Loading ...

Loading ...

Loading ...

The Ideal Steel Hybrid Combustion System Explained

The Woodstock Soapstone Company’s tradition of build-

ing high quality, dependable wood stoves continues in the

Ideal Steel Hybrid Wood Stove. This new design combines

modern technology to achieve clean and efficient heating

performance with rugged reliability and affordable steel con-

struction.

While the Ideal Steel Hybrid shares some time tested fea-

tures with other members of the Woodstock Soapstone fami-

ly, it also includes some features that are unique. The Ideal

Steel Hybrid has a large glass front that benefits from our

proven air-wash design, but unlike our other wood stoves,

the glass front is also a large loading door. The door swings

open wide for access to a large firebox which can be loaded

front-to-back or side-to-side, depending on the length of your

wood. Innovative andirons protect the glass and can fold out

of the way when the door is opened for loading. The firebox

can be lined with thick soapstone panels or firebrick, and the

exterior is plate steel in order to make the Ideal Steel Hybrid

more affordable.

The Ideal Steel Hybrid has a hybrid combustion system

similar to the one that we pioneered in our Progress Hybrid

wood stove. The combination of the catalytic combustor and

the secondary combustion system gives the operator a wide

range of heat output while maintaining a clean and efficient

burn. In addition to the Hybrid combustion design, the Ideal

Steel Hybrid incorporates new automatic catalyst air to opti-

mize the catalytic combustor’s effec-

tiveness.

Hybrid burn technology

improves efficiency, lowers emis-

sions, and allows for a wider range

of output to meet the heating needs

of the operator. Hybrid stoves from

Woodstock combine the best attrib-

utes of both catalytic combustors and

secondary combustion systems. A

brief description of each is below, fol-

lowed by a more detailed explana-

tion.

Catalytic Combustion:

• Burns woodstove exhaust gases

starting at 500

O

F

• Operates best at low to moderate

burn rates

• Typically yields long duration burns

that are clean and efficient

• Improves stove efficiency by

generating heat from burning

wood smoke

Secondary Combustion:

• Burns woodstove exhaust gases

starting at approximately 1000

O

F

• Operates best at moderate to

high burn rates

• Creates hot firebox for maximum heat output

• Provides a very active fire that is great for viewing

Catalytic combustors are well suited for very long burn

cycles. Catalytic combustors have the ability to reduce or

eliminate woodstove pollution at low stack temperatures.

This means much cleaner, more efficient burns at low firing

rates than is possible without a catalyst. The catalytic reaction

eliminates harmful combustion byproducts and converts

exhaust to water vapor and carbon dioxide. The catalytic

combustor burns exhaust gasses and converts them to heat,

which is captured inside the stove. This extra heat increases

the overall efficiency and output of a catalytic wood stove.

The combustor takes full advantage of the energy in wood

smoke that would otherwise be lost up the chimney as pollu-

tion and wasted energy at low burn rates.

Secondary combustion systems are designed to maximize

efficiency and reduce emissions as well, but they operate dif-

ferently. The secondary combustion system introduces sec-

ondary air in the firebox to ignite the volatile gases produced

by the burning wood. This reaction requires temperatures

over 1000 degrees F to start breaking down the organic com-

pounds in the wood smoke. Secondary combustion systems

work best when the stove has high firebox temperatures and

secondary combustion air introduced into the high tempera-

ture area at the top of the firebox. With secondary combus-

tion the exhaust gases burn at very high temperatures before

leaving the firebox, providing an unusual display of second-

ary flames in the top of the firebox.

In addition to primary and secondary air, the

Ideal Steel Hybrid incorporates a system to intro-

duce air directly to the catalytic combustor as it

heats up. When the catalyst is fully engaged a self

adjusting, bimetallic coil opens a small damper to

allow heated air into the exhaust path just

upstream from the combustor. This dedicated “cat-

alyst air” keeps the combustor active and helps

control primary and secondary burn rates. As the

stove and chimney heat up and draft is increased,

more catalyst air is added automatically. This has

the effect of stabilizing primary and secondary air

and at higher temperatures will actually reduce

primary and secondary air. The catalyst air design

acts similar to a barometric damper.The catalyst air

improves emissions and efficiency at high burn

rates, provides overfire protection, and stabilizes

the burn rate- automatically.

These systems are not mutually exclusive and

have been designed to work together. The Ideal

Steel Hybrid is designed to utilize each system

depending on the conditions present in the fire-

box. This makes operating the Ideal Steel Hybrid

as simple as possible while providing a clean and

efficient burn over a wider range of heat output.

