Loading ...

Loading ...

Loading ...

Part number 550-142-330/0421

7

SGO

OIL-FIRED NATURAL DRAFT STEAM BOILER — SERIES 4 — Boiler Manual

HOMEOWNERandSERVICETECHNICIAN—readandfollowcompletely.

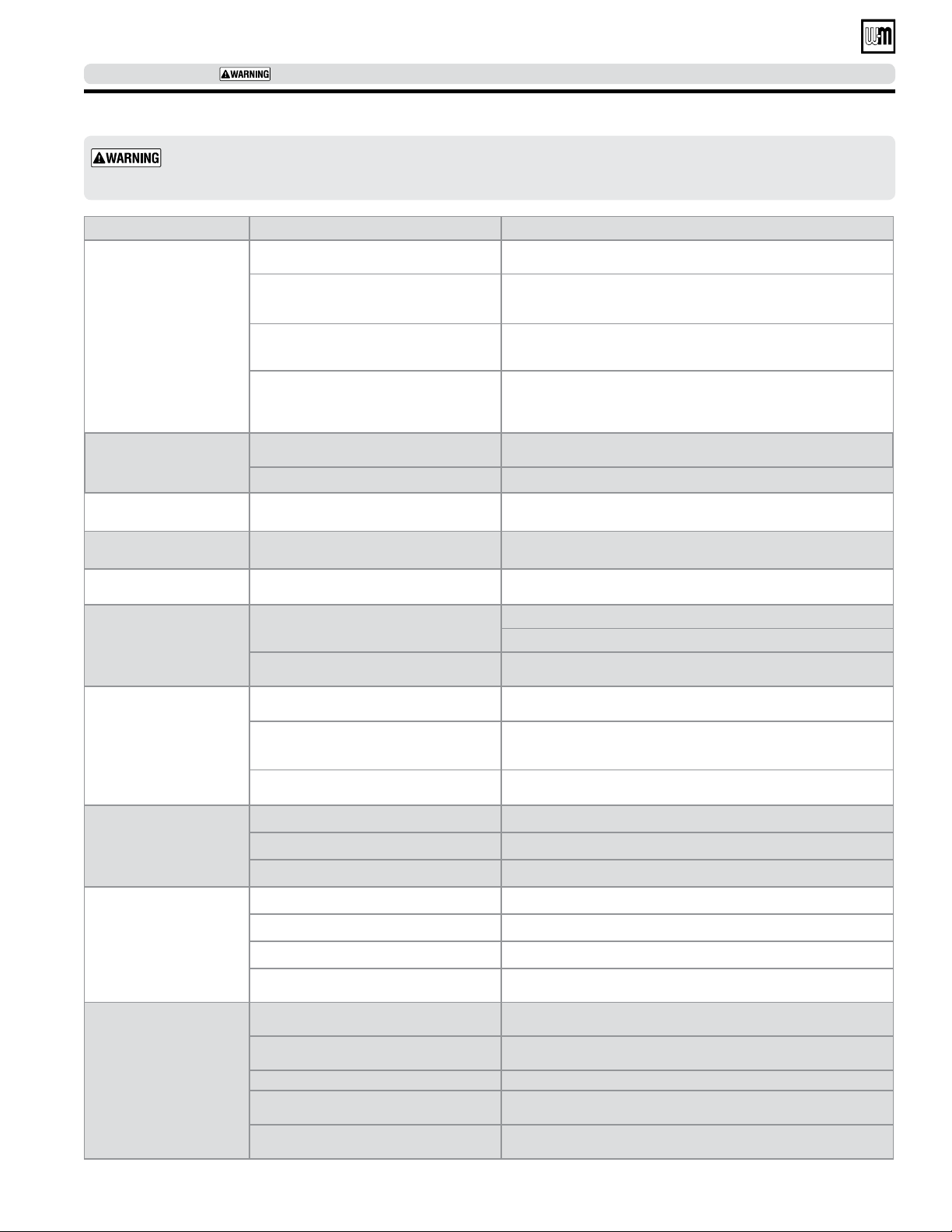

Troubleshooting

CommonproblemsCommoncausesPossiblecorrections

Rapid cycling -

burner

turns on and off frequently.

ermostat installed where dras or heat aect

reading.

