Loading ...

Loading ...

Loading ...

9. SETTING THE BENCH DRILL

6. TECHNICAL DESCRIPTION

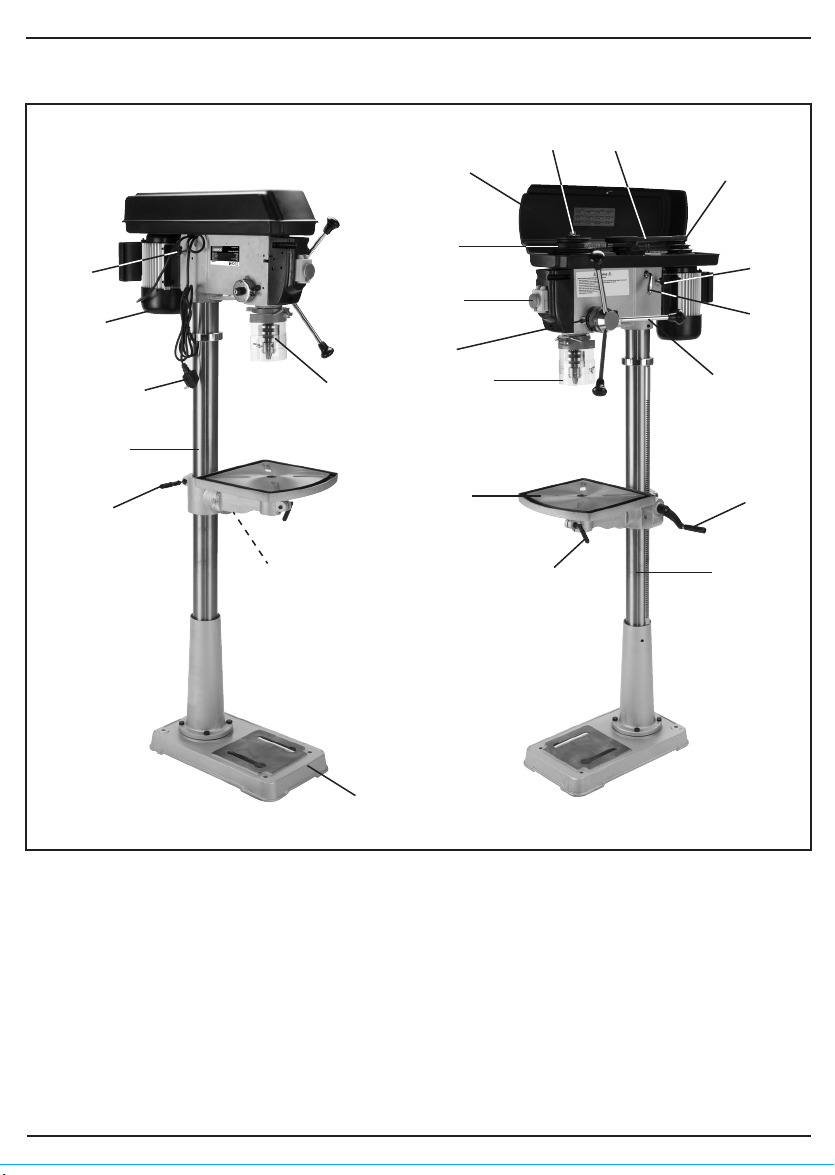

6.1 IDENTIFICATION

- 10 - - 15 -

Pulley cover.

Spindle.

Intermediate pulley.

Motor pulley.

Motor tension locking

knob.

Motor tension lever.

Plunge handle.

Table height crank

handle.

Rack.

Table locking handle.

Work table.

Guard assembly.

No-volt on/off switch.

Spindle pulley.

Geared chuck.

Work table tilt locking

bolt.

Base.

Moulded plug & cable.

Work table height/

rotation locking handle.

Column.

Depth stop.

Motor.

Motor tension locking

knob.

FIG.13

FIG.12

NOTE: Remove the plug from the socket before

carrying out adjustment, servicing or maintenance.

9.1 SPINDLE SPEED

ADJUSTMENT - FIGS. 14 - 17

This drilling machine is equipped with 16 drilling

speeds.Remove the pulley cover securing screw.

Select the speed most suitable for the intended

application†.

Loosen both the locking knobs and adjust the

motor tension lever releasing the tautness across

the drive belts. Move the belt to the corresponding

sections of the motor, intermediate and spindle pulleys

ensuring the belts remain horizontal.

Apply pressure to the motor tension lever to

tension the drive belt. With the correct tension

achieved. Tighten both locking knobs .

Gently lower the pulley cover before tightening pulley

cover securing screw. Never attempt to operate the

drilling machine with the pulley cover open or not fully

secured.

CAUTION: Over tensioning the drive belt will

accelerate belt wear, increase the loading on drive

bearings and the motor possibly leading to premature

failure. Under tensioning the drive belt will lead to the

drive belt slipping and increased noise.

†As a general rule material with a softer composition

can be drilled faster as they cut more easily. Harder

materials require a slower speed as attempting to

make the hole at a high speed will result in the drill bit

over heating which may result in a poorly finished hole,

the bit annealing or the bit breaking.

Drilling wood too slowly can cause splintering.

FIG.11

Slow

1

Fast

16

Setting

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Speed

160 min

-1

240 min

-1

290 min

-1

350 min

-1

410 min

-1

480 min

-1

530 min

-1

590 min

-1

660 min

-1

720 min

-1

1,190 min

-1

1,350 min

-1

1,510 min

-1

1,970 min

-1

2,100 min

-1

3,000 min

-1

Drive Belt Position

Spindle

E - 5

D - 4

E - 5

C - 3

E - 5

D - 4

B - 2

C - 3

D -4

E - 5

A - 1

B - 2

C - 3

A - 1

B - 2

A - 1

Motor

1 - 1

1 - 1

2 - 2

1 - 1

3 - 3

2 - 2

1 - 1

2 - 2

3 - 3

4 - 4

2 - 2

3 - 3

4 - 4

3 - 3

4 - 4

4 - 4

FIG.10

MOTOR

PULLEY

INTERMEDIATE

PULLEY

SPINDLE

PULLEY

E

D

C

B

A

5

4

3

2

4

3

2

1

1

Loading ...

Loading ...

Loading ...