The Ideal Steel Hybrid wood stove. The perfect

combination of affordability, innovative combus-

tion technology, and rugged construction.

INTRODUCTION

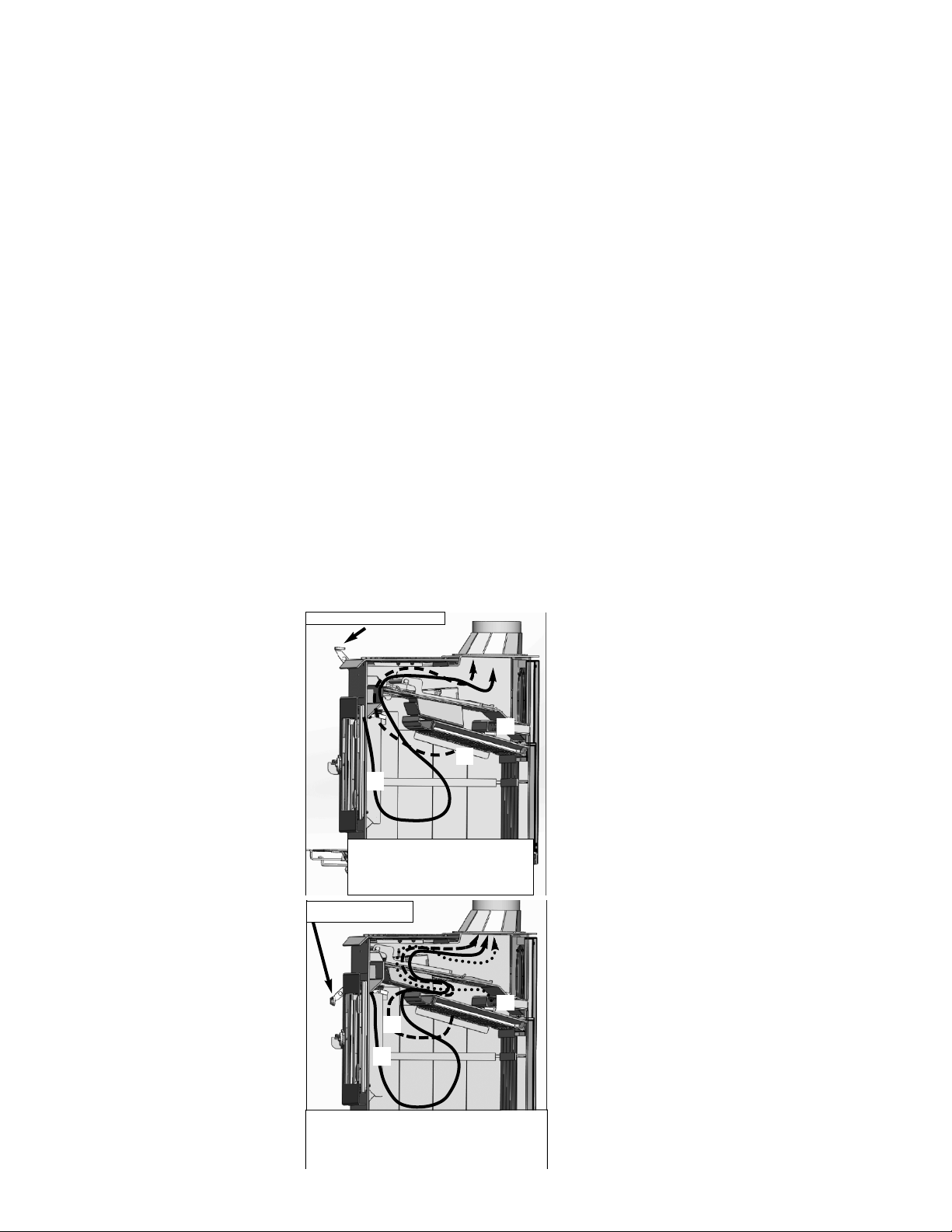

Catalytic bypass open

Three sources of combustion air:

1. primary air,

2. secondary air, and

3. catalyst air

1

2

Catalytic bypass closed

(combustor engaged)

1

2

3

Once the catalytic combustor is engaged,

smoke from the primary & secondary burn

will be directed through the catalytic com-

bustor. The catalyst air will help keep the

combustor operating at peak efficiency.

3

Loading ...

Loading ...

Loading ...