Loading ...

Loading ...

Loading ...

8. ASSEMBLY

8. ASSEMBLY

- 12 - - 13 -

FIG.1

WARNING: The headstock, and consequently

when fully assembled the drilling machine,

are extremely heavy. Care shall be taken

when manoeuvring. The use of a hoist should

be employed to ensure safety.

NOTE: Remove the plug from the socket

before carrying out adjustment, servicing or

maintenance.

8.1 BASE TO COLUMN -

FIGS. 1 - 3

Align the column base onto the base

and secure with the four 16mm bolts

.

NOTE: Do not overtighten the bolts as this

may crack the casting.

Lock column to column base with grub screw

$.

FIG.2

FIG.3

$

FIG.4

8.2 TABLE - FIG. 4

Slot the table into the table bracket and tighten

locking handle .

FIG.5

$

FIG.6

FIG.7

FIG.8

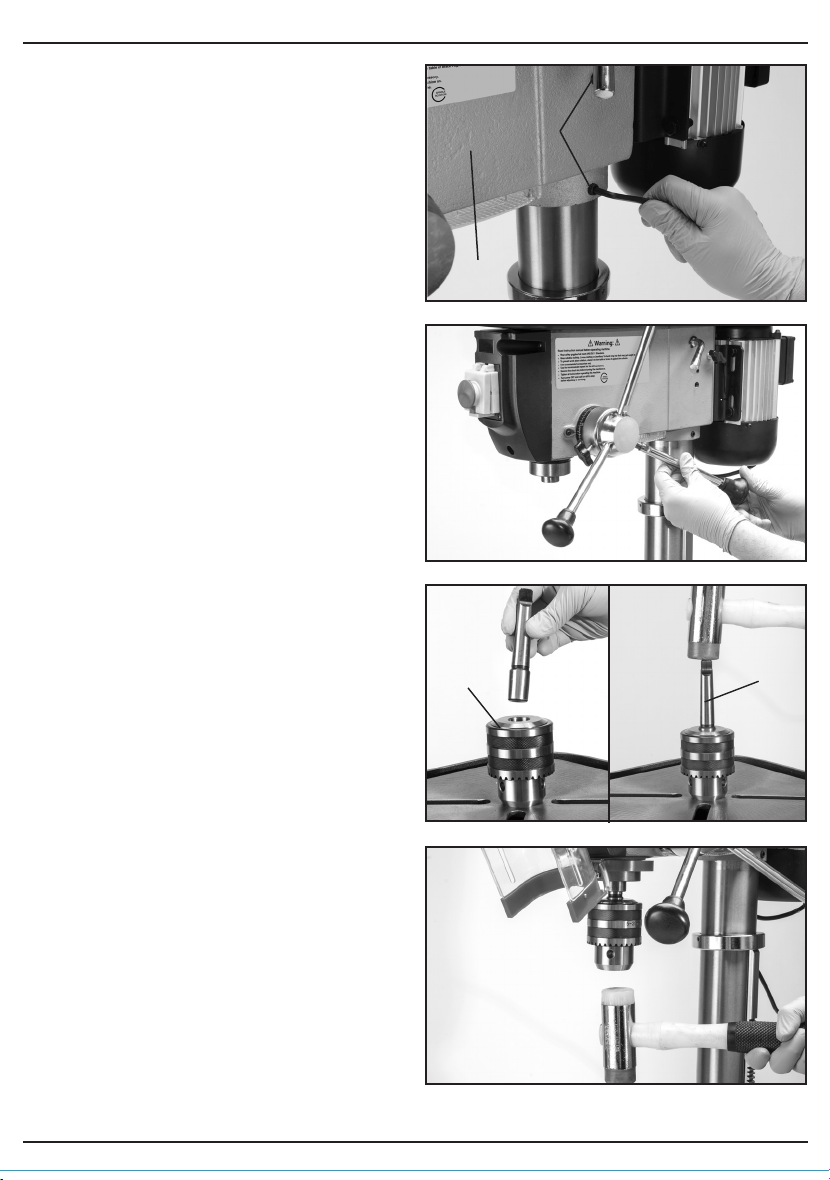

8.3 HEADSTOCK - FIG. 5

WARNING: The headstock assembly poses a

significant health and safety hazard while

being lifted and positioned into place. Seek

assistance.

Lift the headstock onto the top of the

column. When aligned and located down

onto the column fully, tighten grub screws

$ with the hex. key supplied.

NOTE: Adjust the drill head over the table

and base before securing. The use of a level

may be beneficial to improve accuracy.

8.4 PLUNGE HANDLES - FIG. 6

Screw plunge handles onto hub, hand

tighten.

8.5 CHUCK AND ARBOR -

FIGS. 7-8

The drill chuck, arbor and headstock spindle

join together with an interference fit formed by

the matched tapers of the mating surfaces.

Ensure all mating surfaces are clean as any

debris will cause the taper to mis-align

possibly resulting in the chuck or arbor

coming loose creating a potential hazard.

Using the chuck key provided open the chuck

until the jaws are completely recessed and

protected from damage.

Insert the short taper end of the arbor

into the back of chuck . A sharp tap with a

soft blow mallet will securely join them

together.

NOTE: Ensure the chuck is on a surface that

will not absorb the force of the mallet. If the

chuck does not mate securely, repeat the

process.

Insert the long taper end of arbor (P) into the

spindle. Rotate the chuck assembly until the

arbor locates allowing complete insertion.

Tap the chuck to securely locate it in place.

FIG.7b

Loading ...

Loading ...

Loading ...