Loading ...

Loading ...

Loading ...

Part number 550-142-330/0421

9

SGO

OIL-FIRED NATURAL DRAFT STEAM BOILER — SERIES 4 — Boiler Manual

HOMEOWNERandSERVICETECHNICIAN—readandfollowcompletely.

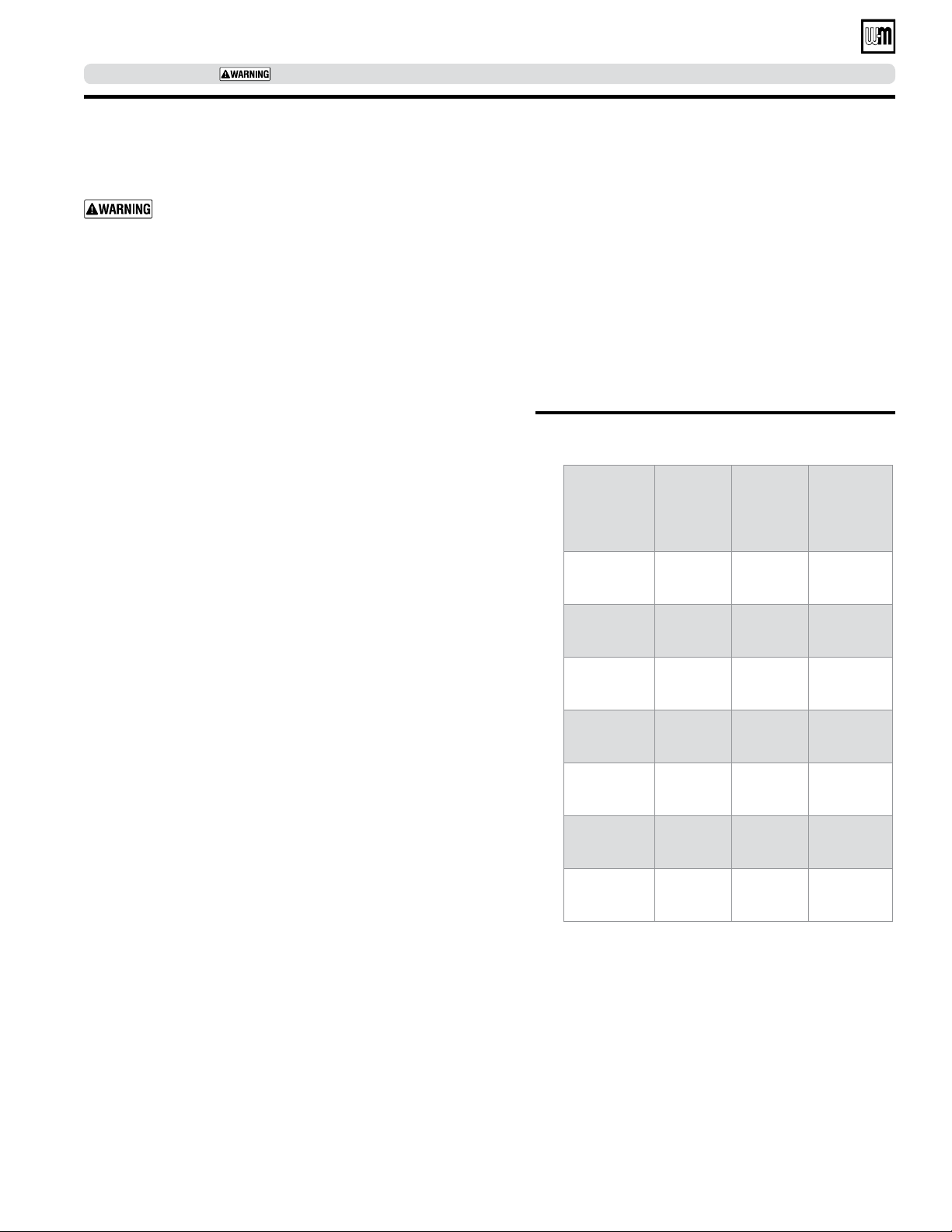

Table 1 Boiler foundation sizes

Provide air for combustion and ventilation

Do not install exhaust fan in boiler room.

Adequate combustion and ventilation air:

•Assures proper combustion.

•Reduces risk of severe personal injury or death from possible flue

gas leakage and carbon monoxide emissions.

Older buildings with single-pane windows, minimal weather-stripping

and no vapor barrier often provide enough natural infiltration and

ventilation without dedicated openings.

New construction or remodeled buildings are most often built tighter.

Windows and doors are weather-stripped, vapor barriers are used and

openings in walls are caulked. As a result, such tight construction is

unlikely to allow proper natural air infiltration and ventilation.

Follow state, provincial or local codes when sizing adequate combus-

tion and ventilation air openings. In absence of codes, use the follow-

ing guidelines when boiler is in a confined room (defined by NFPA

31 as less than 7200 cubic feet per 1 GPH input of all appliances in

area. A room 8 ft. high x 33.5 ft. x 33.5 ft. is 7200 cu. ft.):

•Provide two permanent openings — one within 12 inches of

ceiling, one within 12 inches of floor. Minimum height or length

dimension of each rectangular opening should be at least 3 inches.

•When inside air is used — each opening must freely connect with

areas having adequate infiltration from outside. Each opening

should be at least 140 sq. in. per 1 GPH input (1 sq. in. per 1000

Btu input) of all fuel-burning appliances plus requirements for

any equipment that can pull air from room (including clothes

dryer and fireplace).

When outside air is used — connect each opening directly or by ducts

to the outdoors or to crawl or attic space that freely connects with

outdoors. Size per below:

•Through outside wall or vertical ducts — at least 35 sq. in. per

1 GPH input (1 sq. in. per 4000 Btu input) of all fuel-burning

appliances plus requirements for any equipment that can pull

air from room (including clothes dryer and fireplace).

•Through horizontal ducts — at least 70 sq. in. per 1 GPH

boiler input (1 sq. in. per 2000 Btu input) of all fuel-burning

appliances plus requirements for any equipment that can pull

air from room (including clothes dryer and fireplace).

•Where ducts are used, they should have same cross-sectional

area as free area of openings to which they connect. Com-

pensate for louver, grille or screen blockage when calculating

free air openings. Refer to their manufacturer’s instructions

for details. If unknown, use:

•Wood louvers, which provide 20-25% free air.

•Metal louvers or grilles, which provide 60-75% free air.

Lock louvers in open position or interlock with equipment to prove

open before boiler operation.

Lay a foundation, if needed

Boiler may be installed on non-carpeted combustible

flooring.

For residential garage installation, install boiler so burner is

at least 18 inches above floor to avoid contact with gasoline

fumes.

A level concrete or masonry foundation is required when:

•Floor could possibly become flooded.

•Non-level conditions exist.

Solid concrete blocks can be used to create a pad.

Boiler

model

Length

inches

Width

inches

Minimum

height

inches

SGO-3

17 22 2

SGO-4

20 22 2

SGO-5

23 22 2

SGO-6

26 22 2

SGO-7

29 22 2

SGO-8

32 22 2

SGO-9

35 22 2

Before installing boiler (continued)

Loading ...

Loading ...

Loading ...