Loading ...

Loading ...

Loading ...

should be at least 2 inches of clearance between the chimney and floor joists or other com-

bustible materials. Poor flashing between the chimney and the roofline can cause leaks and

deterioration of chimney mortar.

You should make preliminary checks, but if you have any doubts, or are unfamiliar with

chimney construction, cleaning, or maintenance, have a local fire official or certified chimney

professional inspect your chimney. If repairs are required, be sure to use someone who is

knowledgeable in chimney work and familiar with local code requirements.

In addition: All brick or cinder block chimneys should have clean out access with a tightly fit-

ting door. Masonry chimneys should have a wash at the top. All chimneys should have a cap to

keep out rain and snow and to minimize downdrafts caused by wind.

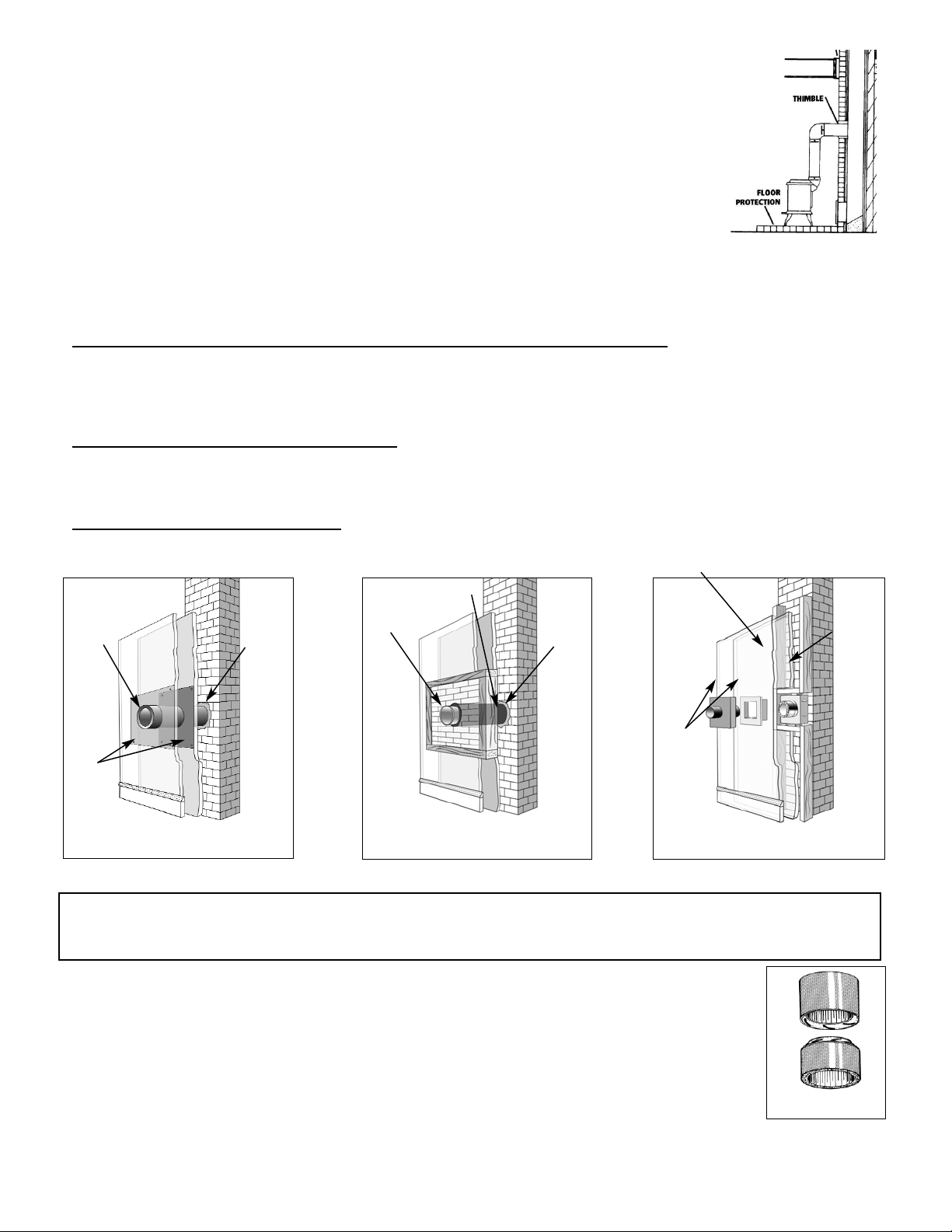

Passing Through A Combustible Wall:

With an exterior chimney, in most cases the chimney connector (or stove pipe) will need to pass through a combustible

wall. The following are acceptable methods:

A.

Use a section of Solid Insulated Prefabricated Metal Chimney to connect to the chimney - Use a section of insulated

prefabricated 2100° Class A chimney pipe listed to UL 103 HT (at least 1” of insulation or greater) the same inside diameter

as the stove pipe and maintain a 9” air space between the wall of the prefabricated chimney and the combustible wall. This

section of chimney pipe can be supported by a sheet metal plate securely fastened to the combustible wall, with a hole cut in

the middle of it. This will close the gap around the chimney pipe and the framed opening. (See Diagram A Below)

B. Build a solid brick surround around a tile liner - Frame a 3.5” thick brick surround into the combustible wall you need to

pass through. Maintain a minimum 12” brick separation from the clay liner to combustibles. The minimum 5/8” thick clay

liner should be cemented in place and run from the outer surface of the brick to the inner surface of the chimney. (See

Diagram B Below)

C.

There are also UL Listed kits available that are specifically designed for passing through a combustible wall. For more

information on these kits, please contact Woodstock Soapstone Company. Please note: there are several UL listed wall pass

through kits available, always follow the specific manufacturers installation instructions. (See Diagram C Below)

For other methods, please refer to NFPA 211.

REMEMBER, UNPROTECTED SINGLE OR DOUBLE WALL STOVE PIPE SHOULD NOT PASS THROUGH A

COMBUSTIBLE WALL OR CEILING TO CONNECT TO THE CHIMNEY. YOU MUST USE AN APPROVED METHOD

WHICH PROVIDES GREATER PROTECTION THAN SINGLE OR DOUBLE WALL PIPE.

Prefabricated Metal Chimneys:

For high efficiency, freestanding woodstoves, like your Woodstock Soapstone stove, a Prefabricated

Metal Chimney must be listed as Class A and carry a UL Listing of 103 HT (high temperature). The “UL

103 Type HT Class A” prefabricated chimney will have a temperature rating of 2,100° F.

There are prefabricated chimney systems that are approved only to 1,700° F and are suitable only for

fireplace inserts or factory built fireplaces. DO NOT use these with your Woodstock Soapstone stove.

At the point of the first penetration of a combustible surface (i.e., wall or ceiling) all subsequent

venting components need to be prefabricated “UL Type HT Class A”. If your prefabricated chimney

Connecting your stove to a

masonry thimble.

The minimum clearance for a single wall

metal stovepipe and terra cotta thimble at the

chimney connection is 12”

A.

Using a Prefabricated Metal Chimney section

to connect to an existing masonry chimney

located behind a combustible wall

Use a UL listed and approved wall pass thru kit.

B.

Refractory

Cement

Insulated

section of

factory built

chimney

Sheet

Steel

Supports

9”

9”

9”

9

Refractory

Cement

Fireclay Thimble

12”

12”

12”

12

Stainless Steel

Connector

C.

UL listed

insulated

thimble

Minimum required

air space

Listed wall

protector &

cover shield

UL 103 HT Stainless

Chimney Connection

3

Loading ...

Loading ...

Loading ...