Loading ...

Loading ...

Loading ...

5. HEALTH AND SAFETY INFORMATION

- 6 - - 19 -

10. TROUBLESHOOTING

5.1 GENERAL SAFETY INSTRUCTIONS FOR POWER TOOL USE

When using any type of power tool there are steps that should be taken to make sure that you, as

the user, remain safe.

Common sense and a respect for the tool will help reduce the risk of injury.

Read the instruction manual fully. Do not attempt any operation until you have read and

understood this manual.

Most important you must know how to safely start and stop this machine, especially in an

emergency.

Keep the work area tidy and clean. Attempting to clear clutter from around the machine during

use will reduce your concentration. Mess on the floor creates a trip hazard. Any liquid spilt on the

floor could result in you slipping.

Find a suitable location. If the machine is floor mounted; the location should provide good

natural light or artificial lighting as a replacement. Avoid damp and dust locations as it will have a

negative effect on the machine’s performance.

If the machine is portable; do not expose the tool to rain. In all cases do not operate power tools

near any flammable materials.

Beware of electric shock. Avoid contact with earthed surfaces; because they can conduct

electricity if there is an electrical fault with the power tool. Always protect the power cable and

route it away from danger.

Keep bystanders away. Children, onlookers and passers by must be restricted from entering the

work area for their own protection. The barrier must extend a suitable distance from the tool user.

Unplug and house all power tools that are not in use. A power tool should never be left

unattended while connected to the power supply. They must be housed in a suitable location,

away locked up and from children.

Do not overload or misuse the tool. All tools are designed for a purpose and are limited to what

they are capable of doing. Do not attempt to use a power tool (or adapt it in any way) for an

application it is not designed for. Select a tool appropriate for the size of the job. Overloading a

tool will result in tool failure and user injury: This covers the use of accessories.

Dress properly. Loose clothing, long hair and jewellery are all dangerous because they can

become entangled in moving machinery: This can also result in parts of body being pulled into the

machine.

Clothing should be close fitted, with any long hair tied back, jewellery and neck ties removed.

Footwear must be fully enclosed and have a nonslip sole.

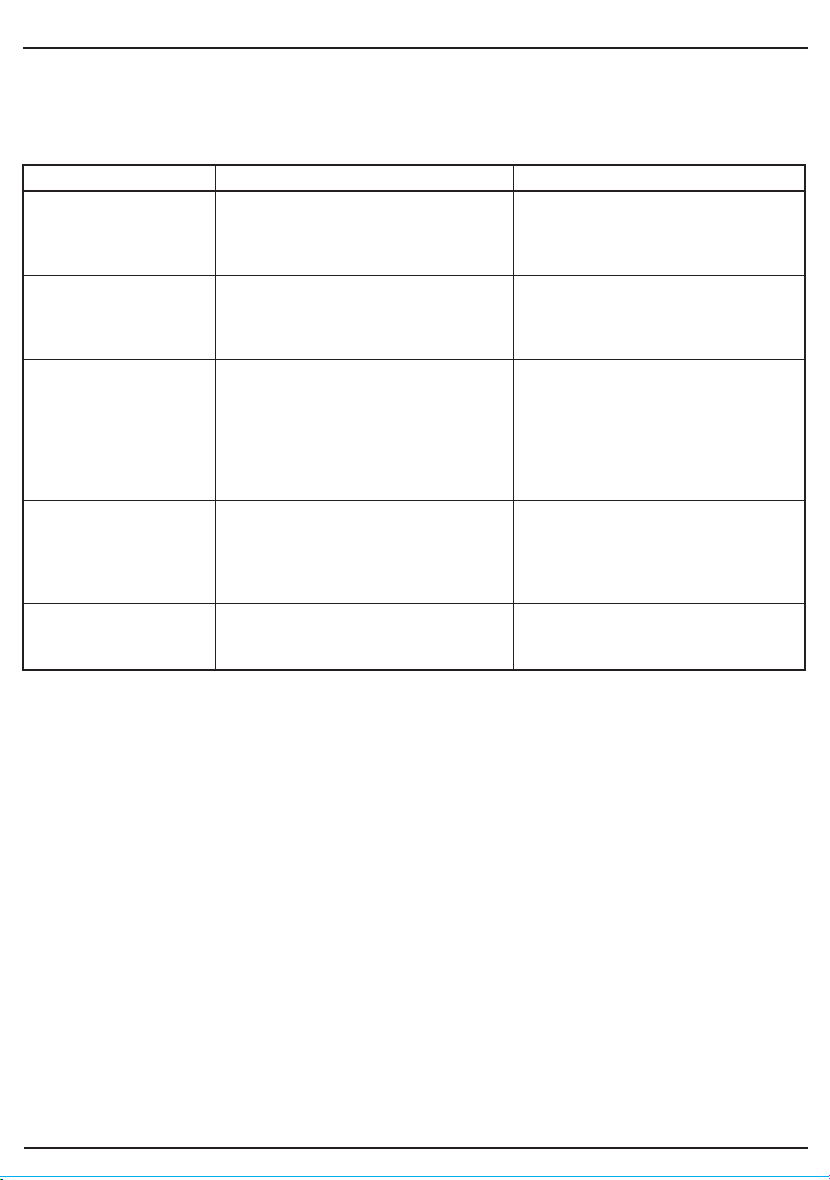

Machine will not start.

1. Fuse.

2. Other.

1. Replace/reset time delay fuse or

circuit breaker.

2. Return to an authorised service

agent for diagnosis.

Noisy operation.

Problem Cause Remedy

1. Incorrect belt tension.

2. Dry spindle.

3. Loose spindle pulley or motor pulley.

1. Adjust tension.

2. Lubricate spindle with grease.

3. Tighten set screws in pulleys.

1. Incorrect speed.

2. Swarf not coming out of hole.

3. Blunt bit.

4. Feeding too slow.

5. Not lubricated.

1. Change speed.

2. Retract bit frequently to clear swarf.

3. Sharpen or replace bit.

4. Feed fast enough to allow drill to

cut.

5. Lubricate bit.

1. Bent bit.

2. Worn spindle bearings.

3. Bit not properly installed in chuck.

4. Chuck not properly installed.

1. Use a straight bit.

2. Return to an authorised service

agent.

3. Install bit centrally.

4. Refit chuck properly.

1. Workpiece pinching bit or excessive

feed pressure.

2. Improper belt tension.

1. Support or re-clamp workpiece.

2. Adjust tension.

Bit burns or smokes.

Excessive drill run-out

or wobble.

Drill binds in workpiece.

10.1 TROUBLESHOOTING

WARNING: For your safety always turn the main switch on the machine "off" and remove the plug

from the power supply before carrying out any maintenance or trouble shooting.

Loading ...

Loading ...

Loading ...