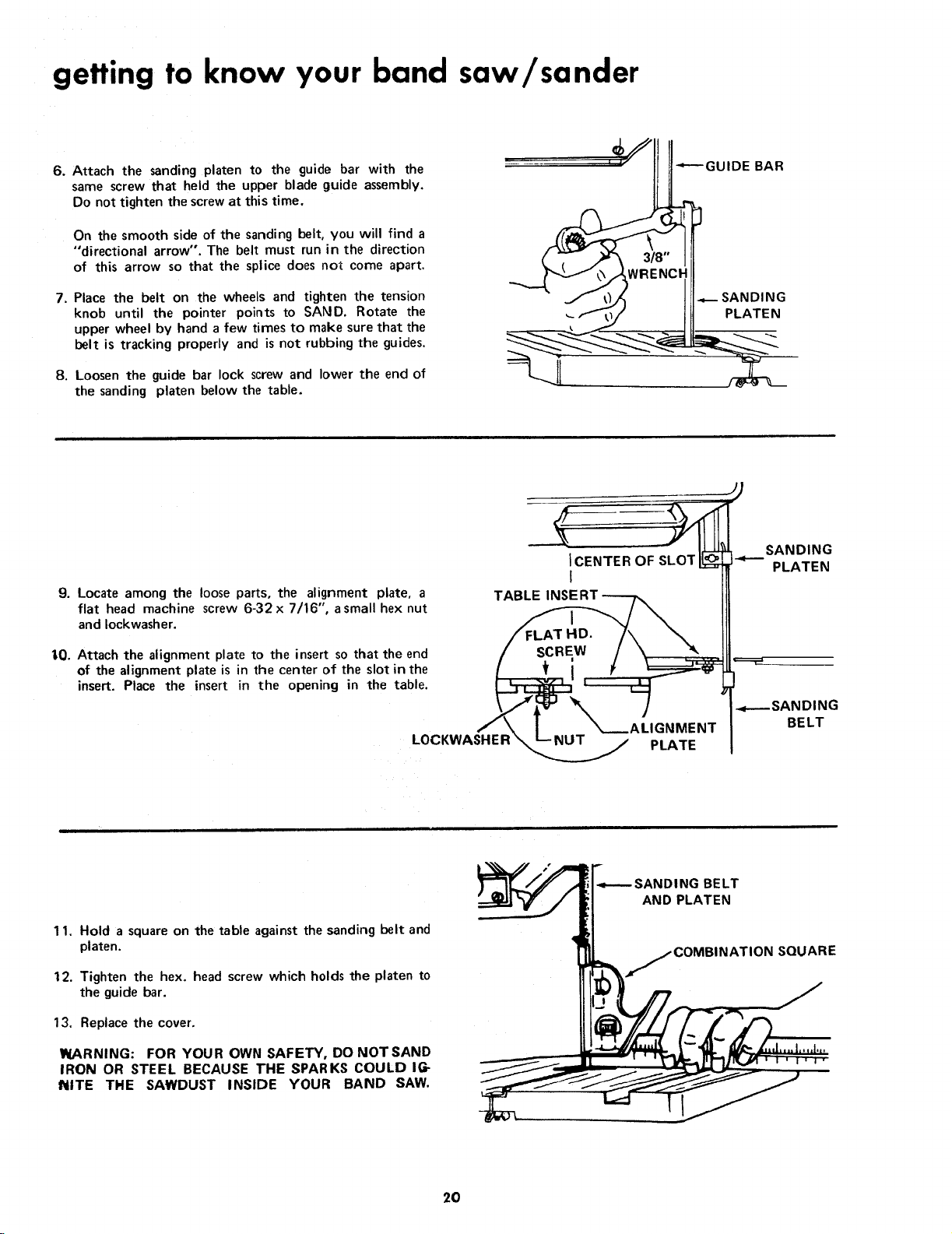

6. Attach the sanding platen to the guide bar with the

same screw that held the upper blade guide assembly.

Do not tighten the screwat this time.

On the smooth side of the sanding belt, you will find a

"directional arrow". The belt must run in the direction

of this arrow so that the splice does not come apart.

7. Place the belt on the wheels and tighten the tension

knob until the pointer points to SAND. Rotate the

upper wheel by hand a few times to make sure that the

belt is tracking properly and is not rubbing the guides.

8. Loosen the guide bar lock screw and lower the end of

the sanding platen below the table.

4-- SANDING

PLATEN

JCENTER OF SLOT L_

I

9. Locate among the loose parts, the alignment plate, a TABLE INSERT

flat head machine screw 6-32 x 7/16", asmall hex nut

and Iockwasher. /_LAT__..D.. _,

t0. Attach the alignment plate to the insert so that the end / SCREW /

of the alignment plate is in the center of the slot in the / _ i J/

insert. Place the insert in the opening in the table. _' r----"

Y@ALIGNMENT

LOCKWASHE PLATE

SANDING

.<p-=-

PLATEN

1 1. Hold a square on the table against the sanding belt and

platen.

12. Tighten the hex. head screw which holds the platen to

the guide bar.

13. Replace the cover.

• _,RNING: FOR YOUR OWN SAFETY, DO NOTSAND

IRON OR STEEL BECAUSE THE SPARKS COULD IG-

NITE THE SAWDUST INSIDE YOUR BAND SAW.

-,-----SANDING BELT

AND PLATEN

_,TION SQUARE

20

Loading ...

Loading ...

Loading ...