Loading ...

Loading ...

Loading ...

HOLD DOWN FOOT/BLADE GUARD

The hold down foot should be lowered until it just

rests on top of the workpiece to prevent the workpiece

from lifting while cutting, but not so much that the

workpiece drags. The vertical portion provides a blade

guard to prevent accidental blade contact.

HOLD DOWN FOOT LOCK KNOB

Allows you to raise or lower the hold down foot/blade

guard and secure itat desired heights•

SAWDUST BLOWER

Keeps the line ofcut on workpiece clean for more

accurate scroll cuts.

SAWDUST EXHAUST

Your saw has a sawdust exhaust that fits a standard

shopvacuum hose. See Figure 13.

SAW TABLE

Your scrollsaw has an aluminum saw table that

provides a workingsurface to supportyour workpiece.

TABLE LOCK KNOB

Allowsyou totilt the table and lock itat the desired

angle up to45 degrees.

BEVEL SCALE

The bevel scale and indicator are locatedon the front

of the saw for easy viewing. They show the angle of

the table•

ZERO DEGREE STOP FOR TABLE

Located under the front of the saw table, the zero

degree stopallows easy returnand fine adjustment of

the zero degree relationshipbetween the table and

the blade.

Your Craftsman 16 in.scroll saw was fully assembled

at the factory. Beforeoperating thistool, itis important

to check all alignments and settings. Normal handling

during shipment may have changed settings.

_L WARNING: To avoid serious personal injury

from unexpected tool movement, always

securely mountscroll saw to a workbench.

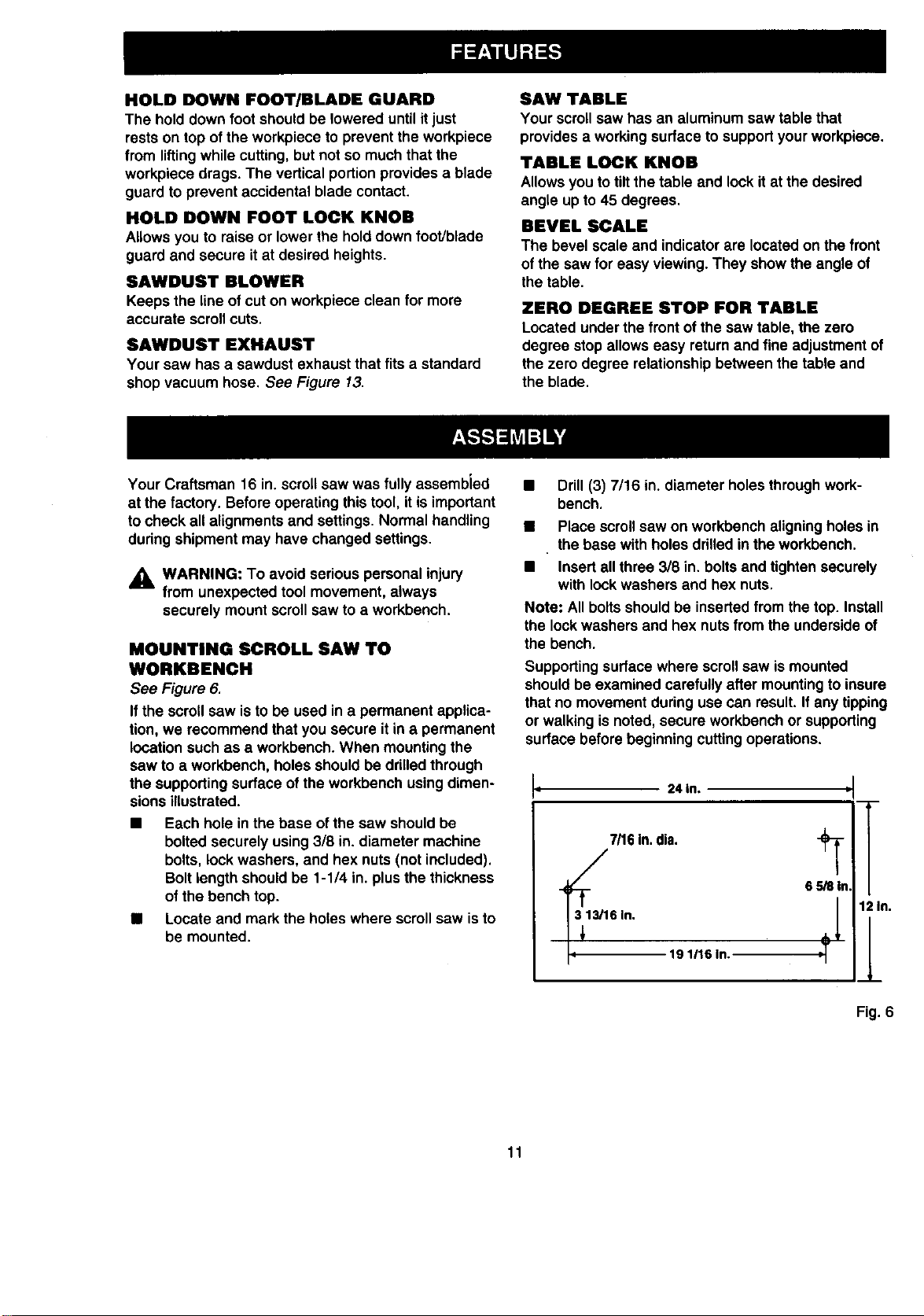

MOUNTING SCROLL SAW TO

WORKBENCH

See Figure 6.

If the scroll saw isto be used in a permanent applica-

tion, we recommend that you secure it in a permanent

location such as a workbench. When mountingthe

saw to a workbench, holes shouldbe drilledthrough

the supportingsurface ofthe workbench usingdimen-

sions illustrated.

• Each hole inthe base ofthe saw shouldbe

bolted securely using 3/8 in. diameter machine

bolts, lock washers, and hex nuts (not included).

Boltlength shouldbe 1-1/4 in. plus the thickness

ofthe bench top.

• Locate and mark the holes where scrollsaw is to

be mounted.

• Drill(3)7/16in. diameterholesthrough work-

bench.

Place scrollsaw on workbenchaligningholes in

the base with holes drilled in the workbench.

Insertall three 3/8 in. bolts and tighten securely

with lock washers and hex nuts.

Note: Allboltsshould be inserted from the top. Install

the lockwashers and hex nutsfrom the underside of

the bench.

Supporting surface where scrollsaw is mounted

shouldbe examined carefully after mountingto insure

that no movement during use can result. If any tipping

or walking is noted, secure workbench or supporting

surface before beginning cutting operations.

II

24 in.

7/16In.dia.

€ T'

6In.

19 1116 In.

.I

12 In.

Fig. 6

11

Loading ...

Loading ...

Loading ...