Loading ...

Loading ...

Loading ...

Servicing Your Honda 97

Suspension

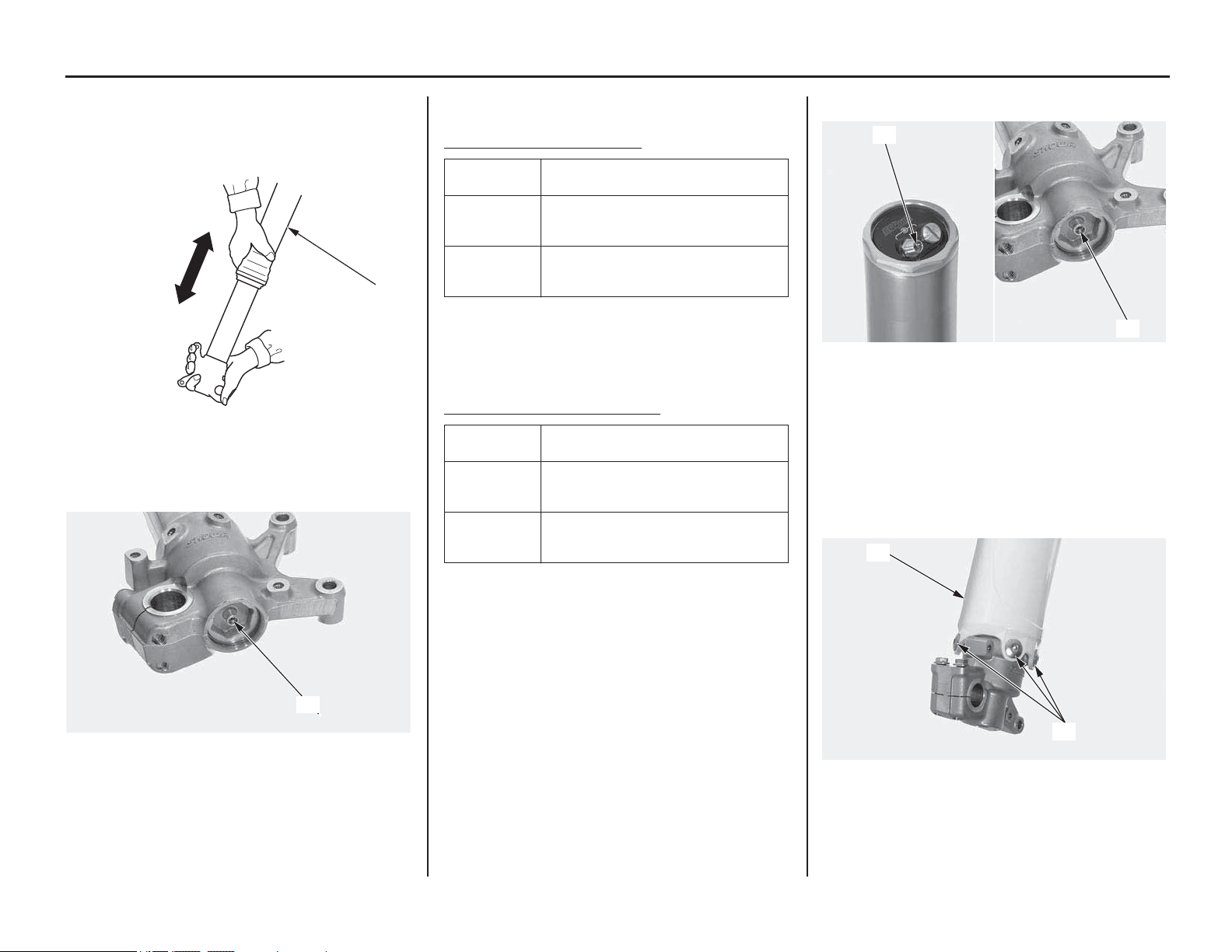

7. Bleed the fork oil from the balance chamber air

valve by pumping the outer tube (5) several

times.

8. Install the valve center (4) of the balance

chamber air valve.

9. Apply air pressure to the inner chamber and

check that there is no air leakage.

Inner Chamber Air Pressure:

When applying air pressure to the inner chamber,

the fork will be extended.

10. Apply air pressure to the balance chamber and

check that there is no air leakage.

Balance Chamber Air Pressure:

When applying air pressure to the balance

chamber, the fork will be shortened.

11. Install and tighten the balance chamber valve

cap to the specified torque:

0.4 lbf·ft (0.5 N·m, 0.1 kgf·m)

12. Clean the threads of the fork protector socket

bolts (1) and axle holder thoroughly.

Apply locking agent to the bolt threads.

Install the fork protector (2) and fork protector

socket bolts.

Tighten the fork protector socket bolts to the

specified torque:

5.2 lbf·ft (7 N·m, 0.7 kgf·m)

(5) outer tube

(4) balance chamber air valve center

(5)

(4)

Standard air

pressure

174 psi (1,200 kPa, 12.2 kgf/cm

2

)

Maximum air

pressure

(stiff)

189 psi (1,300 kPa, 13.3 kgf/cm

2

)

Minimum air

pressure

(soft)

131 psi (900 kPa, 9.2 kgf/cm

2

)

Standard air

pressure

163 psi (1,125 kPa, 11.5 kgf/cm

2

)

Maximum air

pressure

(soft)

189 psi (1,300 kPa, 13.3 kgf/cm

2

)

Minimum air

pressure

(stiff)

145 psi (1,000 kPa, 10.2 kgf/cm

2

)

(3) air valves

(1) fork protector socket bolts

(2) fork protector

(3)

(3)

Inner chamber: Balance chamber:

(2)

(1)

Loading ...

Loading ...

Loading ...