Loading ...

Loading ...

Loading ...

F, S__IE NOTE: If you do not want to remove the fuel from

d_ CAUTION

It is important to prevent gum deposits from

tbrming in essential fuel system parts such as the

carburetor, fuel filter, fuel hose, or fuel tank dur-

ing storage. Experience indicates that alcohol

blended fuels (called Gasohol or using ethanol or

methanol) can attract moisture which leads to

sepal_tion and tbrmation of acids during storage°

Acidic gas call damage the fuel system of an

engine while in storage.

1° Allow the engine to cool, empty the fuel system, and

secure the tool before transporting or storing.

2. Before storing the too!, use up fuel left in the fuel lines

and carburetol by starting the engine and letting it run

until it stops_

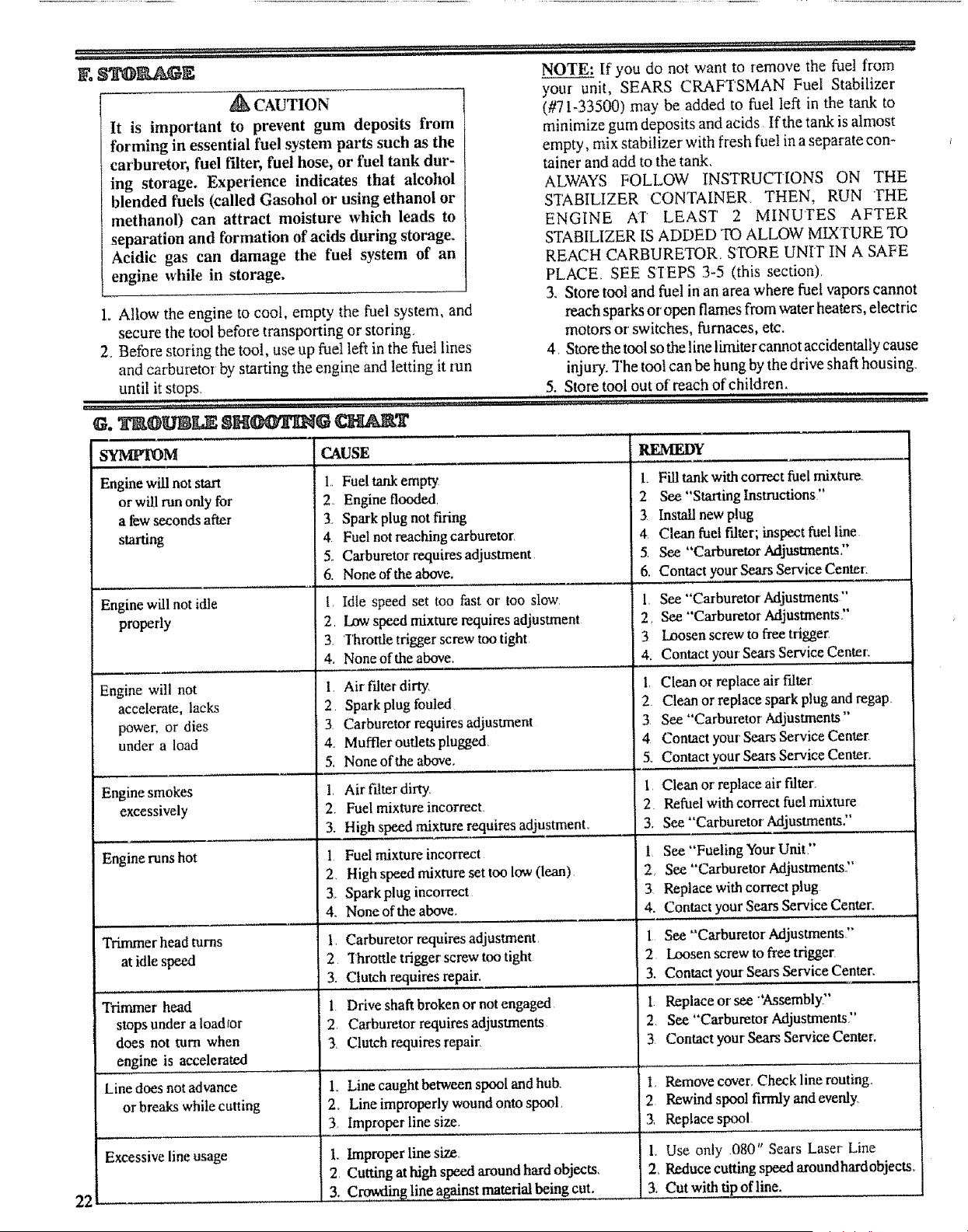

@.'_OUBg2_: 8H_@ _'gART

_M

Engine will not start

orwill run only for

a fewseconds after

starting

Engine will not idle

properly

.

