Loading ...

Loading ...

Loading ...

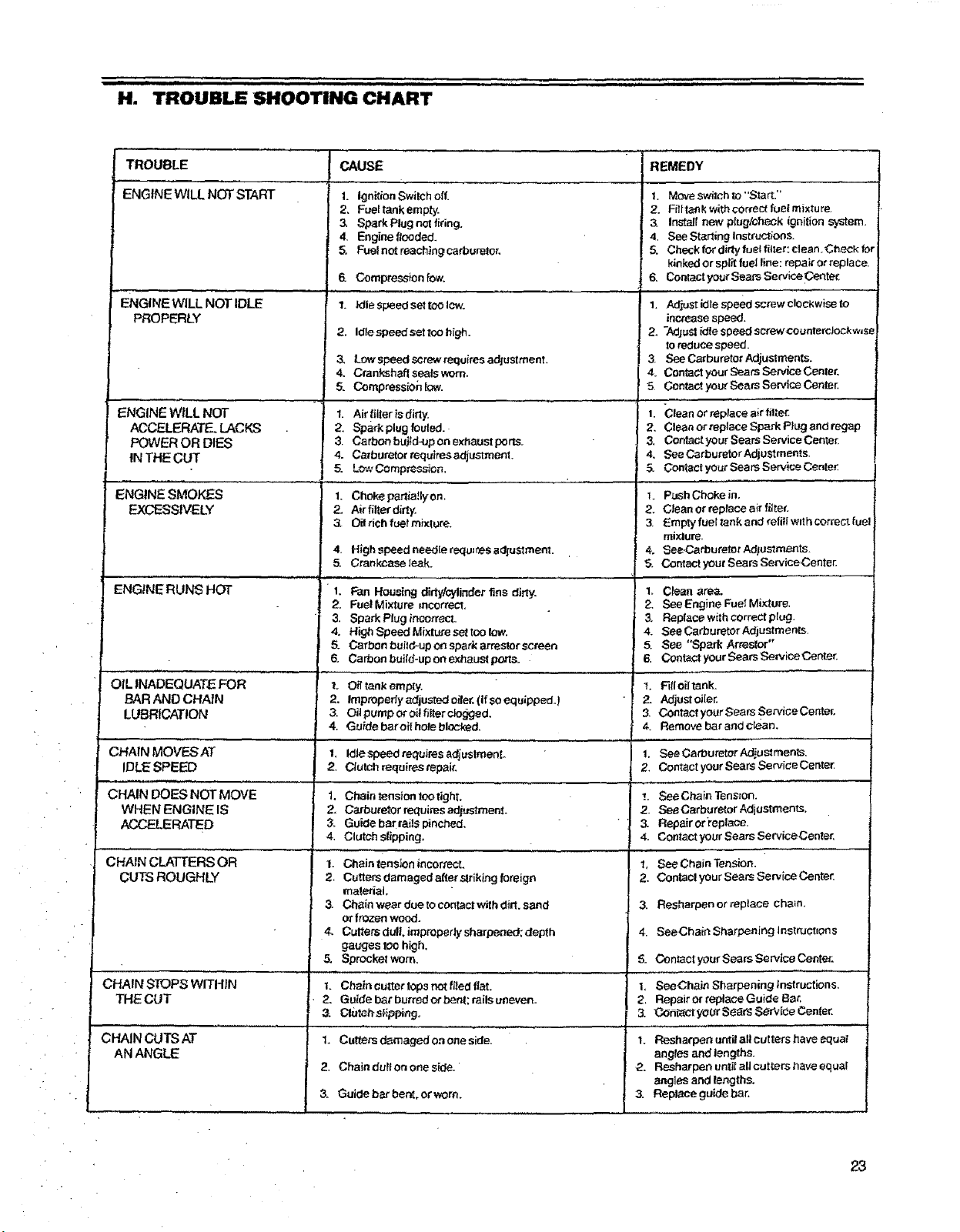

H. TROUBLE SHOOTING CHART

TROUBLE CAUSE

ENGINE WILL NOT START 1. IgnitionSwitch off.

2, Fuet tank emptt.

