Loading ...

Loading ...

Loading ...

Part number 550-142-330/0421

39

SGO

OIL-FIRED NATURAL DRAFT STEAM BOILER — SERIES 4 — Boiler Manual

SERVICETECHNICIANONLY—readandfollowcompletely.

❏ Service. . . . . . . . . .

Gaugeglass

Normal waterline is halfway up gauge glass. Clean when needed.

1. Close lower gauge cock.

2. Open pet cock.

3. Open lower gauge cock and allow a small amount of water to

flush out through open pet cock.

4. Close pet cock.

5. Open lower gauge cock.

Boiler pressure must be low to eliminate potential

of severe burns.

If gauge glass breaks, close both gauge cocks. Replace

gauge glass. Do not replace with thin glass tubing.

Failure to comply could cause severe personal injury,

death or substantial property damage.

❏ Check/test. . . . . . . . . .

Boilerwaterline

Normal waterline is halfway up gauge glass.

Limitcontrols

Inspect and test the boiler limit control. Verify operation by turn-

ing control set point below boiler pressure. Boiler should cycle off.

Return dial to original setting.

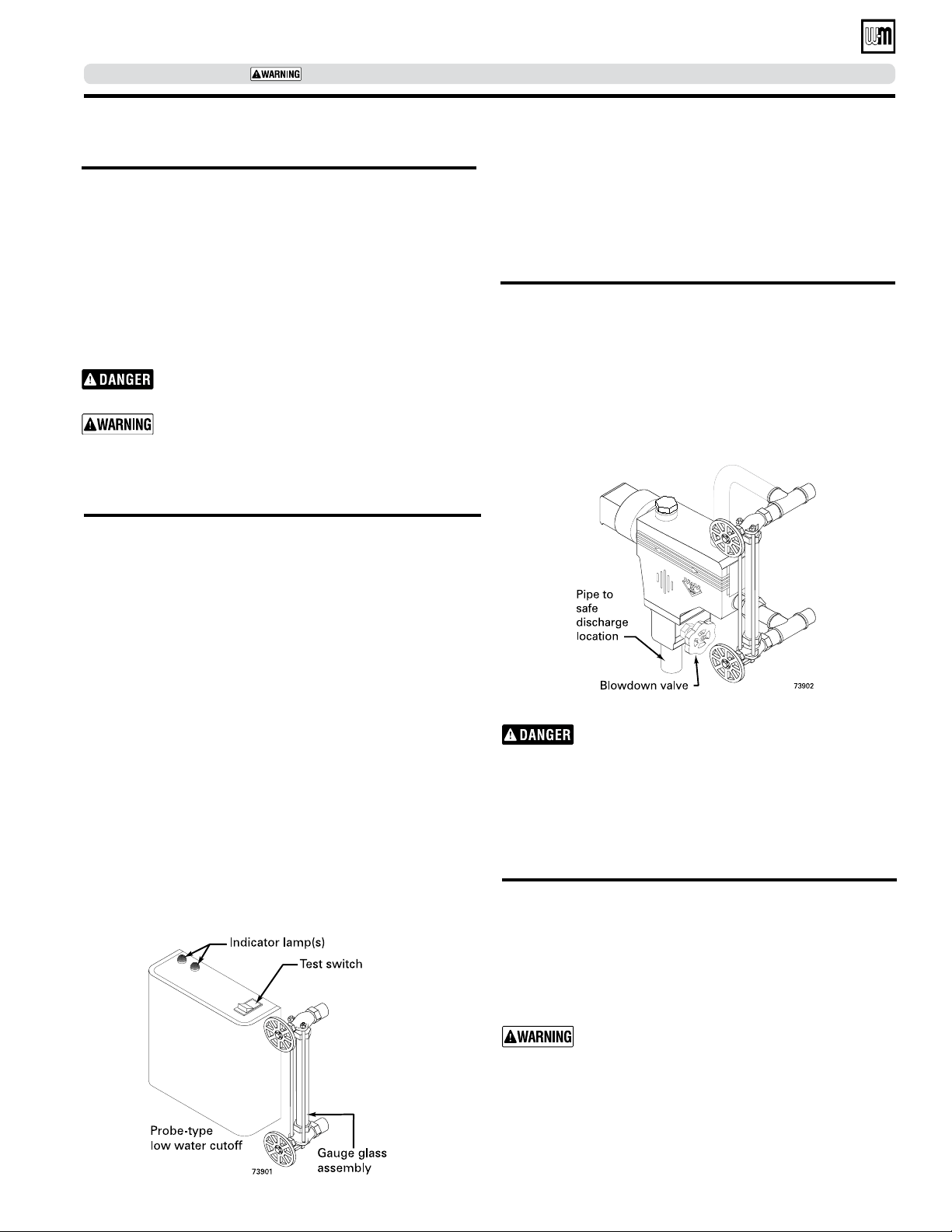

Lowwatercutoffs

Probe-type low water cutoff (see below)

Clean and test probe-type low water cutoff for proper operation.

Remove, inspect and clean the low water cutoff at least annually

before testing. Refer to low water cutoff manufacturer’s instruc-

tions in envelope assembly provided with boiler.

1. Turn off power to boiler and wait 5 minutes.

2. Drain water to bottom of gauge glass.

3. Turn on power.

4. Set thermostat to call for heat. Red neon lamp on lower water

cutoff should light.

5. Wait 5 minutes. Boiler should not fire.

6. Refill boiler to correct waterline. Red lamp should go off.

7. Wait 5 minutes. Boiler should fire.

8. Return thermostat to normal setting.

❏ Check/test. . . . . . . . . .

Float-type low water cutoff (when provided by others

— see below)

Clean and test float-type low water cutoff (when provided by

others) to clear float chamber of sediment.

1. Open blow down valve at bottom control.

2. Drain water into a bucket.

Scald potential. Boiler pressure must be low to avoid

the potential of severe burns from steam.

3. Check float-type low water cutoff for proper operation:

a. Turn operating control to call for heat.

b. Before water gets hot, drain to bottom of gauge glass.

Boiler should shut off after water level lowers a few inches.

c. Refill boiler to correct waterline. Boiler should come back on.

❏ Check monthly

Venting system

Visually inspect all parts or the flue gas venting system for

any signs of blockage, leakage or joints or deterioration of the

piping. Notify your qualified service technician at once if you

find any problem.

Failure to inspect the vent system as noted above and

have it repaired by a qualified service technician can

result in vent system failure, causing severe personal

injury or death.

Service and maintenance (continued)

Loading ...

Loading ...

Loading ...