Loading ...

Loading ...

Loading ...

7

W415-0764 / C / 11.19.13

EN

The 1101 insert must be installed into a solid fuel burning fi replace that is at least 16 1/2” (419mm) deep, 28 1/2"

(724mm) wide and 22" (559mm) high with an approved lined chimney at least 15' (4.6m) high and a hearth of 16”

(406mm).

Your 1402 insert must be installed only into a solid fuel burning fi replace that is at least 14 1/2" (368mm) deep 26"

(660mm) wide and 22" (559mm) high with an approved lined chimney at least 15' (4.6m) high and a hearth of 16”

(406mm). This minimum recess can only be achieved if the opening height is suffi cient enough to allow the connector

to fi t under the noncombustible facing. The appliance and chimney must be constructed in accordance with all national

and local building code standards.

The chimney vent system used on your wood burning appliance should be designed with the least amount of

restriction possible to enable the exhaust products to easily fl ow through it. Chimney vent systems that are too

short or too long can also have an adverse affect on the fl ow of exhaust through it. The wood burning appliance

and chimney vent system also require a suffi cient supply of combustion air not only to support the combustion in the

combustion chamber but to replace the exhaust leaving it so it can fl ow freely up through the vent system and out

into the atmosphere. It is the correct balance of combustion air and the chimney vent system that will ensure the

appliance provides you with its optimum performance.

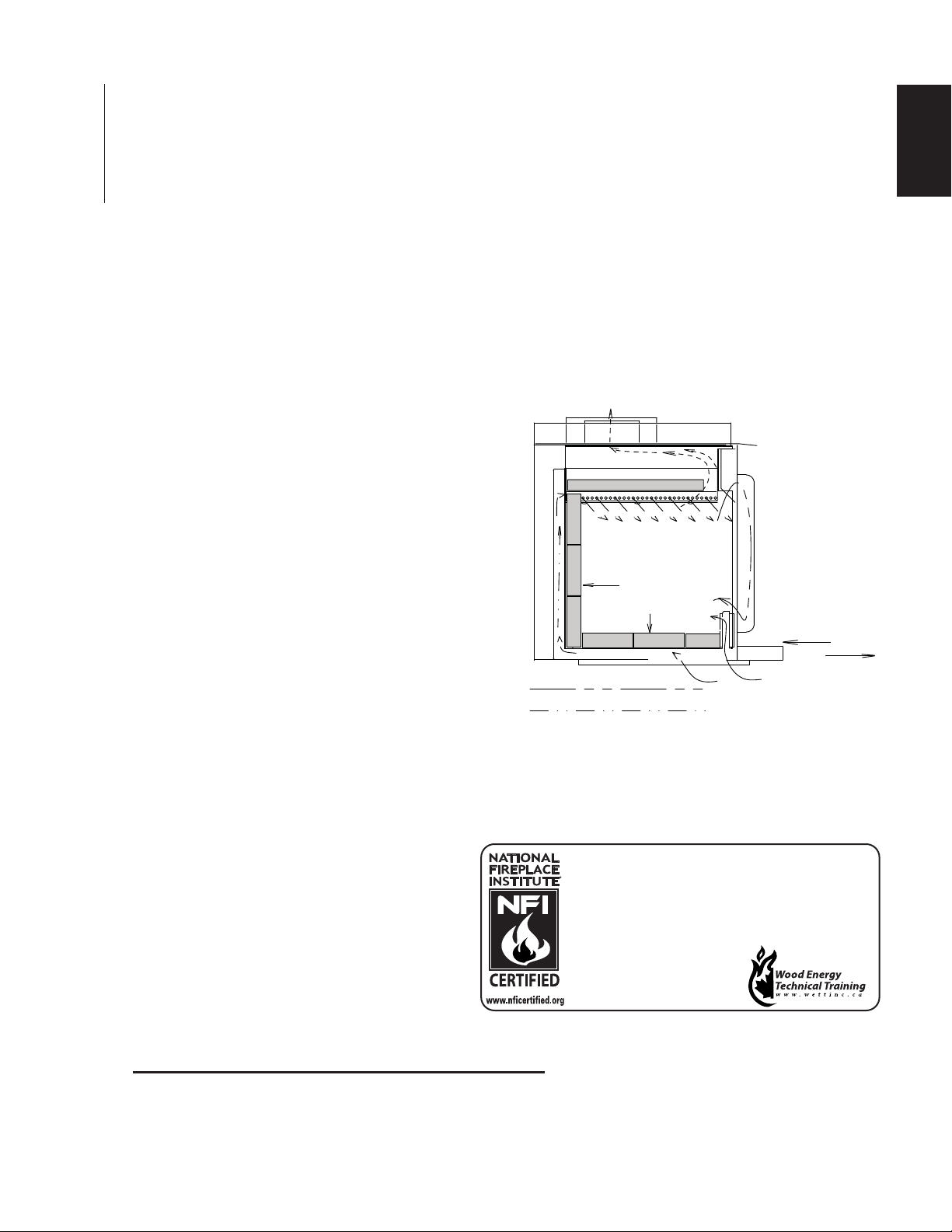

Combustion air enters through two holes in the bottom covered by a single draft control. Air from the front

hole goes up on either side of the door into a preheating

airwash located across the top and then down the

window to feed the fi re and also to ensure that the glass

remains clean. Air from this hole also feeds directly into

the combustion chamber at hearth level. Secondary air

from the rear hole travels up the back in the secondary

air housing to the manifold located at the top and shoots

out laterally to oxidize the gases below the smoke exit.

The combustion chamber is lined with high temperature

fi rebrick on 2 sides, the back and across the bottom,

with a layer of fi bre baffl es at the top to maintain a

high temperature in the combustion chamber so that

gases mixing with the preheated air from the secondary

air manifold tube are easily ignited and burned. The

appliance sides and back are shielded to direct the heat

upwards and forwards into the room.

Be sure to provide suffi cient combustion air. There are

many other appliances in your home competing for air

such as: a kitchen range hood, forced air heating devices or a bathroom exhaust fan.

Expansion / contraction noises during heating up and cooling down cycles are normal and to be expected.

After extended periods of non-operation such as following a vacation or a warm weather season, the appliance

may emit a slight odour for a few hours. This is caused by dust particles on the fi rebox burning off. Open a

window to suffi ciently ventilate the room.

CALIFORNIA PROP 65 WARNING:

Use of this product may produce smoke which

contains chemicals known to the State of

California to cause cancer, birth defects, or other

reproductive harm.

If you experience smoking problems, you may

need to open a door, a window or otherwise

provide some method of supplying combustion

air to the appliance.

HINT FOR INSTALLING PORCELAIN ENAMEL INSERTS:

Ensure the base of the porcelain side panels are protected from rubbing against the hearth when sliding your

insert into the masonry fi replace.

HOT SECONDARY AIR

FIBRE BRICKS

REFRACTORY

2 SIDES, BACK

& BOTTOM

SECONDARY AIR

PRIMARY AIR

FLUE GLASS

CERAMIC

GLASS

AIR CONTROL

COMBUSTION AIR

INTAKE

OPEN

CLOSED

We suggest that our woodburning hearth products

be installed and serviced by professionals who are

certified in the U.S. by the National Fireplace

Institue® (NFI) as NFI Woodburning Specialists or

who are certified in Canada by

Wood Energy Technical

Training (WETT).

Loading ...

Loading ...

Loading ...