Loading ...

Loading ...

Loading ...

13

www.napoleongrills.com

N415-0272-AU JAN 24.18

WARNING! Always wear protecve gloves and safety glasses when cleaning your grill.

WARNING! Turn o the gas at the source and disconnect the unit before servicing. To avoid the

possibility of burns, maintenance should be done only when the grill is cool. A leak test must be

performed annually and whenever any component of the gas train is replaced or gas smell is present.

Maintenance Instrucons

Tube Burner: The burners are made from heavy wall 304 stainless steel, but extreme heat and a corrosive

environment can cause surface corrosion to occur. This can be removed with a brass wire brush.

CAUTION! Beware of Spiders.

Spiders and insects are aracted to the smell of Universal Liqueed Petroleum Gas and Natural Gas.

The burner is equipped with an insect screen on the air shuer, which reduces the likelihood of insects

building nests inside the burner but does not enrely eliminate the problem. A nest or web can cause the

burner to burn with a so yellow or orange ame or cause a re (ashback) at the air shuer beneath the

control panel. To clean the inside of the burner, it must be removed from the gas grill: Remove the screw

that aaches the burner to the back wall. Slide the burner back and upwards to remove. Cleaning: Use

a exible venturi tube brush to clean the inside of the burner. Shake any loose debris from the burner

through the gas inlet. Check the burner ports and valve orices for blockages. Burner ports can close over

me due to cooking debris and corrosion, use an opened paperclip or the supplied port maintenance bit

to clean them. Drill out blocked ports using this drill bit in a small cordless drill. The ports are easier to

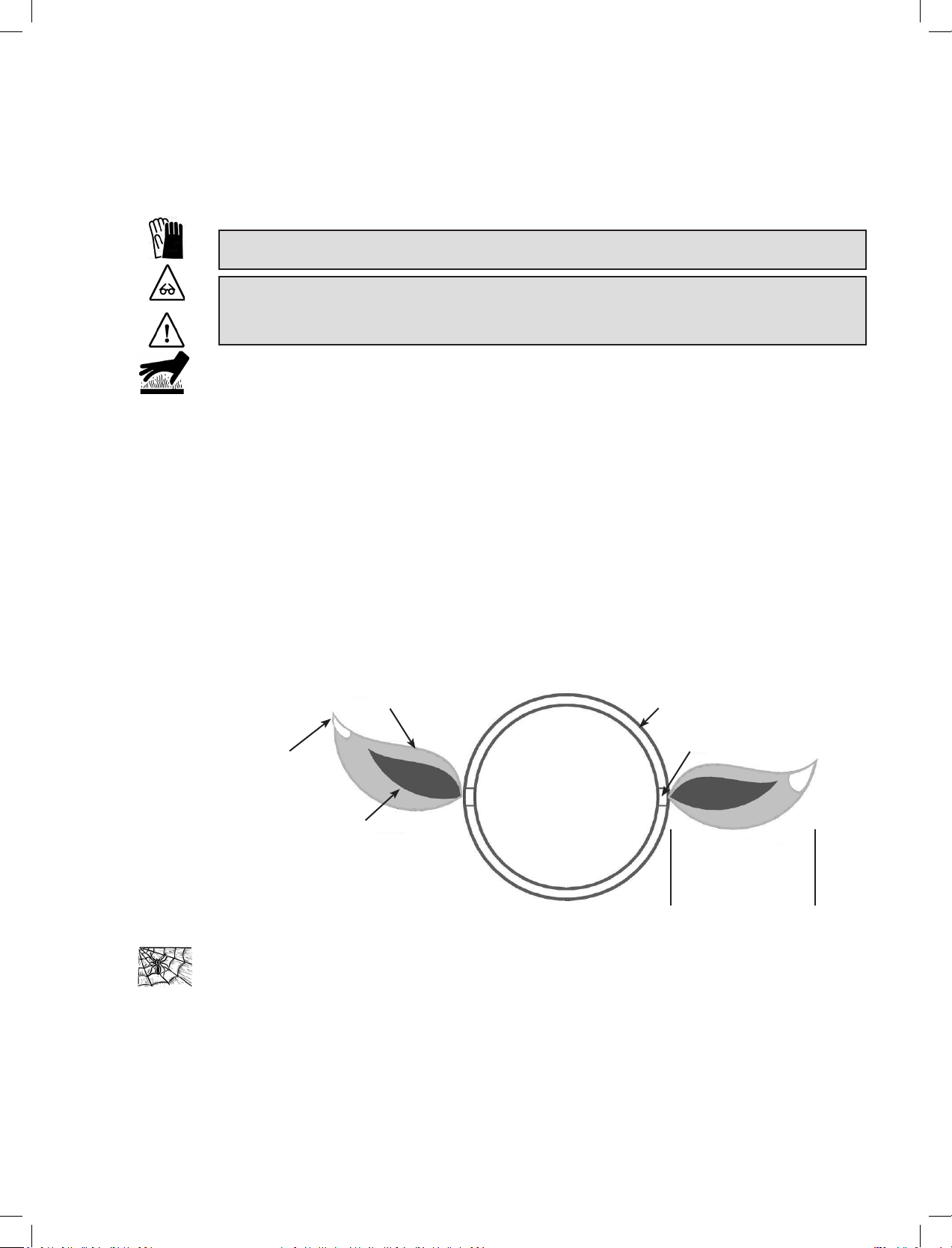

Light Blue

Yellow Tipping

Dark Blue

Burner

Burner Port

Approximately

1/2” (13mm)

We recommend this gas grill be thoroughly inspected and serviced annually by a qualied service person.

At all mes keep the gas grill area free from combusble materials, gasoline and other ammable vapors

and liquids. Do not obstruct the ow of venlaon and combuson air. Keep the cylinder enclosure

venlaon openings (located on the cart sides and at the front and back of the boom shelf) free and

clear from debris.

Combuson Air Adjustment: (This must be done by a qualied gas installer.) The air shuer is factory

set and should not need adjusng under normal condions. Under extreme eld condions, adjustments

might be required. When the air shuer is adjusted correctly the ames will be dark blue, pped with

light blue and occasionally yellow.

• With too lile air ow to the burner, the ames are lazy yellow and can produce soot.

• With too much air ow, the ames li erracally and can cause dicules when lighng.

Adjusng the air shuer:

1. Remove cooking grids and sear plates and leave lid open.

2. Loosen air-shuer lock screw located at the mouth of the burner and open or close air shuer as

required. The normal opening sengs are:

Main Tube Burner Universal Liqueed Petroleum Gas 5/32” (4mm)

Natural Gas 5/32” (4mm)

*Infra-Red burners have no air adjustment.

3. Light the burners and set to high. Visually inspect burner ames. When the shuers are set correctly,

turn burners o, ghten locking screws, and replace removed parts. Ensure that the insect screens are

installed.

Loading ...

Loading ...

Loading ...