Loading ...

Loading ...

Loading ...

5-7

5-7

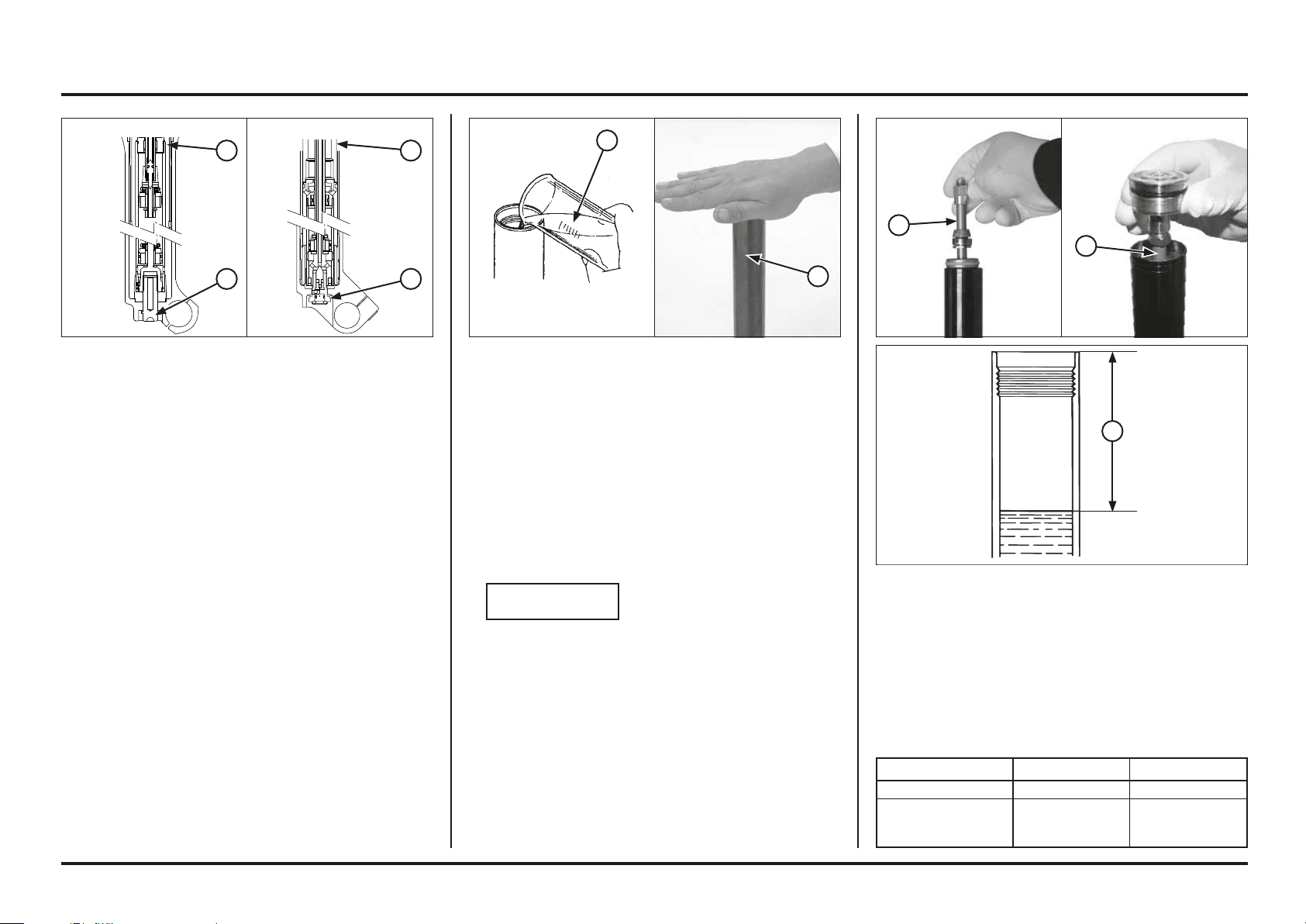

Frame servicing

(1) FORK DAMPER ROD

(2) OIL LEVEL

2. Pump the damper rod 8 - 10 times.

3. Make sure no air in fork damper by slowly pull the

damper rod up. If the resistance is felt at the top end,

pump the damper rod again.

Wait 2 – 3 minutes before measuring the oil level.

Measure the oil level from top of the fork tube, with the

fork fully compresed.

ED/3ED

ED/3ED

2ED/4ED

2ED/4ED

Standard oil level

50 mm (1.9 in) 38 mm (1.5 in)

Oil capacity

(orientative)

400 cm

3

(13.5 US oz)

(14.1 Imp oz)

410 cm

3

(13.9 US oz)

(14.4 Imp oz)

Pour recommended fork fluid in the fork leg.

Specified fork fluid:

ED/3ED: OJ Racing Special Fork Oil Type 01 (SAE 5W)

or equivalent

2ED/4ED: Showa SS05 (SAE 5W) or equivalent

Bleed the air as follows:

1. Extend the fork without bringing to its maximum exten-

sion. Cover the top of the fork tube with your hand and

compress the fork slowly several times.

NOTICE

Totally extended fork may cause oil leakage.

(1) FORK FLUID

(2) FORK TUBE

Hold the axle holder in a vise protected with a piece of

woods or soft jaws to avoid damage.

Do not overtighten the vise.

Install the right fork center bolt with a new sealing washer.

Hold the fork damper using the special tool (2ED/4ED),

then tighten the right fork center bolt to the specified

torque.

Tool:

Fork damper holder 89515–NN3–821

Torque:

ED/3ED: 23.5-25.5 N•m (2.4-2.6 kgf•m)

2ED/4ED: 34 N•m (3.5 kgf•m)

(1) FORK DAMPER

(2) RIGHT FORK CENTER BOLT

2

1

1

1

2

ED/3ED

ED/3ED

2ED/4ED

2ED/4ED

22

11

ED/3ED

ED/3ED

2ED/4ED

2ED/4ED

Loading ...

Loading ...

Loading ...