Loading ...

Loading ...

Loading ...

6-16

6-16

Electrical servicing

Speed sensor

System check

NOTICE

Before starting this inspection, check the inspection of

the speedometer system.

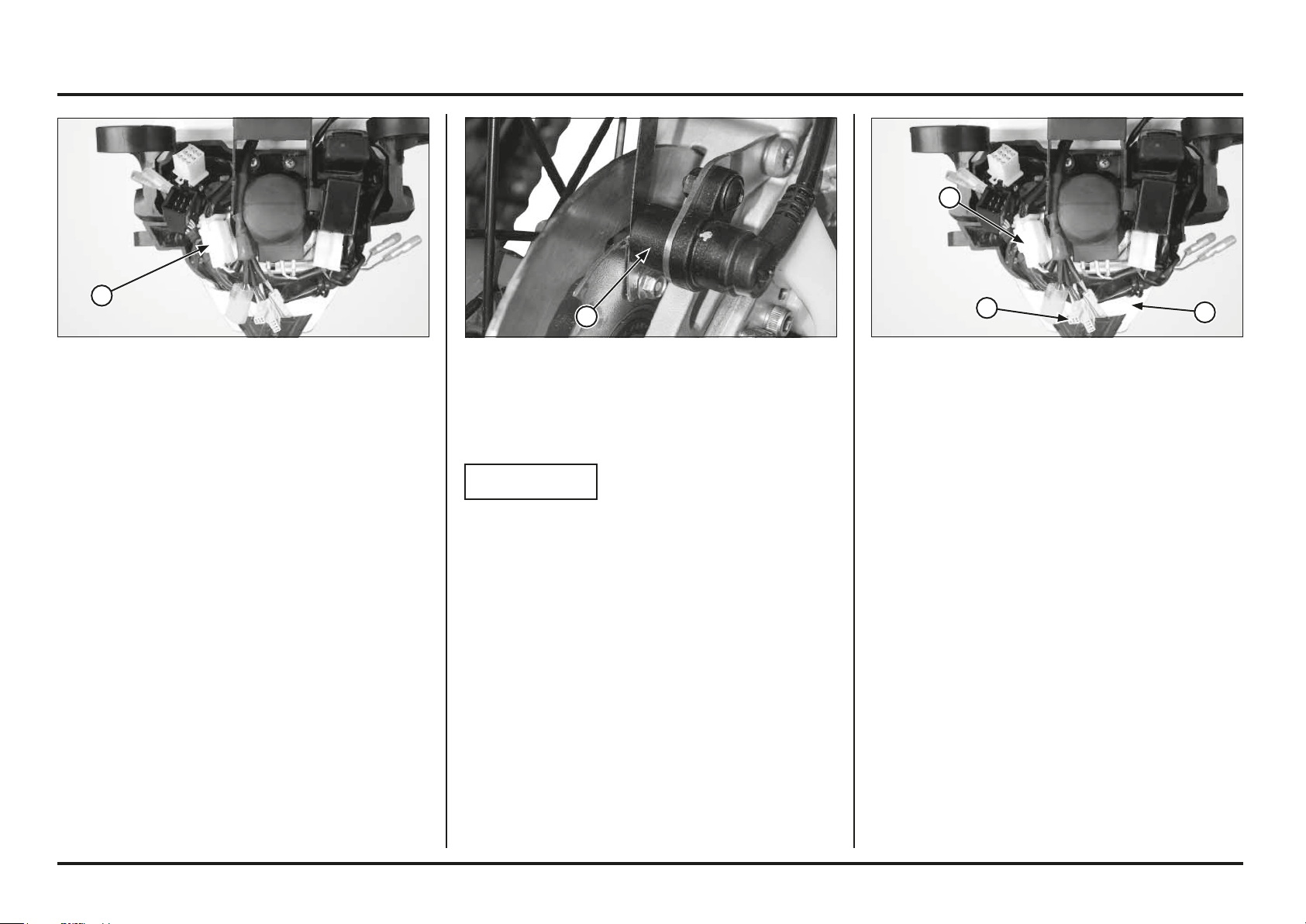

Checking the air gap

Safely support the motorcycle with a lifting device or

equivalent and raise the wheel off the ground.

Measure the gap (air gap) between the sensor and the

pulse generator ring at different points by turning the

wheel slowly.

It must be within the specification.

Standard: 0.5 – 1.5 mm (0.031 – 0.035 in)

The air gap cannot be adjusted.

If it is not within the specification, check whether there

are deformities, damage or if any of the parts assembled

are loose.

(1) SPEED SENSOR(1) CONNECTOR 6P

Power input line

Measure the voltage between the connector 6P of the

speedometer and the ground.

Connection: White/Red(+) and Ground (–)

With the engine on, around 12V should be received.

If there is no voltage, check the existence of an open

circuit in the White/Red wire.

Ground line

Measure the continuity between the connector 6P of the

speedometer and the ground.

Connection: Green and Ground

There must be continuity at all times.

If there is no continuity, check the existence of an open

circuit in the green wire.

(1) HOUSING FOR THE UPPER HEADLIGHT

(2) CONNECTOR 6P

(3) CONNECTOR 3P

Checking the speed sensor

Remove the housing for the upper headlight.

Check if there are loose or defective contacts in the

connector 3P (white) of the speed sensor.

Connect the connector 3P (white) of the speed sensor.

Start the engine.

Measure the voltage between the terminals of the

connector 3P (white) of the speed sensor on the wire

side.

Connection: Red (+) and Black (–)

Standard: 5V.

If the standard voltage appears, replace the speed sensor.

If there is no standard voltage, check the following:

The blue wire in case there is an open circuit.

The red wire in case there is an open circuit.

Speedometer.

1

1

3

2

1

Loading ...

Loading ...

Loading ...