Loading ...

Loading ...

Loading ...

Front Suspension Adjustments

(cont’d)

Adjustments for Competition 131

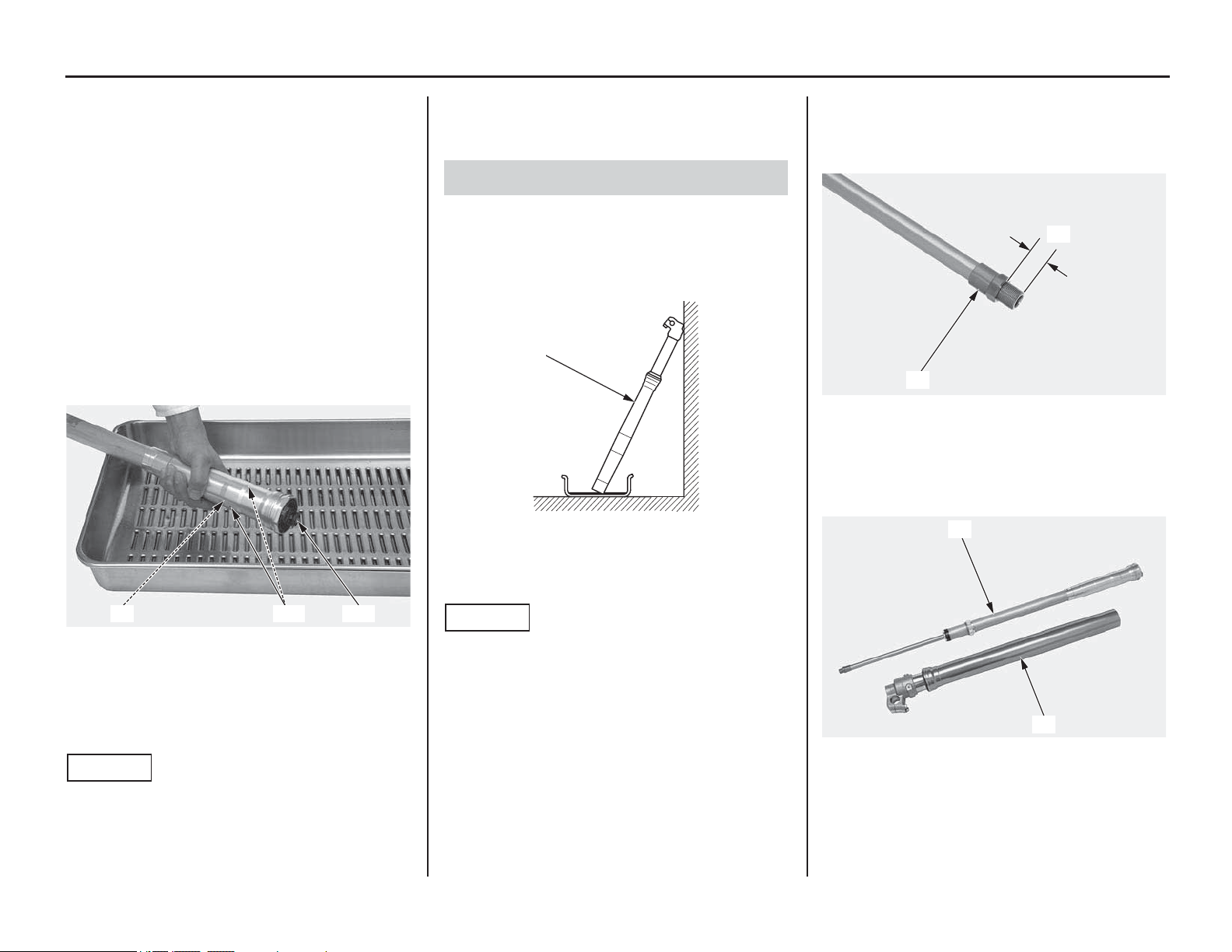

13. Drain the extra oil from the oil holes (11) of the

fork damper oil chamber (3).

By doing above procedure, about 0.2 US oz (5

cm

3

) of fork oil will be drained from the fork

damper oil chamber through the oil hole and cause

10.1 US oz (300 cm

3

) of fork oil to be left in the

fork damper oil chamber.

14. Blow out the oil from the fork damper oil

chamber using compressed air to the oil hole.

Wipe the oil completely off the fork damper.

If you cannot use compressed air, remove the

pressure release screw (12).

Hold the fork damper up side down for 20

minutes and drain the oil from the fork damper

oil chamber.

Pour the drained oil into a suitable container and

dispose of it in an approved manner (page 156).

NOTICE

Improper disposal of drained fluids is harmful to

the environment.

15. Install and tighten the pressure release screw to

the specified torque:

1.0 lbf·ft (1.3 N·m, 0.1 kgf·m)

1. Drain the fork oil from the fork assembly (1)

by placing it upside down.

(About 0.2 US oz (7 cm

3

) of fork oil will be left

in the outer tube/slider when it is left inverted

for about 20 minutes at 68°F/20°C)

To properly dispose of drained fluids, refer to You

& the Environment on page 156.

NOTICE

Improper disposal of drained fluids is harmful to

the environment.

2. Tighten the fork center bolt lock nut (2) fully

and measure the thread length (A) as shown.

Standard: 0.39 – 0.47 in (10.0 – 12.0 mm)

Wipe the oil completely off the fork damper.

3. Install the fork damper assembly (3) to the fork

assembly (1).

4. Temporarily tighten the fork damper assembly

to the fork assembly.

(3) fork damper oil chamber

(11) oil holes

(12) pressure release screw

(3) (11) (12)

Right Fork Assembly

(1) fork assembly

(1)

(2) fork center bolt lock nut (A) thread length

(1) fork assembly

(3) fork damper assembly

(2)

(A)

(3)

(1)

Loading ...

Loading ...

Loading ...