Loading ...

Loading ...

Loading ...

CUSTOMER RESPONSIBILITIES

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the grass screen;

cooling fins and other external sud&ces 0l the engine are

kept cfean at all times

Every 100 t_eursof operation (more often under extremely

dusty dirty conditions) remove the blower housing and

other cooling shrouds, Clean the cooling f ns and exlema

surfaces as necessary Make sure the cooling shrouds are

reinstalled,.

NOTE: Operating the engine with a blocked grass sci'een,

dirty or plugged coating fins, and/or cooting shrouds re-

moved wilt cause engine damage due to overheating,

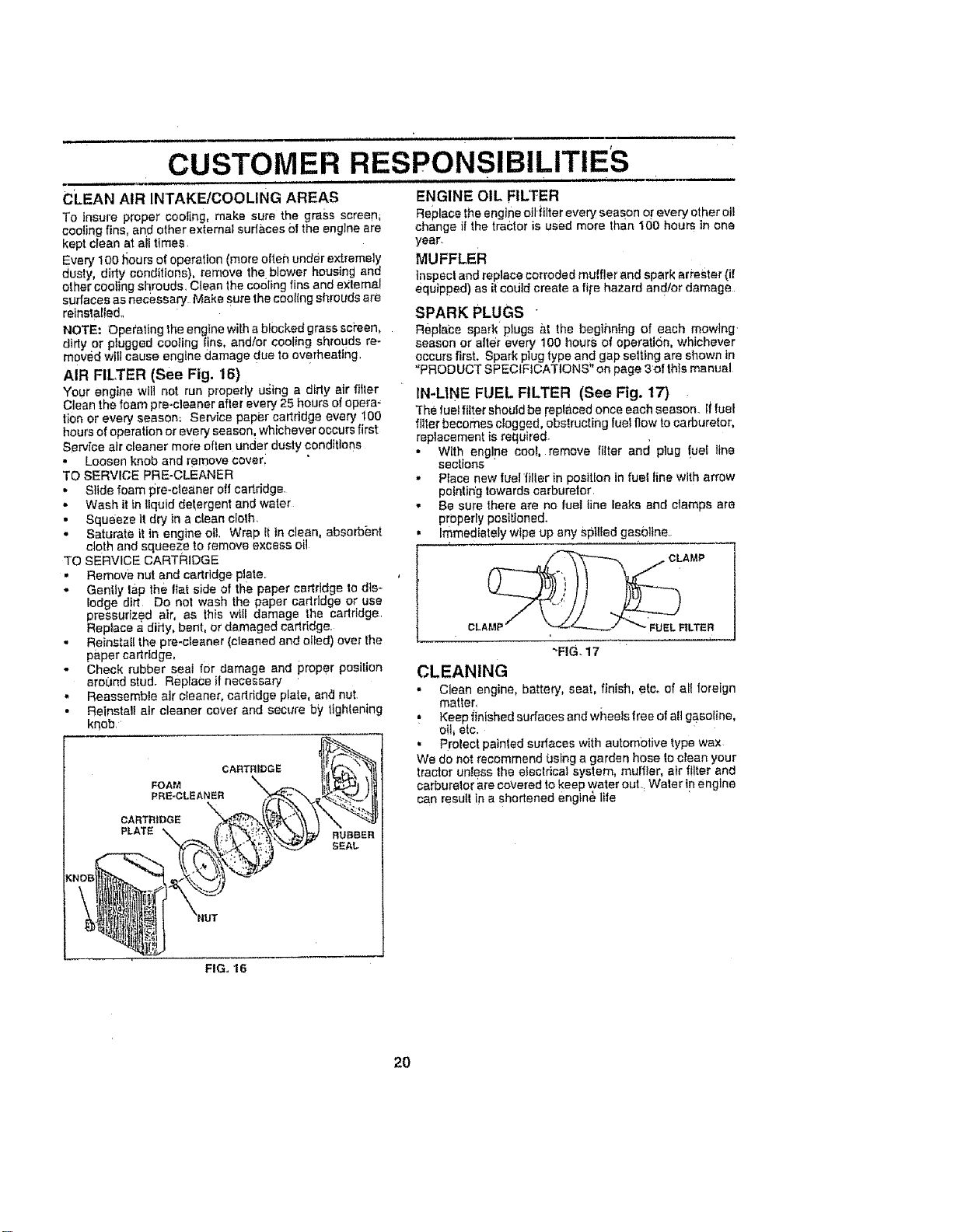

AIR FILTER (See Fig. 16)

Your engine wtil not run properly using a dirty air fit_er

Clean the foam pre-cleaner after every 25 hours of opera.

lion or every season: Service paper cartridge every 100

hours of operation or every season_ whichever occurs first

Service air cleaner more often under dusty conditions

. Loosen knob and removecover_

TO SERVICE PRE-CLEANER

, Slide foam pro-cleaner eft cartridge.

• Wash it in liquid detergent and water

• Squeeze it dry in a c_ean cloth,

• Saturate it in engine oil Wrap it in clean, absorbent

cloth and squeeze to remove excess oil

TO SERVICE CARTRIDGE

• Remove nut and cartridge plate.

• Gently tap the flat side of the paper cartridge to dis-

lodge dirt Do not wash the paper cadddge or use

pressurized air, as this will damage the cartridge

Replace a dilly, bent, or damaged cadddge.

• Reinstall the pre-cleaner (cleaned and oiled) over the

paper cartridge,

• Check rubber seal for damage and proper position

around stud. Replace if necessary

• Reassemble air c_eaner, cadddge plate, and nut.

• Reinstall air cleaner cover and secure by tightening

knob.

CARTR|DGE

FOAM

PRE-CLEANER

\

CARTRIDGE

PLATE

RUBBER

SEAL

ENGINE OIL FILTER

Replace the engine oil filter every sea_on o!"every other ol_

change il the tractor is used more than 100 hours in one

year.

MUFFLER

Inspect and replace corroded muffler and spark arrestor (if

equipped) as {tcodid create a fire hazard and/or damage

SPARK PLUGS "

ReplaCe spark plugs at the begihntng of each mewing.

season or alter every 100 hours of operation, whichever

occurs first. Spark plug type and gap setttng are shown in

"PRODUCT SPECIFICATIONS" on page 3of this manual

IN-LINE FUEL FILTER (See Fig. 17)

"_he fuel filter sheuEdbe repfaoed once each season. If fuel

_ter becomes clogged, obstructing fuel flow to carburetor,

replacement is required-

• With engine cool, remove tilter and plug !ue{ line

sections

- Place new {uel/iIler in position in fuel line with arrow

pointing towards carburetor

- Be sure there are no fuel line leaks and clamps are

property positioned.

• Immediately wipe up any spilled gas0]Ine.

-FIG. 17

CLEANING

• Clean engine, battery, seat, finish, eteo of el! loreign

matter,

• Keep f n shed surfaces and wheels free of all gasoline

oil_ etc,

• Protect painled surfaces with autombtive type wax

We do not recommend using a garden hose to clean your

tractor unless the efeclrical system, muffler, air filter and

carburalor are covered to keep water out. Water in engine

can resu{t in a shortened engln_ life

FIG. 16

2O

Loading ...

Loading ...

Loading ...