Locate thermostat on inner wall away from heat sources or cool dras.

Heat anticipator setting in thermostat set

incorrectly.

Consult thermostat manufacturer instructions or set heat anticipator to

match current draw of circuit it is attached to. (Burner primary control, T-stat

switching relay coil, etc.).

Main and/or radiator vents not working properly

(one-pipe steam) or traps not working properly

(two-pipe steam).

Contact service technician to check, repair or replace air vents and traps.

Incorrect pressure limit setting. Set pressure cut-in and dierential according to system needs. Typical one and

two pipe systems need less than 2 psig. Typical cut-in setting is ½ -1 psi and

dierential of 1 psi. Try increasing dierential in ½ psi increments for longer

cycle times.

Frequent release of

water or steam through relief

valve.

Inoperative limit control.

If pressure in boiler is approaching 15 PSI, check pressure control setting,

operation & wiring. Replace if defective.

Incorrect or defective relief valve. Check for proper relief valve (15 psi). If opening at less than 15 psig, replace.

Needtofrequentlyadd

makeup water.

Leaks in boiler or piping.

Have qualied service technician repair leaks at once to avoid constant use of

makeup water.

Black or rust colored water

condition.

Black oxide or oxidation (rust) due to leaks in

boiler, air vents or piping. Improper pH.

Have qualied service technician repair leaks at once. Keep pH of water

between 7.0 to 8.5.

Popping or percolating noise

heard in boiler.

Mineral deposits in sections due to constant use

of makeup water. Or incorrect pH.

Have qualied service technician de-lime boiler and repair leaks at once to avoid

constant use of makeup water and check ph (7.0 to 8.5).

Metal flakes found in vent

outlet or vent — flue way

corrosion.

Contaminated combustion air supply. Remove any contaminating products. See page10 of this manual.

Provide outside air for combustion.

Condensation of combustion gases in ue ways. Have a qualied service technician check burner nozzle and oil pump pressure

for proper ring rate and check/adjust combustion settings with analyzer.

Some radiators or baseboard

units do not heat.

Main or radiator air vents (one pipe system) or

traps (two pipe system) not operating correctly.

Have qualied service technician inspect, repair or replace faulty air vents or

traps.

Incorrect pressure limit setting. Set pressure cut in and dierential according to system needs. Typical one and

two pipe systems need less than 2 psig. Typical cut in setting is ½ -1 psi and

dierential of 1 psi.

Clogged piping, valves or radiator. Or inoperable/

closed radiator valve.

Have qualied service technician clean or replace clogged components.

Water disappearing from

gauge glass and back into

system through return piping.

Incorrect Hartford loop piping. Have qualied service technician pipe boiler exactly as shown in boiler manual.

Check-valve inoperative. Have qualied service technician clean or replace check-valve.

Vacuum-breaker inoperative. Have qualied service technician clean or replace vacuum breaker.

Violent waterline fluctuations

surging

OR

Water passing into steam

mains priming.

Dirt, oil or other impurities in water. Have qualied service technician skim boiler.

Waterline too high. Have qualied service technician adjust waterline to normal height.

Incorrect piping. Have qualied service technician pipe boiler exactly as shown in boiler manual.

Sudden release of boiler steam pressure by action

of zone valves.

Have qualied service technician adjust valve operating time or install slow-

opening valves.

Domestic water from

tankless heater is hot then

suddenly turns cold.

Or

Domestic water from

tankless heater is always

lukewarm.

Mineral deposits insulate internal waterways of

heater.

Have qualied service technician delime or replace coil.

Boiler stop-leak compound has been added to

boiler water and is insulating outside of coil.

Have qualied service technician remove and clean coil and drain and ush

boiler to remove stop-leak.

Incorrect mixing valve setting for tankless heater. Have qualied service technician adjust mixing valve setting.

Domestic ow rate too high.

Have qualied service technician install ow check valve set to rating of

tankless heater.

Incorrect setting on tankless heater control.

Have qualied service technician raise tankless control setting. Adjust

dierential on tankless control to lower setting.

Homeowners — The problems and corrections below represent common situations that can occur.

There may be others not listed below. It is important always to contact a qualified service technician

if you have any questions about the operation of your boiler or system.

Loading ...

Loading ...

Loading ...