Loading ...

Loading ...

Loading ...

23

Insignia Single- and Dual-Tap Kegerator/Beverage Cooler

www.insigniaproducts.com

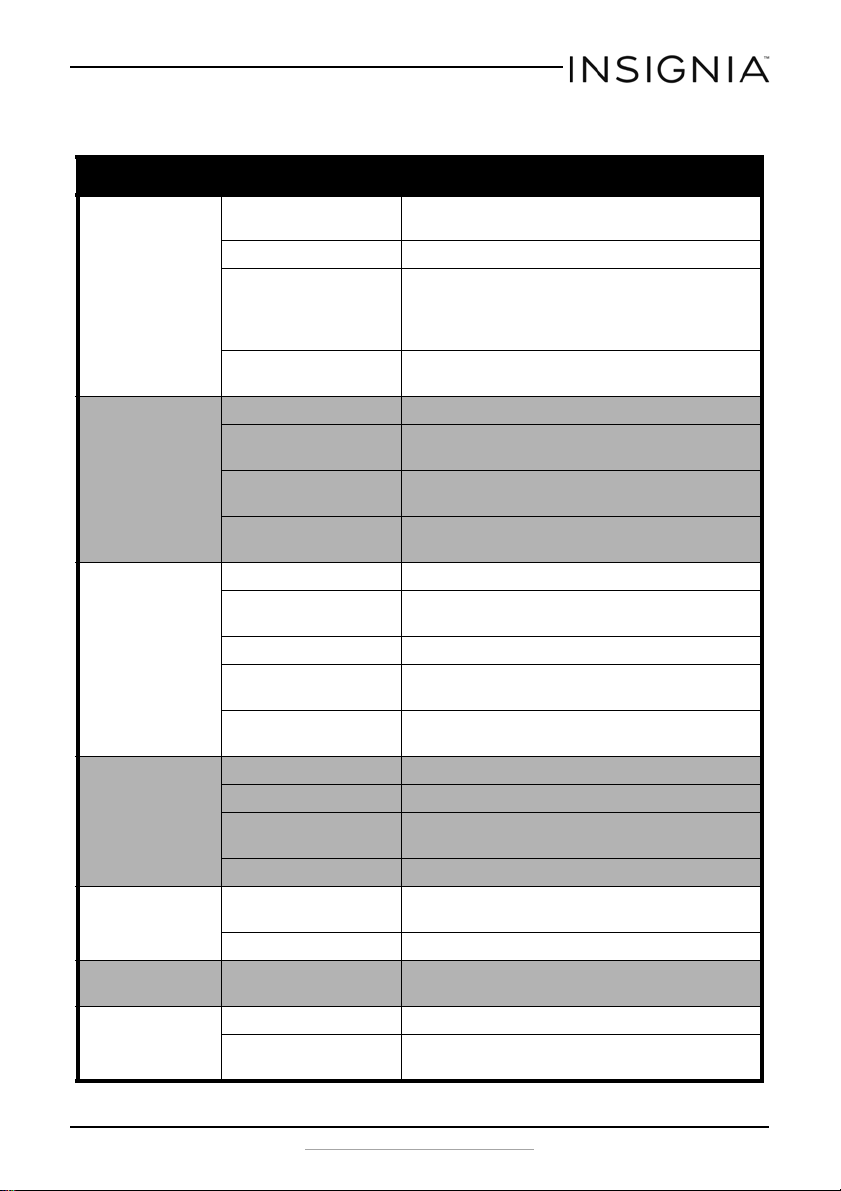

Troubleshooting - beer quality

Problem Possible cause Possible solution

Excess formation of

foam “head.” Beer is all

foam, or too much foam

and not enough liquid

beer.

Recent keg agitation. If the keg has recently been moved, let it stand a minimum of

two hours before tapping.

Improper regulator setting. Verify that the (CO

2

) pressure is reading between 10 and 12 PSI.

The Internal temperature of

the kegerator is too warm.

Make sure that the kegerator is cooling between the high 30s to

mid 40s. If the beer keg has been exposed to a warm

environment for an extended period, give it sufficient time to

cool before attempting to draw beer.

Pressure build up. Activate the pressure relief valve located on the keg coupler for

three seconds.

Flat beer - no formation

of foam. The foamy

head disappears quickly

and the beer lacks its

usual zestful brewery

fresh flavor.

Improper draw technique. See “Dispensing Beer.”

Improper regulator setting. Make sure that the (CO

2

) pressure is reading between

10 and 12 PSI.

Glassware is not clean enough. Residue on glassware in the form of oils quickly dissolves the

formation of foam. Make sure that the glassware is clean.

Dispensing hose too long. All recommended temperatures and gauge settings are

calculated for a five foot hose. Use a shorter hose.

No beer flow from the

beer faucet.

Low/Empty CO

2

tank. Make sure that the CO

2

tank has pressure.

Closed CO

2

valve and/or

shutoff valve.

Make sure that both the CO

2

tank and regulator shutoff valve

are open.

Empty beer keg. Replace beer keg.

Line or dispenser obstructions. Verify that there are no kinks or obstructions in either the air

line or the dispenser line and that neither are frozen.

Improper connections(s). Make sure that all connections are secure and all seals are in

place and in good condition.

Sputtering draw. System requires cleaning. See “Maintaining your kegerator/beverage cooler.”

Keg tap installed incorrectly. Check seal between the keg the faucet.

Obstructions in the line or

dispenser.

Verify that there are no obstructions in either the air line or

dispenser line and that neither are frozen.

Improper draw technique. See “Dispensing Beer.”

Faucet dripping. Handle not fully returned to

close position.

After every pour, make sure that the handle is returned to the

off position.

Faucet requires cleaning. See “Maintaining your kegerator/beverage cooler.”

Rapid CO

2

tank

discharge.

Improper connection causing

an air line leak.

Make sure that all lines are properly connected and/or check air

line for possible leaks.

Difficulty manipulating

faucet handle.

Faucet requires cleaning. See “Maintaining your kegerator/beverage cooler.”

Damaged faucet handle. Remove the faucet handle and connector nuts and inspect for

possible damage.

Loading ...

Loading ...

Loading ...