3. SpankPlug notfiring.

4. Engine flooded.

5. Fuelnotreaehingcarburetor,

ENGINE WILL NOT IDLE

PROPERLY

ENGINE WILL NOT

ACCELERATE. LACKS

POWER OR DIES

tN THE CUT

ENGINE SMOKES

EXCESSIVELY

ENGINE RUNS HOT

OIL INADEQUATE FOR

BAR AND CHAIN

LUBRICATION

CHAIN MOVES AT

IDLE SPEED

C INOOE;NOTMOVE

WHEN ENGINEIS

ACCELEF_TED

CUTS ROUGHLY

CHAIN STOPS WITHIN

THE CUT

......,J ...........J , ,

CHAIN CUTS AT

AN ANGLE

6. Compression few.

I. Idle Speed set too low.

2. IdleSpeedset too high.

& Lowspeed screwrequires adjustment

4. Crankshaft seals worn.

& Compressiohiow.

....., .......................w

I. Air filterisdirly.

2. Spark plugfouled.

3. Carbon build-up on exhaustports.

4. Carburetorrequiresadjustment

5. L_._;Comp,.'Cssfon,

1. Choke partia!lyen,

2, Air filter dirtF

& Oil rich fuelmixture.

4. Hi9hspeed needle requires a_us_ment

5. Crankcase ]'eak,

1. Pea Housing didyt_ylinderfins ditty.

2. Fuel Mixture incorrect

3. Spark Plug incorrect.

4. High Speed Mixture settoo low.

5. Carbon buitd-upon sparkarrestor screen

6. Carbon build-up on exhaust ports.

1. Oil tankempty.

2. Imprepedyadjustedoile_(if$oequlpped.)

3. Oi| pump oroMilter _ed,

4. Guidebaro_lholeblocked,

1. Idlespeedrequiresadjustment.

2, Clutch requires repai_.

1. Chain tensiontootight.

2, Carburetor requiresadjustment.

3. Guide bar rails pinched,

4. Clutch slipping.

1. Chain tension incur/act.

2. Curlers damaged after strikingforeign

material.

3. Chainwearduetoeontactwithdirt. sand

orfrozen wood.

4. Cuttersdulf.impropedysharpened;depth

gauges too high,

[

REMEDY

,,,,,

t. MoveSwitch to "'S_art."

2. Filltank withcOrreCtfuel mixture.

3. Installnew plugloheek ignitionsystem.

4, See Sta_ng Instructions.

5. Check for dir_.,,fuel fil_er:clean_Cheek f0

kinkedor split fuel line: repair Orreplace.

6, ContactyourSears Se_ice Center:

1, AdjuSt idle speed screw cloct_wise to

inccease speed.

2. -Adjustidlespeed screweeunterdockw=s

to reduce speed.

3. See Carburetor Adjustments,

4 Contac't yourSears Sewice Center.

5 Contactyour Sears ServiceCenter.

t "Cleanorreplacea_rfil_er.

2. Ctean or replace Spark Plug and regap

3, Contac_your Sears Service Center.

4. See C_rburetor Adjust ments.

5. ContsctyourSeareServ',,ceCente_

1. PushChoke in.

2. Clean or replace air filter.

3. Empty fuel tank and refilf withcorrect fuel

mixture.

4. See Carburetor Ad!ustments.

5. Contact your Sears ServiceCente_

I, Clean area.

2, See Engine Fue,_Mixture.

3. Replace withcorrect plug.

4. SeeCa_uretorAdjustmenEs

5. See "Spark Arrestor'"

6 Contact your Sears Se_vlCeCente_

1. FIlloiltank.

2. Adjustoiler.

3. ContactyourSearsServioeCenter.

4. Removebar and c_an.

1. Sea Ca_uretor AdjuSt meets.

2. Contact your Sears Service Cente_

1, See Chain Tenmon.

2. SeeCarburetorAdjustments.

3. Repair or'replace.

4. ContactyourSearsServiceCenter.

I, See Chain Tension,

2. Contactyour Seare Service Center.

3. Resharpen or repiace chain.

4. SeeChain Sharpening Instruct{on s

5. Sprocketworn. 5.

............... ,,, ,,

I. Chain cutter lopsnot filed flat. I,

2. Guidebarburredorbenl:railsu_even. 2.

3 Olut_l_s_i_ng, 3.

1. Cutters damaged on one side. 1.

2. Chain duffor=one side.

3. Guide bar bent, orworn.

Contactyour Sears Servlce Center.

SeeChain Sharpening Instructions.

Repair or replace Guide Bar,

C_n_et-_,._' Se_r'_SerVice Center.

Resharpen until all cutters have _='qua!

angles and lengths.

F1esharpenuntilallcuttershave equa[

angles and _engths.

Replace guide bar.

23

Loading ...

Loading ...

Loading ...