Loading ...

Loading ...

Loading ...

TO CLEAN BATTERY AND TERMINALS

Co rrosion and dtrton the battery and terminals

can cause the battery to "leak" power.

1. Remove temlinal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

3. Rinse the battery w_th plain water and

dry.

4. Clean terminals and battery cable ends

wIth wire brush until bright.

5. Coat terminals with grease or petroleum

ielly.

6. Remstalf battery (See "REPLACING

BATTERY" in the Service and Adjust-

ments section of this manuall.

TRANSAXLE MAINTENANCE

Keep transaxle free from bu_ld-up of dirl and

chaff wh=ch can restrict cootng.

Do not attempt to clean transaxle while

engine is running or while the transaxle {s

hot. To prevent possible damage to seals,

do not use high pressure water or steam to

clean transaxle.

V-BELTS

Check V-baits for deterioration and wear after

t00 hours of operation and replace ifneces-

sary. The belts are net adjustable, Replace

belts _fthey begin to slip from wear.

ENGINE

LUBRICATION

Only use high quality detergent eelrated with

API servtce classification SG-SL. Seiectthe

oil's SAE viscosity grade according to your

expected operat=ng temperature,

I__ I SAE VfSCOSITI GRADES

J

NOTE: Although mulh-wscoslty ells (5W30.

10W30 etc.) treprove starttng Er_coId weather

they will result in increased oil consumption

when used above 32_F/0°C. Check your

engine oit level more frequentiyto avoid pos-

sible engine damage from runntng low on oil.

Changethe eit after every 50 hours of opera-

tton or at least once a year If the tractor is

not used for 50 hours _none year.

Check the crankcase otl level before starting

the engine and after each eight (8) hours

of operation. Tighten oil flit cap/dipshck

securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL,

• Be sure tractor is on level surface.

• QEIwill drain more freely when warm,

• Catch eel in a sultab{e container.

1 Remove oil fill capidipsttck, Be careful

not to allow dirt to enter the engine when

changing oil.

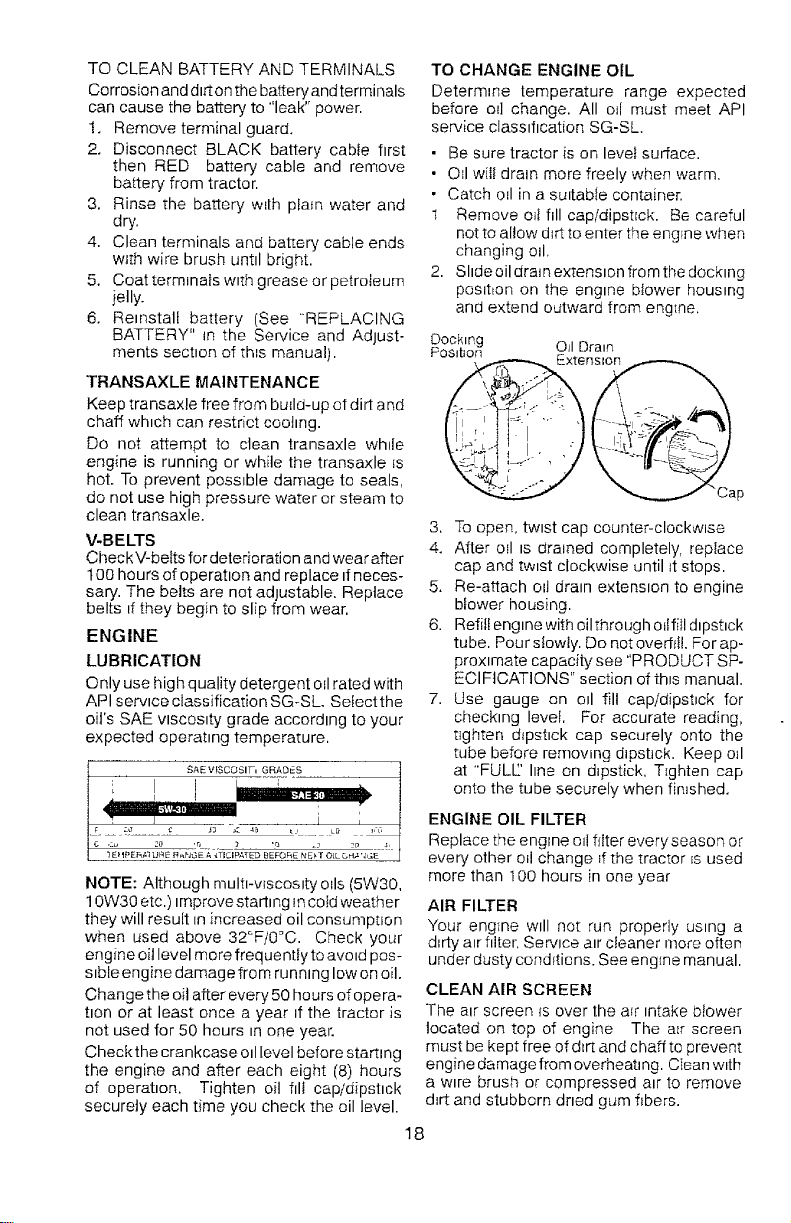

2. Shdeoil dram extension from the dock_ng

pos_t_on on the engtne blower housing

and extend outward from engtne,

Docking

Posit{on Oii Dratn

Extension

Cap

3, To open, twist cap counter-clockwise

4. After oil ts drained completely, replace

cap and twist clockwise until it stops.

5, Re-attach oil drain extension to engine

blower housing.

6. Refilt engtne with oil through o_Ifill dtpst_ck

tube. Pour slowly. Do not overNi. For ap-

proximate capacity see "PRODUCT SP-

ECIFICATIONS" section of this manual.

7. Use gauge on oil fill cap/dipstick for

checktng level. For accurate reading,

tighten d_pshck cap securely onto the

tube before removing dipstick. Keep o_1

at "FULE' line on d_pstick. T_ghten cap

onto the tube securely when finished,

ENGINE OIL FILTER

Replace the engine od filter every season or

every ether od change _f[he tractor _sused

more than 100 hours in one year

AIR FILTER

Your engine w=ll not run properly using a

d_rtya_rNter, Service atr cteaner more often

under dusty cendftions. See engine manual.

CLEAN AIR SCREEN

The a_rscreen _sover the a_r _ntake blower

located on top of engine The azr screen

must be kept free of d_r[ _nd chaff to prevent

engine damage from overheating. C{ean w_th

a w_re brush or compressed air to remove

d_rt and stubborn dned gum fibers.

18

Loading ...

Loading ...

Loading ...