Loading ...

Loading ...

Loading ...

Properlysupportroundmaterialsuchasdowel

rods.Theyhaveatendencytorollduringacut,

causingthebladeto"bite." To avoidthis, always

use a "v" block.

• Clear everything except the workpiece and

related supportdevices offthe table before

plugginginto power and turningthe saw on.

B PLAN THE WAY YOU WILL HOLD THE

WORKPIECE FROM START TO FINISH. Do not

hand hold pieces so small that yourfingers will

go under the work hold-down.

• BEFORE FREEING ANY JAMMED MATERIAL:

• Turn switch OFF.

• Wait for all moving parts to stop.

• Unplug the saw.

WHEN BACKING OUT OF THE WORKPIECE,

THE BLADE MAY BIND IN THE KERF (CUT).

THIS IS USUALLY CAUSED BY SAWDUST

CLOGGING UP THE KERF. IF THIS HAPPENS:

• Turn switch OFF,

• Wait for all moving parts to stop.

• Unplug the saw.

• Remove the blade from the blade holders.

• Remove the workpiece with blade from the table.

• Remove blade from workpiece.

&

WARNING: Before removing loosepieces from

the table, turnsaw off and waitfor all moving

parts to stop to avoid serious personal injury.

_. WARNING: When servicing, use onlyidentic&l

Craftsman replacement parts. Use of any other

part may create a hazard or cause product

damage.

WARNING: To prevent accidental starting that

could cause possible serious personal injury,

turn offand unplug the saw before maintainingor

lubricatingyour scroll saw.

GENERAL MAINTENANCE

Keep your Scroll Saw clean.

After cleaning the table top initially,apply a thin

coat of automobile type (paste) wax to the table

top so the wood slides easily while cutting.

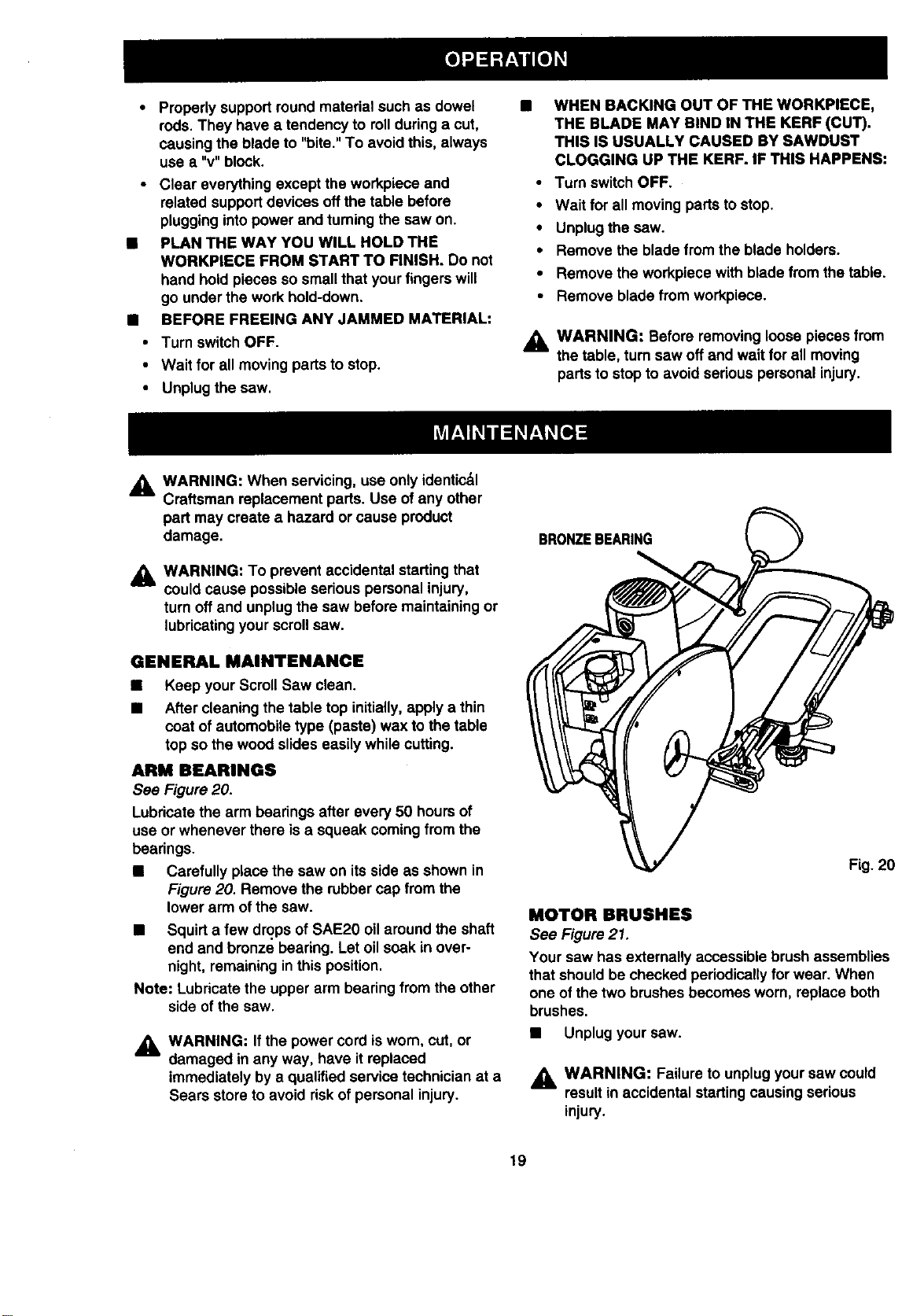

ARM BEARINGS

See Figure 20.

Lubricatethe arm bearings after every 50 hours of

use or whenever there is a squeak coming from the

bearings.

• Carefully place the saw on itsside as shown in

Figure 20. Remove the rubber cap from the

lower arm of the saw.

• Squirt a few drops of SAE20 oil around the shaft

end and bronze bearing. Let oil soak in over-

night, remaining in this position.

Note: Lubricatethe upper arm bearing from the other

side of the saw.

_k, WARNING: Ifthe power cord isworn, cut, or

damaged in any way, have it replaced

immediately by a qualified service technician at a

Sears store to avoid riskof personal injury.

BRONZEBEARING

MOTOR BRUSHES

See Figure21.

Your saw has externally accessible brush assemblies

that should be checked periodicallyfor wear. When

one of the two brushes becomes worn, replace both

brushes.

• Unplug your saw.

_, WARNING: Failure to unplugyour saw could

resultin accidental starting causing serious

injury.

19

Loading ...

Loading ...

Loading ...