Loading ...

Loading ...

Loading ...

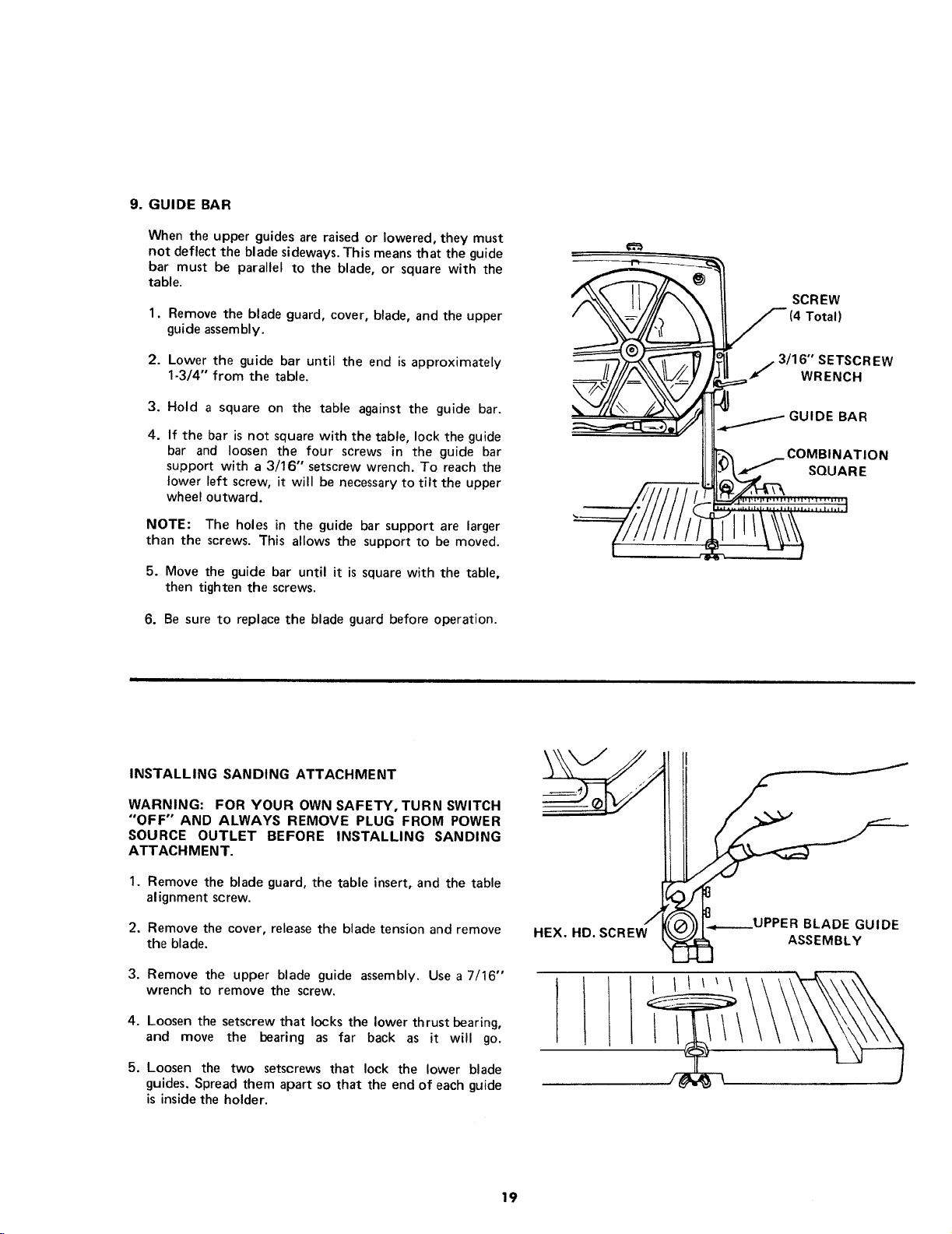

9.GUIDEBAR

When the upper guides are raised or lowered, they must

not deflect the blade sideways. This means that the guide

bar must be parallel to the blade, or square with the

table.

1. Remove the blade guard, cover, blade, and the upper

guide assembly.

2. Lower the guide bar until the end is approximately

1-3/4" from the table.

3.

4.

Hold a square on the table against the guide bar.

If the bar is not square with the table, lock the guide

bar and loosen the four screws in the guide bar

support with a 3/16" setscrew wrench. To reach the

lower left screw, it will be necessary to tilt the upper

wheel outward.

NOTE: The holes in the guide bar support are larger

than the screws. This allows the support to be moved.

5. Move the guide bar until it is square with the table,

then tighten the screws.

6. Be sure to replace the blade guard before operation.

=------_-_-_-_____=

__ SCREW

(4 Total)

_¢"_"_'_ _°il ,3/16" SETSCREW

J- W.ENCH

GU,OEBAR

INSTALLING SANDING ATTACHMENT

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND ALWAYS REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE INSTALLING SANDING

ATTACHMENT.

1. Remove the blade guard, the table insert, and the table

alignment screw.

2. Remove the cover, release the blade tension and remove

the blade.

3. Remove the upper blade guide assembly. Use a 7/16"

wrench to remove the screw.

4. Loosen the setscrew that locks the lower thrust bearing,

and move the bearing as far back as it will go.

5. Loosen the two setscrews that lock the lower blade

guides. Spread them apart so that the end of each guide

is inside the holder.

\ II

HEX. HD. SCREW_K((_))I"_---UPPER BLADE GUIDE

ASSEMBLY

19

Loading ...

Loading ...

Loading ...