Engine will not I.

accelerate, lacks 2

power; or dies 3

under a load 4.

5,

Engine smokes 1.

excessively 2

3.

Engine runs hot 1

2.

3.

4.

..........,H, , .........

Trimmer head turns 1.

at idle speed 2

3.

'It'immer head 1

stops under a Ioadfor 2

does not turn when 3

engine is accelerated

Line does not advance L

or breaks while cutting 2.

3.

your unit, SEARS CRAH'SMAN Puel Stabilizer

(#71-33500) may be added to fuel left in the tank to

minimize gum deposits and acids If the tank is almost

empty, mix stabilizer with fresh fuel in a separate con-

tainer and add to the tank,

ALWAYS tZOLLOW INSTRUC'HONS ON THE

STABILIZER CONTAINER THEN, RUN THE

ENGINE AI LEAST 2 MINUI'ES AFTER

STABILIZER IS ADDED TO ALLOW MIXTURE TO

REACH CARBURETOR. STORE UNIT IN A SAlZE

PLACE. SEE SIEPS 3-5 (this section)

3. Store tool and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc.

4, Store the tool so the line limiter cannot accidentally cause

injury. The tool can be hung by the drive shaft housing.

5. Store tool out of reach of children.

qJ ........ .i.q uJ 11 /[I,I.IJJHJ H .................

!CAUSE ........................

1.. Fuel tankempty

2.. Engine flooded

3_ Spark plug not firing

4 Fuel not reaching carburetor_

5. Caxburetor requires adjustment

6. None ofthe above.

1. Idle speed set too tast or too slow

2. Low speed mixture requires adjustment

3 Thronle trigger screw too tight

None of the above. 4.

Air filter dirty_ 1,

Spark plug fouled 2

Carburetor requires adjustment 3

Muffler outlets plugged, 4

None of the above. 5.

Air filter dirty. 1

Fuel mixture incortect. 2

High speed mixture requires adjustment. 3.

H,, ...., H, .,.,,H ......

Fuel mixture incorrect 1

High speed mixture set too low (lean). 2_

Spark plug incorrect 3

None of the above. 4.

Carburetor requires adjustment, I

Throttle trigger screw too tight 2

Clutch requires repair. 3.

i i t t .... tilt ,lltjt ......

Drive shaft broken or not engaged I

Carburetor requires adjustments 2,

Clutch requires repair. 3

Line caught between spool and hub. I.

Line improperly wound onto spool. 2

Improper line size. 3

REMEDY

L

2

3

4

5.

6.

l

2

3

,, ,,,,,,

Fill tank with correct fuel mixture,

See "Starting Instructions"

Install new plug

Clean fuel fdter; inspect fue! line

See "Carburetor Adjustments?'

Contact your Sears Service Center,

See "Carburetor Adjustments "'

See "'Carburetor AdjustmentsT'

Loosen screw to flee trigger

C0nta.c!..yourSears Service Cenmr.

Clean or replace air fdter

Clean or replace spark plug and regap

See "Carburetor' Adjustments"

Contact your'Sears Service Center

Contact your Seats Service Center.

Clean or' replace air fdter.

Refuel with correct fuel mixture

See "Carburetor Adjustments."

See "Fueling Your Unit"

See "Carburetor Adjustments.."

Replace with correct plug.

Contact your Sears Service Center.

See "Carburetor Adjustments"

Loosen screw to free trigger

Contact your Sears Service Center.

Replace or see "'Assembly?'

See "Carburetor Adjustments."

Contact your Sears Service Center.

Remove cover..Check line muting.

Rewind spool firmly and evenly.

Replace spool

22

Excessive line usage L Improperline size,

2, Cutting at high speed around hard objects,

3, C_,_g line against matedai being cut.

k Use only 080" Sears Laser Line

2, Reduce cutting speed aroundhardobjects..

3, Cut with tip of line.