Loading ...

Loading ...

Loading ...

4-1

4. ALIGNMENT AND ADJUSTMENTS

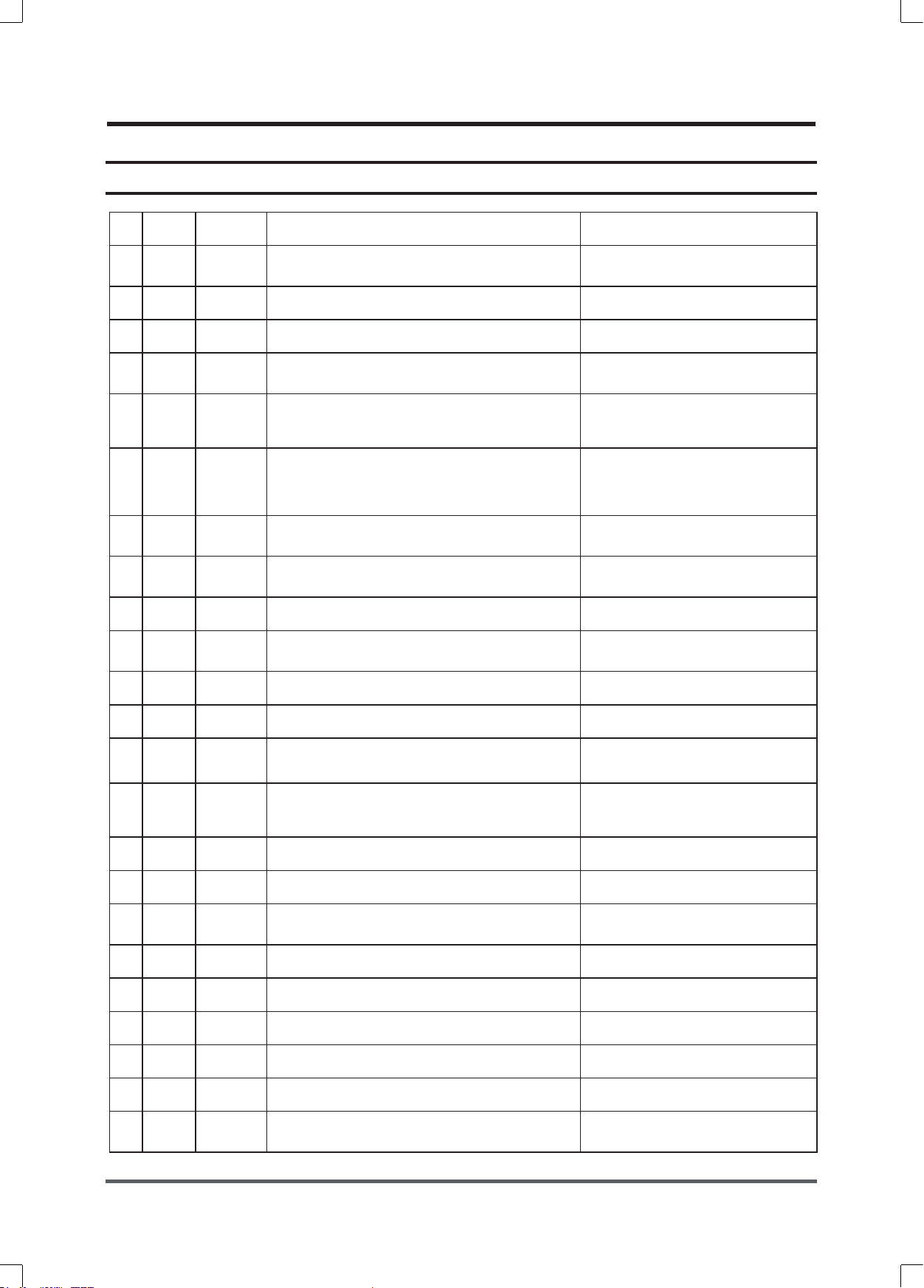

4-1. GENERAL ERROR FUNCTION

NO

LED

Display

Diagnostic

Code

Description Corrective Action

1 nd 1

The water level fails to drop below the Reset Water Level

within 15 minutes.

