Loading ...

Loading ...

Loading ...

9. SETTING THE BENCH DRILL

- 8 - - 17 -

5. HEALTH AND SAFETY INFORMATION

Have this tool repaired by a qualified person. This tool is designed to confirm to the relevant

international and local standards and as such should be maintained and repaired by someone

qualified; using only original parts supplied by the manufacturer: This will ensure the tool remains

safe to use.

5.2 SPECIFIC SAFETY INSTRUCTION FOR DRILL PRESSES USE

ADDITIONAL SAFETY INSTRUCTIONS FOR FLOOR DRILLS

MECHANICAL HAZARDS:

1. Crushing

When setting/changing a tool or maintaining the machine avoid crushing injuries sustained

between fixed and moving elements of the machine.

2. Cutting or Severing

At all times the workpiece shall be clamped as manual support will lead to injury.

3. Entanglement

Switch off the machine for maintenance, workpiece loading/unloading, swarf/chip removal,

cutting/lubrication fluid application as contact with rotating spindle or tool will cause

entanglement and possibly lead to injury and entrapment.

4. Impact

Ensure the workpiece is securely clamped at all times to avoid sudden movement (rotation) or

ejection causing injury. Ensure any special tools associated with tool exchange, i.e. chuck key

are removed prior to attempting to start the machine.

5. Stabbing, Cutting or Puncture Wounds

Take care when handling the tools and avoid contact with swarf and burrs created during

drilling as they are extremely sharp.

ELECTRICAL HAZARDS:

1. Contact with Live parts

During commissioning, maintenance and trouble shooting operations do not remove, open or

expose any electrical, terminal and control boxes due to the danger of electrocution. If the main

cable is damaged, unplug the machine immediately and have the cable replaced before

continuing.

AUDIBLE HAZARDS:

1. Hearing Loss

Wear ear defenders during operation to avoid damage to hearing, however ensure this does

not interfere with speech communications or audible warnings.

MATERIAL HAZARDS:

1. Contact and Inhalation

Wear personal protective equipment to avoid contact from harmful fluids, gases or dust thrown

or created during the drilling process.

2. Fire or Explosion

Do not drill or drill in the vicinity of flammable or combustible materials.

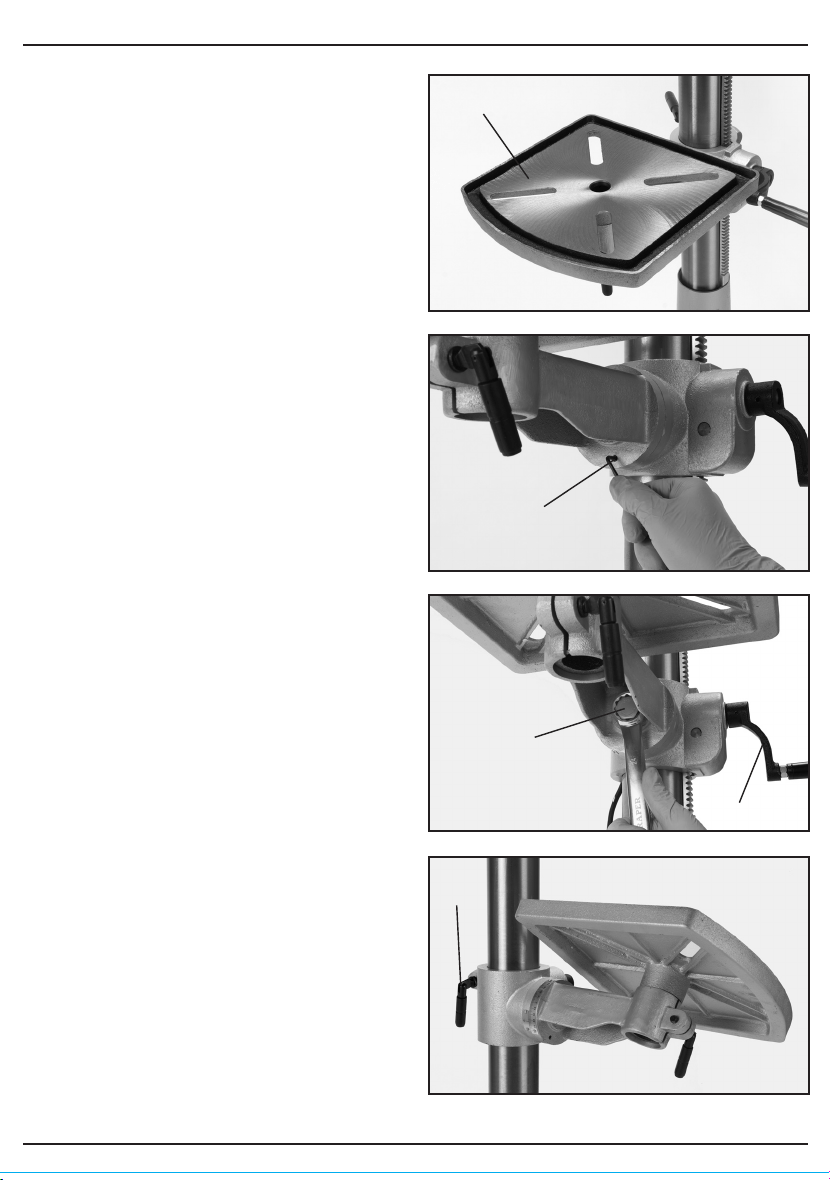

9.4 WORK TABLE ADJUSTMENT -

Figs. 16-19

For versatility, the work table can be

raised or lowered, tilted ±45° or rotated 360°

around the column.

To tilt the table, tighten nut & clockwise

until the locating pin can be removed from the

casting. Store in a safe location. Loosen the

24mm bolt %.

Adjust the table’s degree of tilt and re-secure

with locking bolt %. Use the scale as a

guide. Alternatively use a protractor off the

table to the drill bit for more accuracy.

When the table is back in a level position

insert the location pin for the factory setting.

Move the nut along the thread until the end of

the thread is protected by the nut, allowing

use of a small hammer to tap the pin in place.

To raise/lower the table working height,

loosen locking handle and turn the

height adjustment crank handle to raise

or lower the table. Alternatively while locking

handle is loose the table can be rotated

180° to further increase the distance between

the chuck and workpiece. When the

adjustments are complete re-secure locking

handle .

The slots in the work table and base can

accommodate locking bolts to secure a small

vice enabling safe clamping of the workpiece.

CAUTION: A drill bit snagging on a piece of

work will violently grab the piece of material,

whipping it round and is likely to result in

personal injury. Always ensure the workpiece

is securely clamped.

FIG.16

FIG.17

FIG.18

%

FIG.19

&

Loading ...

Loading ...

Loading ...