Go to “ Will Not Drain” Troubleshooting

Section.

2 LO 2

Door fails to unlock after 3 attempts.

Go to “ Will Not Unlock” Troubleshooting

Section.

3 nF 3

When the filling continues for more than 16 minutes or there

is no change of water level for 3 minutes

Go to “ No Water Fill” Troubleshooting

Section.

4 FL 4

Door fails to lock after 3 attempts.

Go to “ Will Not Lock” Troubleshooting

Section.

5 LE 8

Water Level Sensor Trouble.

(When the input signal from the water level sensor is out of

range, the unit will send out beeping sounds and halts the

cycle.)

Go to “No Water Fill” Troubleshooting Section.

6 OE E

A fault is detected in the water level sensor.

Data (frequency) shows the water level is at or above the

overflow water level. (When this condition is detected, the

machine will automatically starts draining water until the water

level falls below the overflow water level)

First check to see that all of water valves are

not stuck. If water valves are OK, check water

level sensor.

7 dc 10

Unbalance or cabinet bump is detected during final spin,

which prevents the drum from spinning over 400 rpm. (Never

exceeds 400 RPM due to unbalanced load)

Go to “Wet Clothes” Troubleshooting Section.

8 - 11

EEPROM Fault. (Program settings are being reset.)

Go to “EEPROM Clear Mode” If display

shows “FAiL”,Replace Machine Control

Board.

9 E2 15

Jammed Key.(When key input signals are coming out for

more than 30 seconds, it is regarded as a jam.)

Check all of keys. If A key is sensed to be

pressed, all keys will do not respond.

10 dL 18

Door is detected as open when the motor is operating.

Check for loose wire connections.

Go to “Quick Test Mode” and then do Door

lock/Unlock Test and Motor Test.

11 dS 22

Door is detected as open while it is trying to lock the door.

Go to “Quick Test Mode” and then do Door

Lock/Unlock Test

12 bE 25

Motor hall sensor signals come out without motor operation. Replace Machine Control Board.

13 tE 29

Abnormal high/low temperature or resistance (Thermal

sensor or PBA) resistance.

Go to “ Board Input Test” and check Water

Temperature. Check loose or pinched wires.

Replace PCB or thermistor.

14 E3 2E

MICOM is attempting to drive the motor but is not getting any

response signals from the hall sensor. Visual check shows

motor is not running. (Locked, Defective Hall Sensor or

Overload)

Evaluate wire harness for loose or unhooked

connections. Go to “ Quick Test Mode” and

test Motor.

15 Sr 34

System Relay (Main Relay) Failure. (PCB does not notice the

relay operation when there should be.)

Replace PCB.

16 Hr 36

Heater Relay Failure (No Heater Relay Check Signal) Replace PCB

17 3E 3E

Over-current is detected. Motor won’t turn.

(IPM detects over-current.)

Evaluate wire harness for loose or unhooked

connections.

Go to “ Quick Test Mode” to test Motor.

18 2E 91

Voltage for motor control bus is over specified limit. Replace PCB

19 2E 92

Voltage for motor control bus is under specified limit. Replace PCB

20 8E 8E

MEMS Sensor Failure. (No MEMS Sensor Check Signal)

Check MEMS PCB ,Main PCB & Wire-

harness

21 7E 7E

Silver Care Kit (Silver Care PCB) Failure.

Check Silver Care PCB ,Main PCB & Wire-

harness

22 PF -

It occurs when there is power failure during the washing.(“PF”

is not an error. It is to inform the user of power failure.)

-

23 SUdS -

Suds is detected during the washing session. (“SUdS” is not

an error. If the washer is in suds period, “SUdS” will light up

instead of remaining time.)

Guide a user to reduce amount of detergent

usage.

Loading ...

Loading ...

Loading ...